Suspension type three-core whole-line sealing connector

A connector and suspension technology, which is applied in the field of suspension type three-core whole-line sealed connectors, can solve the problems of limited installation position and inability to meet the use requirements of connectors, and achieves the advantages of avoiding water ingress, realizing limit and ensuring sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

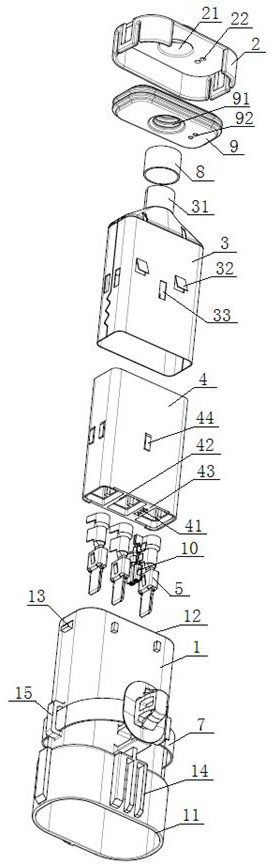

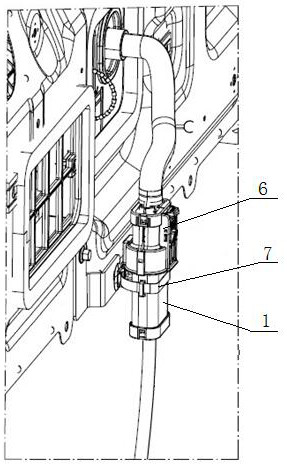

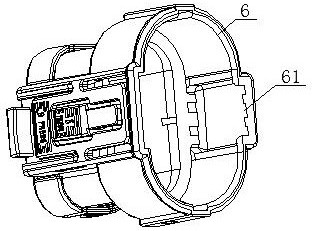

[0038] see Figure 1-Figure 3, a suspended three-core whole-line sealed connector, including a housing 1, a tail cover 2, a shielding layer 3 located inside the housing 1, a socket mounting plate 4, and a fixing tie 7, the housing 1, the tail cover 2 is made of engineering plastics, and the shell 1, the shielding layer 3, and the socket mounting plate 4 are all hollow structures with openings at both ends. The first open end 11 of the shell 1 is provided with a connector key bump 14, The connector key projections 14 match the grooves 61 provided on the inner wall of the suspension plug 6, and the second open end 12 of the housing 1 connects with the tail cap through a plurality of No. 1 projections 13 arranged along its outer circumference. 2 clamping, the outer wall of the middle part of the housing 1 is provided with limiting rings 15, the fixed strap 7 passes through the limiting ring 15 and is fixed with the bracket, and the bracket is fixed on the front wall of the driver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com