Small in-bore environment-sensitive mechanism

An internal environment and sensitive technology, applied in the field of fuze, to achieve the effect of reducing the axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

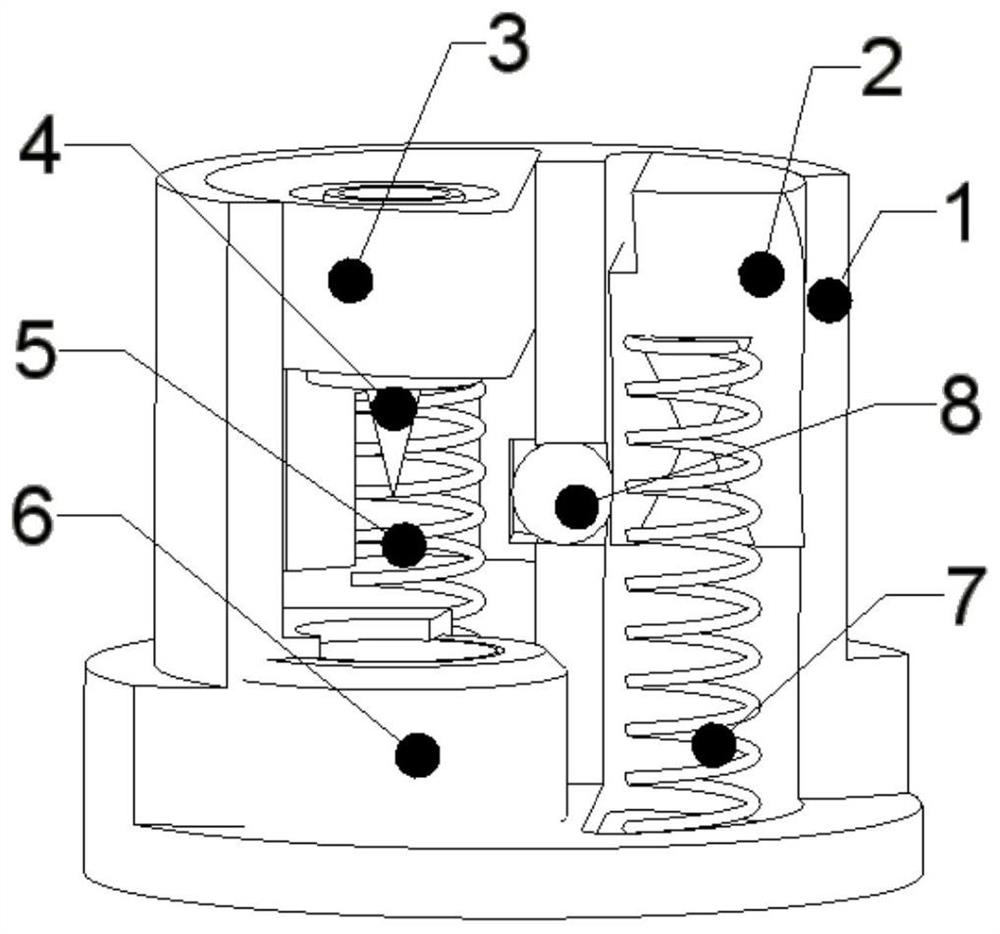

[0026] The low-overload in-bore ignition mechanism in this embodiment, as attached figure 1 , mainly includes: base 1, inertia block 2, firing pin seat 3, firing pin 4, firing pin spring 5, acupuncture cap 6, inertia block spring 7, steel ball 8.

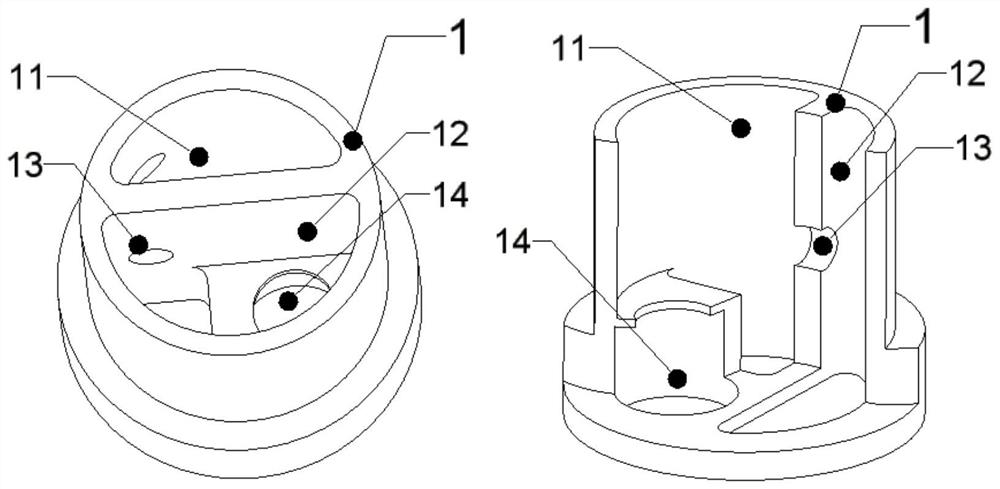

[0027] The base 1 is as attached figure 2 , the shape is a structure of revolution, and there are two semi-cylindrical cavities axially penetrating inside. The first semi-cylindrical cavity 11 is used to install the inertial mass 2 and constrain the inertial mass 2 to move axially in the cavity 11 . The second semi-cylindrical cavity 12 is used for installing the firing pin seat 3 and constraining the axial movement of the firing pin seat 3 in the cavity 12 . The radial through hole 13 is used to install the steel ball 8, and the radial through hole 13 communicates with the first semi-cylindrical cavity 11 and the second semi-cylindrical cavity 12;

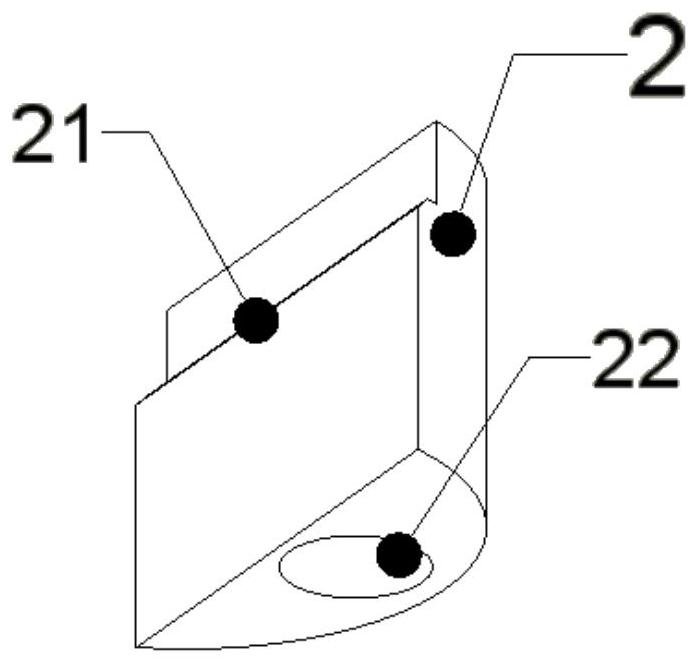

[0028] The inertial block 2 is as attached image 3 , is a semi-cylindrical st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com