A municipal aluminum wire recycling and stripping device

A technology of stripping device and aluminum wire, applied in cable installation device, cable installation, equipment for dismantling/armored cable, etc. The effect of anti-card effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

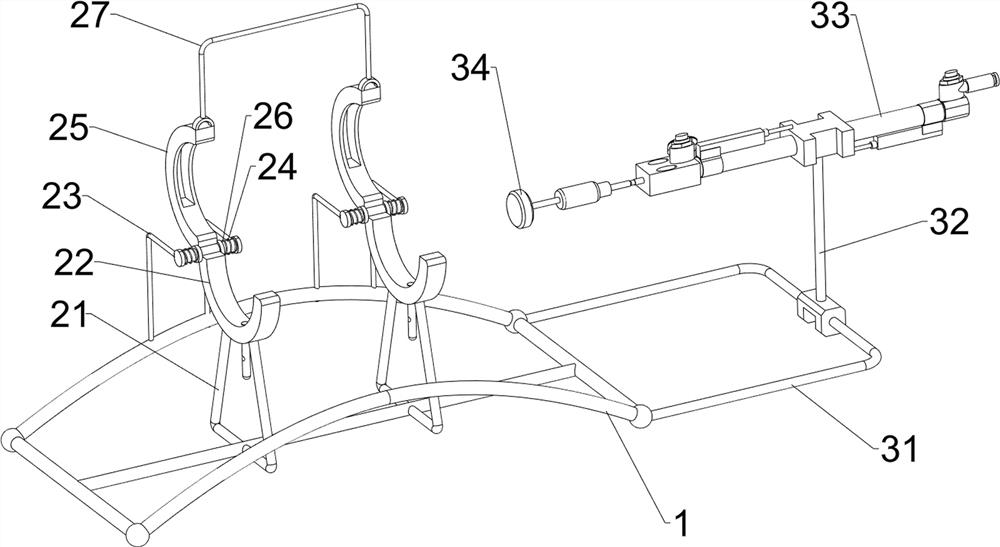

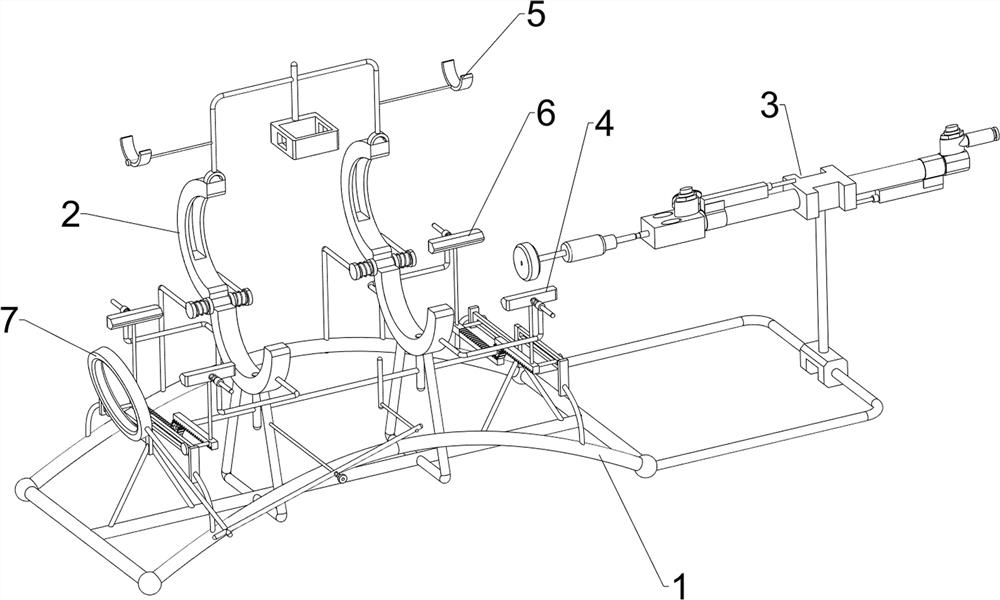

[0064] A municipal aluminum wire recovery and stripping device, such as figure 1 As shown, it includes a base 1 , a clamping mechanism 2 and a pushing mechanism 3 , the clamping mechanism 2 is arranged in the upper middle of the base 1 , and the pushing mechanism 3 is arranged on the right side of the base 1 .

