A medium-speed coal mill operation safety online monitoring and early warning system and method

A technology for safe operation and coal mills, applied in measuring devices, grain processing, instruments, etc., can solve the problems of large monitoring and operation volume, long time, difficult safety risk detection and early warning, etc., and achieves strong industrial application and application. , the effect of making up for market vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

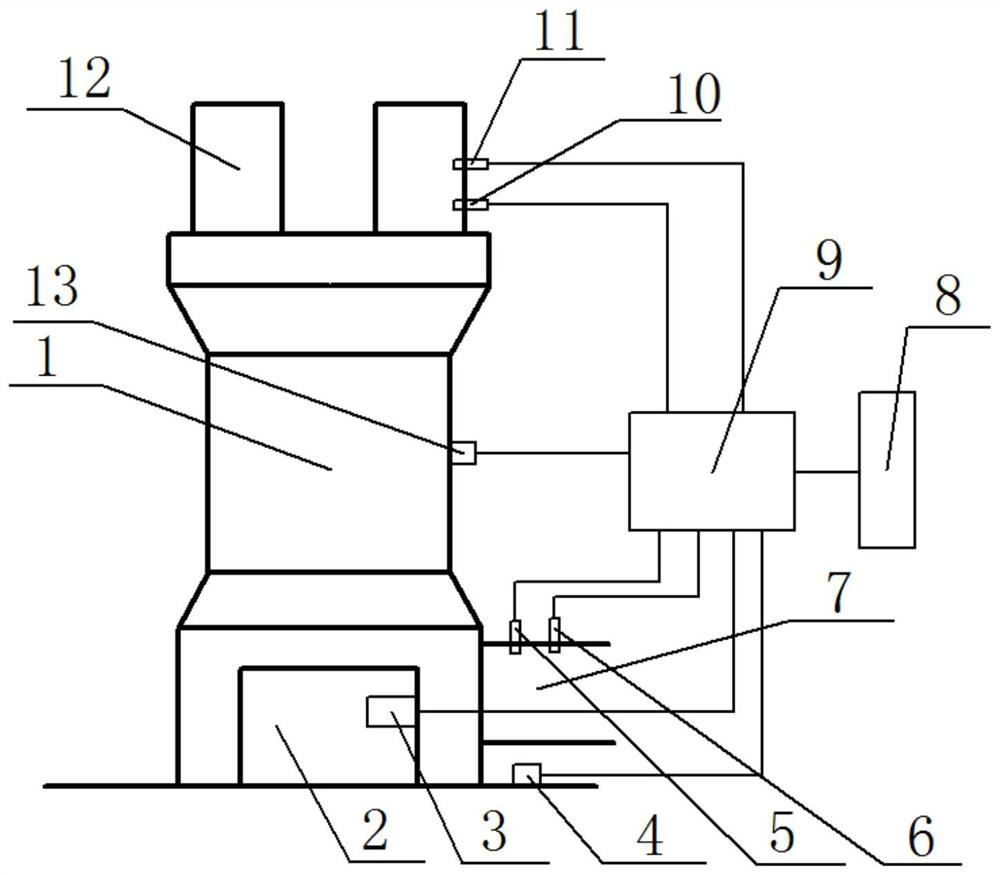

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0024] refer to figure 1, the medium-speed coal mill operation safety online monitoring and early warning system according to the present invention includes a pebble coal level sensor 3, a coal mill base vibration sensor 4, a coal mill inlet air pressure sensor 5, a coal mill inlet air temperature Sensor 6, coal mill body vibration sensor 13, coal mill outlet air pressure sensor 10, coal mill outlet temperature sensor 11 and data processing center 9; the stone coal level sensor 3 is located in the stone coal bunker 2, and the coal mill base The seat vibration sensor 4 is located on the coal mill base, the coal mill inlet air pressure sensor 5 and the coal mill inlet air temperature sensor 6 are located inside the primary air duct 7 at the coal mill inlet, and the coal mill body vibration sensor 13 is in the coal mill. On the machine 1, the coal mill outlet air pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com