Valve for dosing fluid

A fluid and valve needle technology, which is applied in the field of metering fluid valves, can solve the problems of valve characteristic changes, stopper wear, etc., achieve reliable functions, improve injection characteristics, improve configuration and working methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

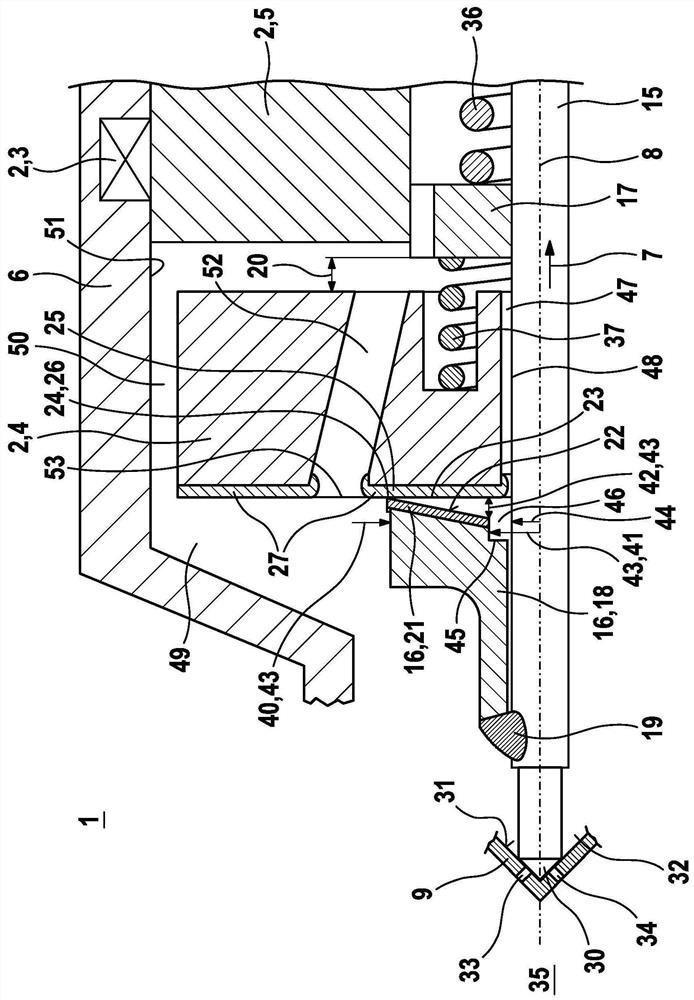

[0022] figure 1A schematic sectional view of a detail of a valve 1 for metering fluids according to a preferred embodiment is shown. In particular, valve 1 can be designed as fuel injection valve 1 . A preferred application is a fuel injection system, in which such a fuel injection valve 1 is designed as a high-pressure injection valve 1 and is used to inject fuel directly into an associated combustion chamber of an internal combustion engine. The configuration of the valve 1 is particularly suitable for liquid fluids, especially liquid fuels such as gasoline or diesel, or for liquid mixtures with at least one fuel.

[0023] The valve 1 has an electromagnetic actuator 2 comprising a solenoid coil 3 , an armature 4 and an inner pole 5 . When solenoid coil 3 is energized, the solenoid circuit is closed via housing (valve housing) 6 , armature 4 and inner pole 5 , whereby armature 4 is actuated along longitudinal axis (axis) 8 of housing 6 in opening direction 7 . The housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com