[0065]When people want to strip aluminum wires, they can use this kind of aluminum wire recycling and stripping device for the municipal government. First, the user places the steel-cored aluminum stranded wire in the clamping mechanism 2, and the steel-cored aluminum stranded wire Carry out clamping, then start the pushing mechanism 3, the pushing mechanism 3 pushes the steel core in the steel-cored aluminum stranded wire, makes the steel core separate from the aluminum stranded wire, closes the pushing mechanism 3, and the above actions stop.

Embodiment 2

[0067] On the basis of Example 1, such as figure 2 As shown, the clamping mechanism 2 includes a first fixed frame 21, a lower clamp block 22, a second fixed frame 23, a first rotating shaft 24, an upper clamp block 25, a first spring 26 and a pull rod 27, and the upper middle part of the base 1 is provided with There are two first fixed mounts 21, and the tops of the two first fixed mounts 21 are provided with lower clamping blocks 22, and the middle part of the upper back side of the base 1 is evenly provided with four second fixed mounts 23, and the two second fixed mounts 23 on the same side The first rotating shaft 24 is connected between the front sides of the upper part of the frame 23, and the first rotating shaft 24 is connected with the lower clamping block 22. On each first rotating shaft 24, an upper clamping block 25 is rotatably provided. On each first rotating shaft 24 Both are wound with two first springs 26, and the opposite end of each first spring 26 is con...

Embodiment 3

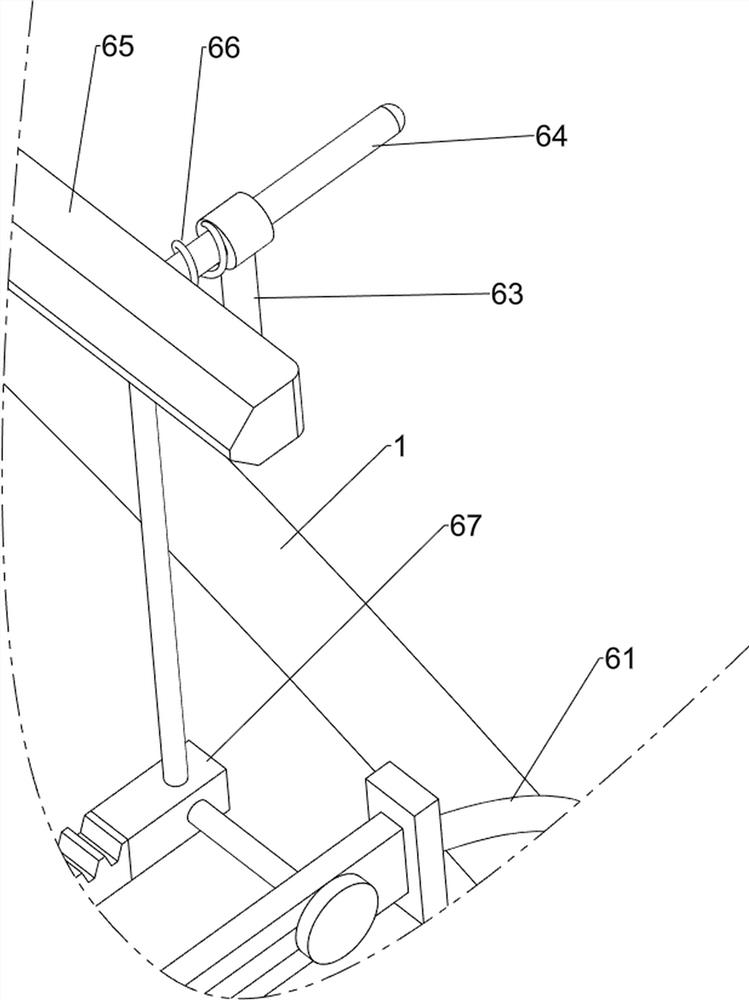

[0072] On the basis of Example 2, such as Figure 3-Figure 6 As shown, a cutting mechanism 4 is also included. The cutting mechanism 4 includes a first fixed bar 41, a first slide bar 42, a first cutting tool 43 and a second spring 44. Each lower clamping block 22 is provided with a The first fixed rod 41, each first fixed rod 41 top is all slidingly provided with the first slide bar 42, and each first slide bar 42 rear end is all provided with the first cutting tool 43, and each first slide bar 42 A second spring 44 is wound on each, the front end of the second spring 44 is connected to the first fixing rod 41 , and the rear end of the second spring 44 is connected to the first cutting tool 43 .

[0073] The user pushes the first slide bar 42 backwards, thereby driving the first cutting tool 43 to move backward, and the second spring 44 in the contracted state stretches backward, and the first cutting tool 43 performs the cutting on the steel ring on the ACSR. Cutting, to ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com