Z-direction pressing laser welding tooling for battery tray

A battery tray and pressing device technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as affecting production efficiency, affecting product quality, and loose welding seams, and reducing the follow-up opening of the cylinder. , The action of the fixture is simplified, and the effect of the welding rhythm is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

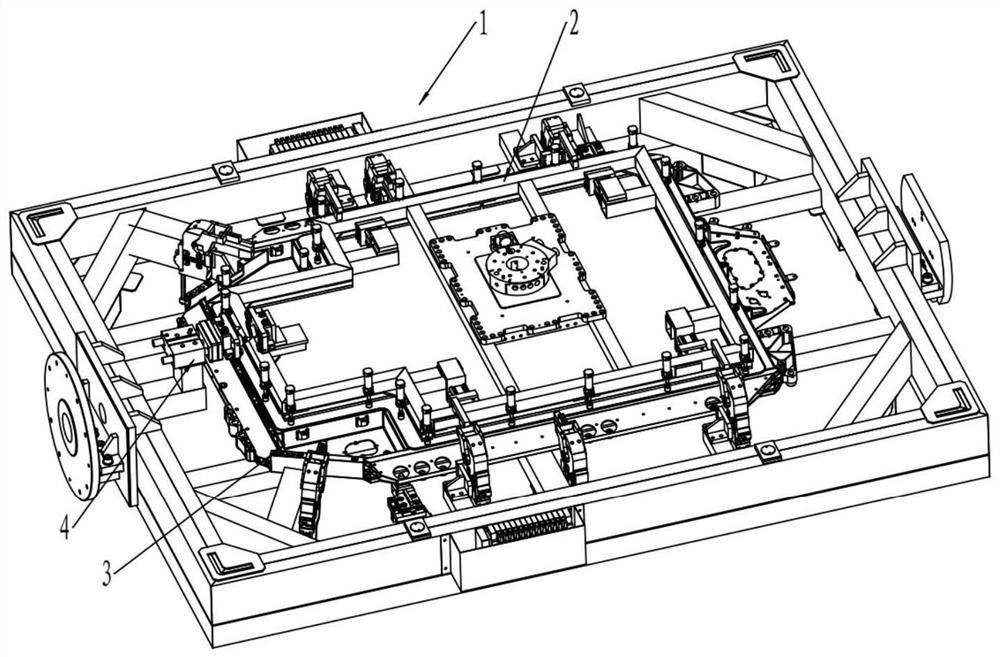

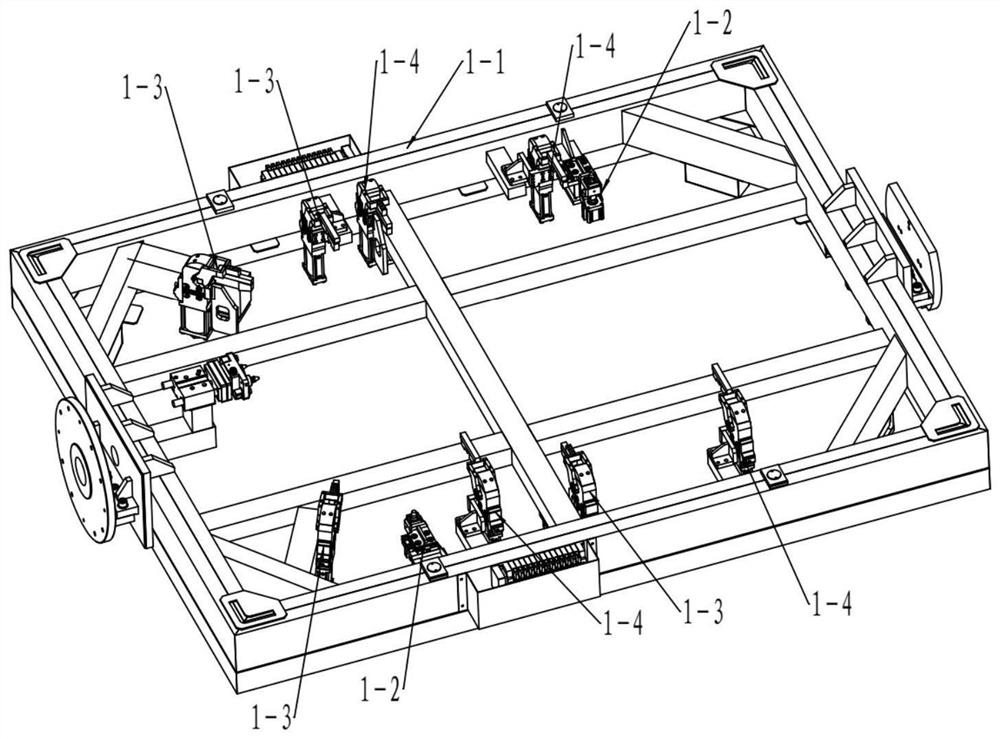

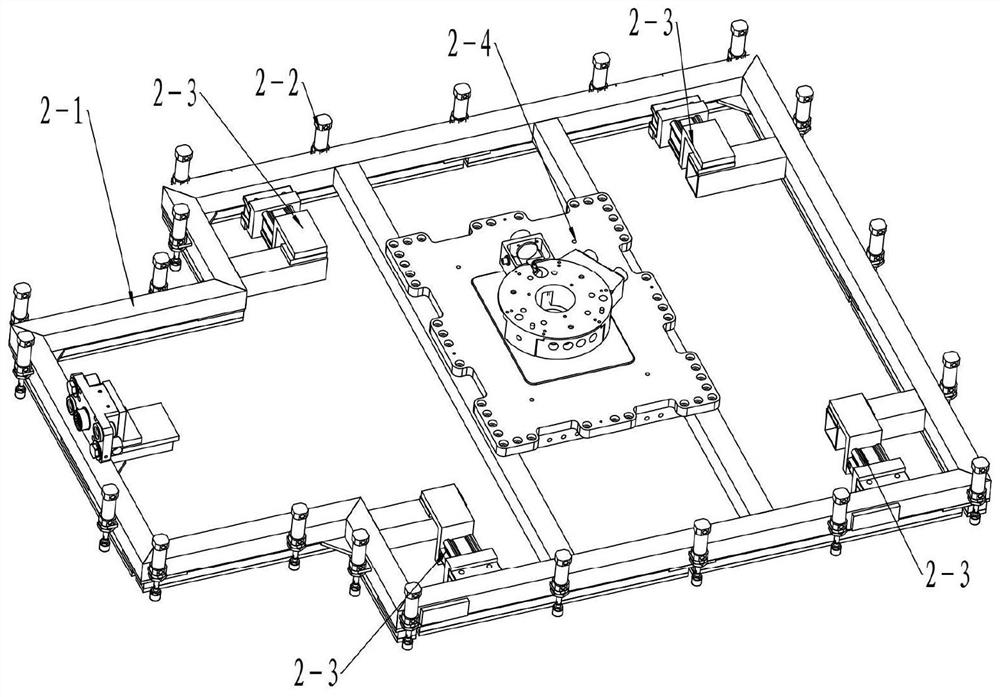

[0025] see figure 1 , the Z-direction compression laser welding tool for the battery tray of the present invention includes the main positioning and pressing device 1 for pressing and positioning the product parts 3 and the auxiliary pressing device 2 for automatically compensating and pressing the product parts, and the product parts 3 are compressed by the main positioning The device and the auxiliary pressing device are pressed together. The main positioning and pressing device plays the role of main positioning and Z-direction pressing of the battery tray product to be welded. The Z direction refers to the vertical direction. The function of the auxiliary pressing device is to During the welding process, when the welding torch passes through the follow-up pressing point and needs to open the pressing arm, it will automatically compensate and press the product, so as to keep the weld seam from having a gap of no more than 0.3mm.

[0026] see figure 1 , figure 2 , Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com