Image position deviation compensation processing method, system and device in alignment assembly of marker lamp and lens, processor and storage medium

A technology for marking lamps and lenses, which is applied in image data processing, image analysis, image enhancement, etc., and can solve problems such as inaccurate pasting, inaccurate alignment, and deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

[0057] Before describing the embodiments according to the present invention in detail, it should be noted that in the following, relative terms such as first and second are only used to distinguish one entity or action from another entity or action, and do not necessarily require or Any actual such relationship or order between such entities or actions is implied. The terms "comprising", "comprising" or any other variant are intended to cover a non-exclusive inclusion whereby a process, method, article or apparatus comprising a set of elements includes not only those elements but also other elements not expressly listed elements, or elements inherent in such a process, method, article, or apparatus.

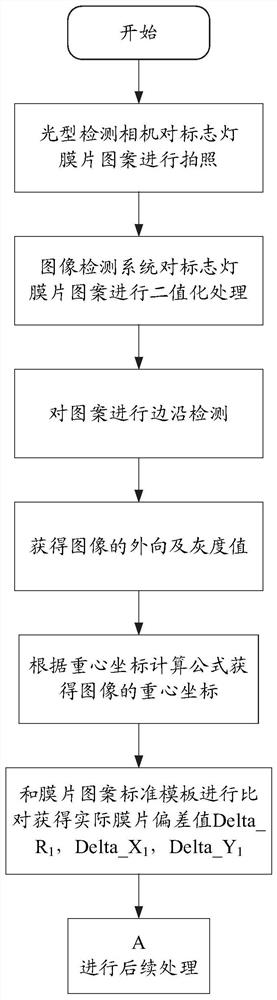

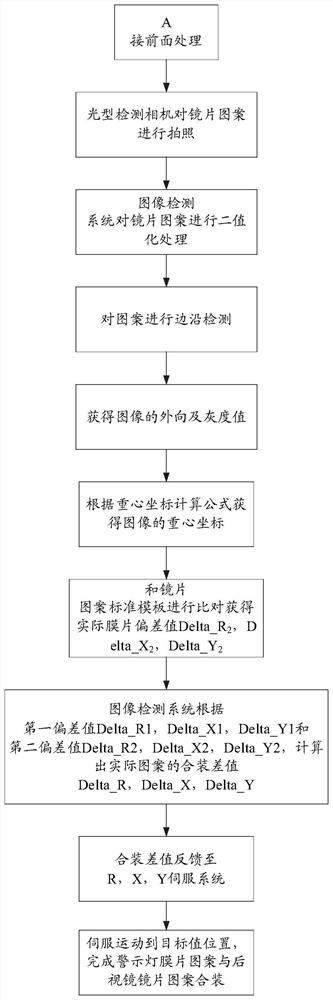

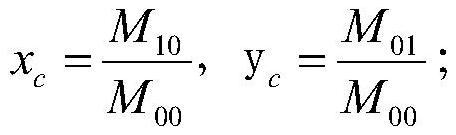

[0058] see figure 1 and figure 2 As shown, the image position deviation compensation processing method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com