Binding installation equipment for building steel frame

A technology for installing equipment and steel frames, applied in the field of building pouring, can solve the problems of workers' bodies being easily damaged, low binding efficiency, easy to be scratched by steel wires, etc., to reduce manual grinding time, avoid wire scratches, reduce physical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

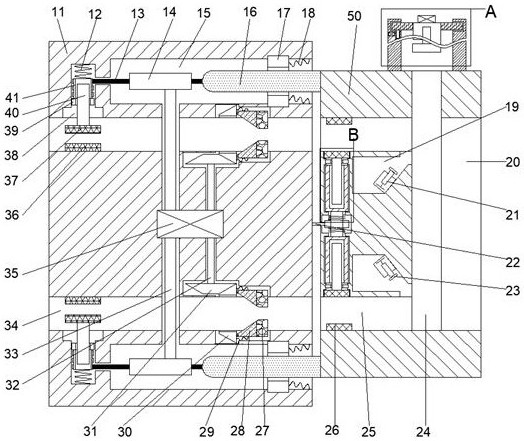

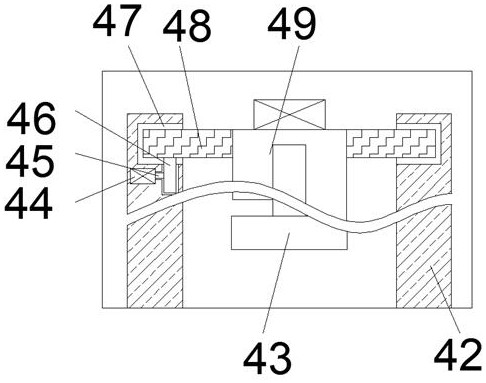

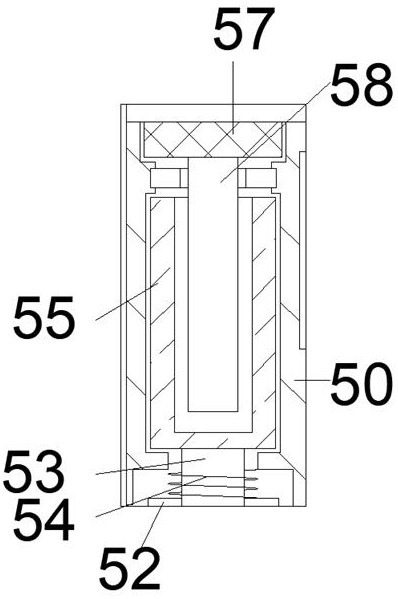

[0015] Combine below Figure 1-3 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0016] A binding installation device for building steel frames according to the present invention includes a frame 11, and two moving cavities 34 are arranged on the left and right inside the frame 11, and the two moving cavities 34 are separated by the frame. The center of 11 is a symmetrical center and is symmetrically distributed up and down. The inner wall of the side of the moving chamber 34 close to the center of the frame 11 is fixed with a fixed limit block 36, and the end of the moving chamber 34 is far away from the center of the frame 11. A rotating chamber 38 is connected to it, and the end of the moving chamber 34 away from the center of the frame 11 is slid to be provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com