Stable powder supply method and device based on internal and external cyclone fluidized powder

A powder supply device and external swirl technology, which are applied in the burner, combustion method, transportation and packaging of powder fuel, can solve the problem of large particle force, difficult to stabilize and uniform large flow supply for a long time, adhesion, etc. Channeling, agglomeration and other problems, to achieve the effect of improving the fluidization effect and preventing the bad fluidization phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

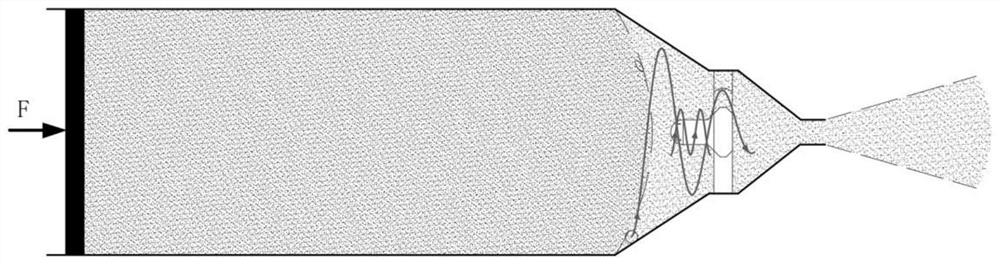

[0034] A stable powder supply method based on internal and external cyclone fluidized powder in this embodiment is applied in the engine ignition experiment using powder as one of the fuels, and powder fuel is supplied to the combustion chamber of the test engine. By designing a reasonable device size, The piston propulsion speed, fluidizing gas flow rate and pressure can realize the efficient and stable delivery of ultrafine and viscous powders in a high back pressure environment. The principle is as follows figure 1 shown.

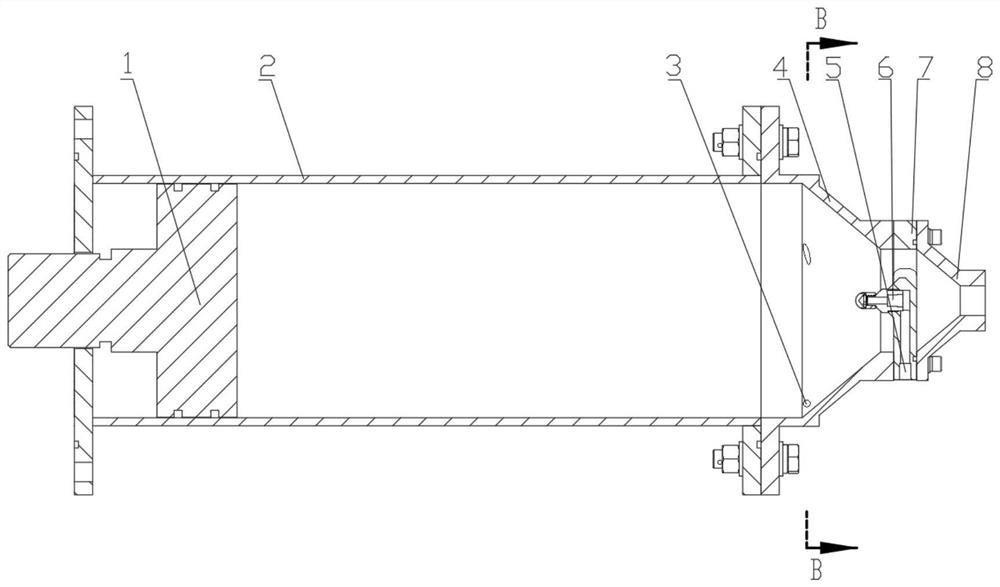

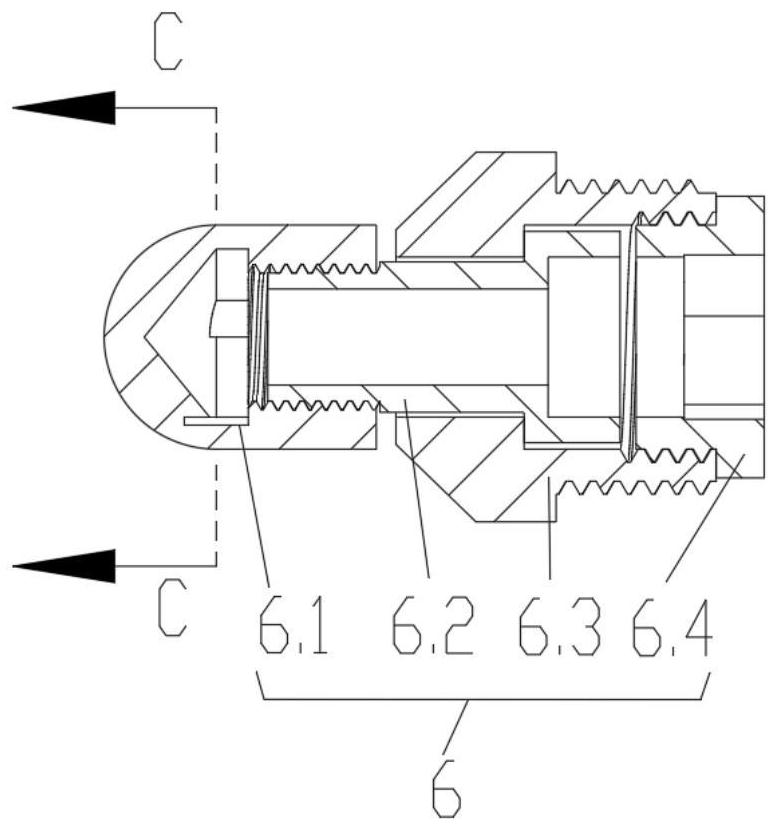

[0035] The described stable powder supply device based on internal and external cyclone fluidized powder is as follows: figure 2 As shown, it includes the powder storage and supply section and the powder fluidization section: the powder storage and supply section includes the piston 1 and the storage tank 2; Fluidization gas inlet 5, nozzle 6, nozzle installation block 7 and constriction outlet 8 of gas-powder two-phase flow.

[0036] The rear piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com