Empty box stacking machine intelligent control system with precise positioning function

An intelligent control system, precise positioning technology, applied in the direction of comprehensive factory control, cleaning methods using tools, cleaning methods and utensils, etc., can solve problems such as unstable center of gravity, difficulty in precise control of alignment, hidden safety hazards, etc. Accuracy, reduce the occurrence of hazards, improve the efficiency of the stacking box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

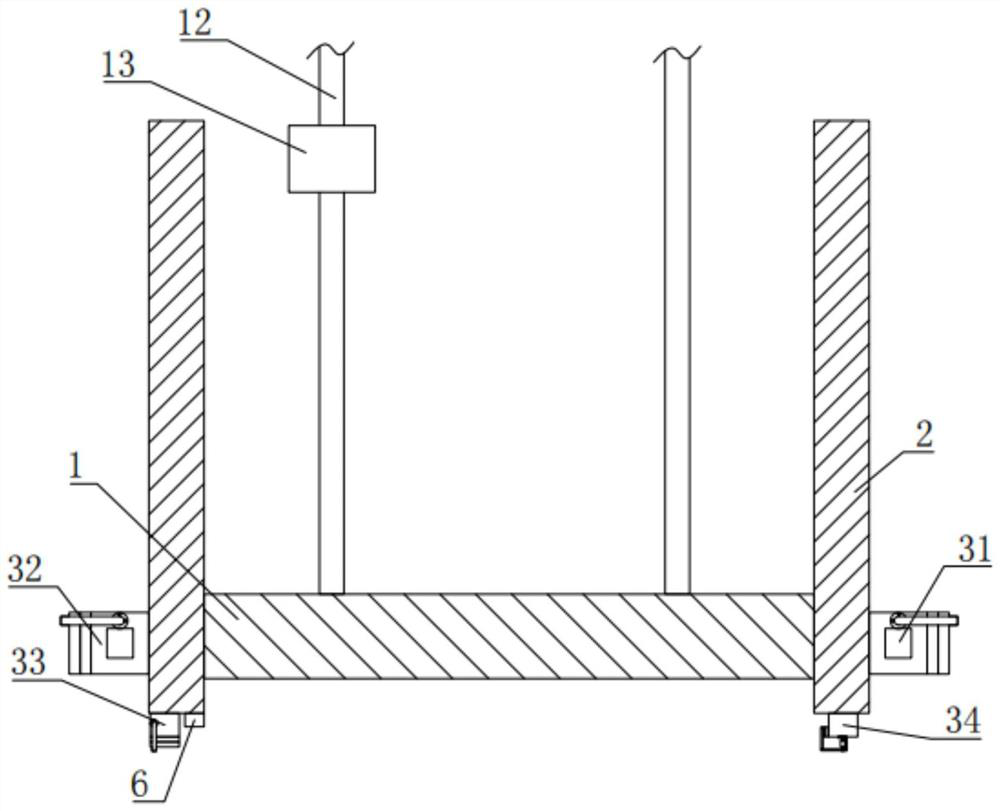

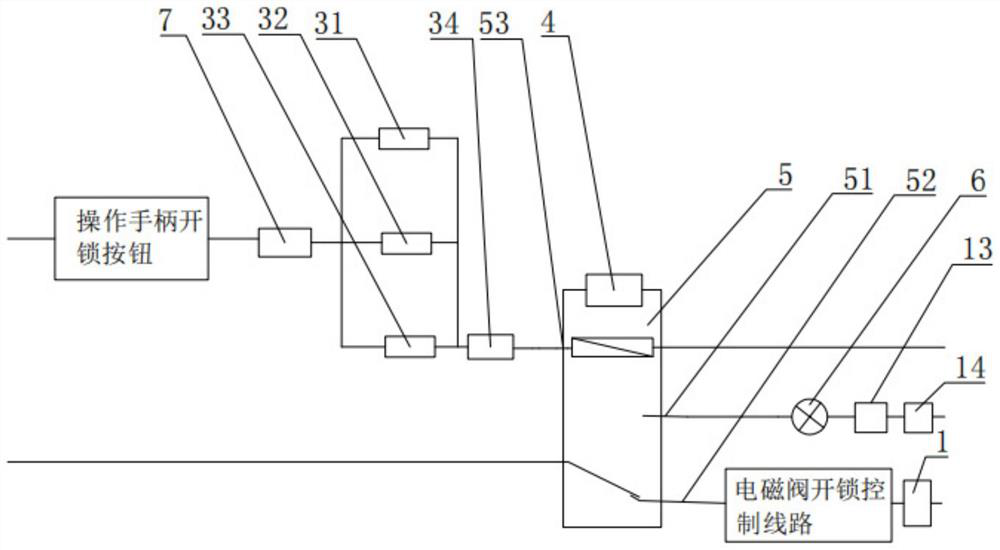

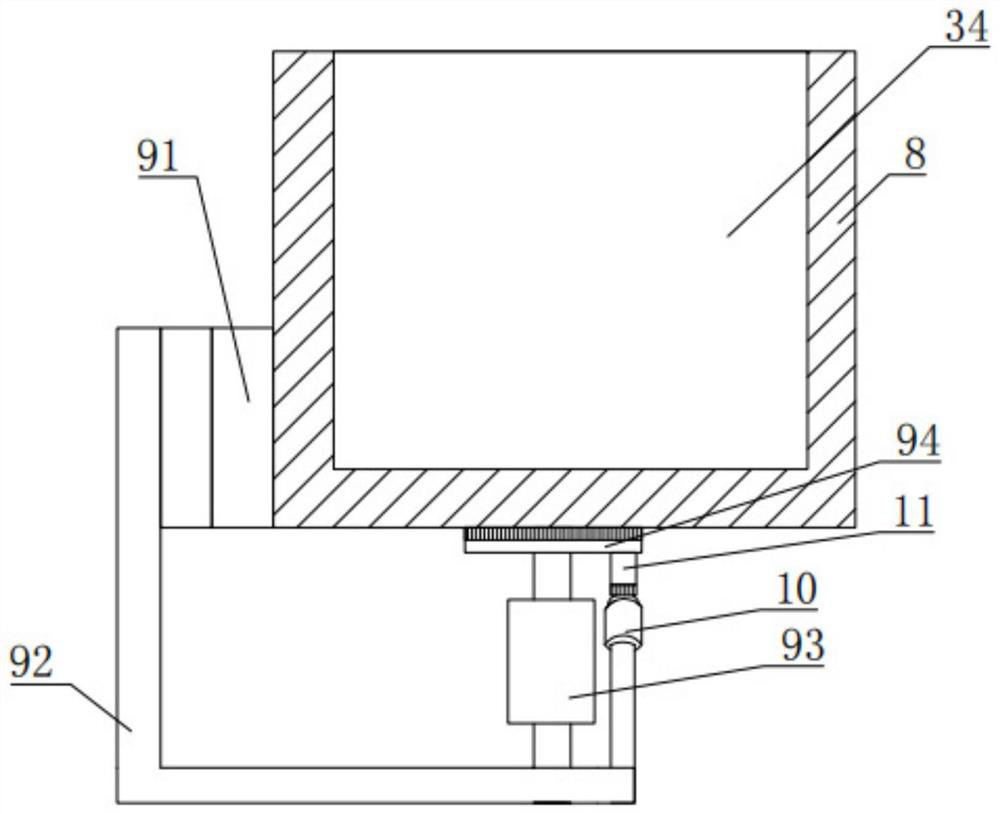

[0025] An intelligent control system for empty container stackers with precise positioning function, such as Figure 1-2 As shown, a spreader 1 including a stacker is provided with uprights 2 on both sides of the spreader 1, and a first sensor 31 and a second sensor 32 are respectively fixed under the two uprights 2 for detecting the flatness of the side surface of the container below. The orientation of the sensor 31 and the second sensor 32 is 45° horizontally downward, a third sensor 33 for detecting the front and rear alignment of the upper and lower containers is provided under a column 2, the third sensor 33 is oriented horizontally downward 60°, and another A fourth sensor 34 for detecting the height of the spreader 1 from the ground is provided below a column 2 , the fourth sensor 34 is oriented vertically downward, the first se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com