Oil pressing device for agricultural processing

An oil pressing device and agricultural processing technology, which is applied in the direction of manufacturing tools, fat oil/fat production, fat production, etc., can solve the problems of low efficiency of vegetable oilseed pressing, improve the effect of preheating, improve the effect and efficiency, and avoid solid-liquid bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

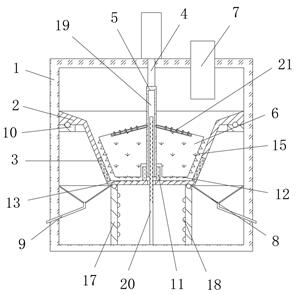

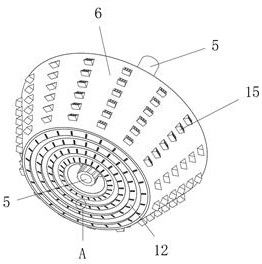

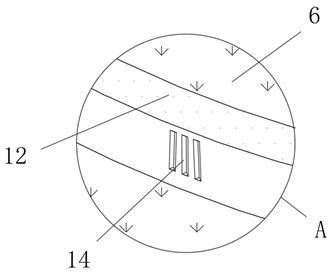

[0028] refer to Figure 1-4 , an oil pressing device for agricultural processing, comprising a processing cylinder 1, a cylinder 4 is fixed at the middle of the inner wall of the top of the processing cylinder 1, and a connecting rod 5 placed vertically is fixed at the bottom of the cylinder 4, and the bottom of the outer wall of the connecting rod 5 The oil pressing part 6 is fixed, and the circumferential inner wall of the processing cylinder 1 is fixed with a ring-shaped support seat 10, and the top of the support seat 10 is rotatably connected with an oil press seat 2 with a circular platform structure, and the middle position of the oil press seat 2 is provided with The bottom of the outer wall of the oil press seat 2 is provided with a ring-shaped filter screen plate 3, and the middle position of the bottom inner wall of the oil press seat 2 is fixed with a connecting cylinder 11, and the middle of the bottom of the oil press unit 6 The location is provided with an accom...

Embodiment 2

[0034] refer to Figure 1-6 , an oil pressing device for agricultural processing, a support cylinder 17 is fixed at the middle of the inner wall of the bottom of the processing cylinder 1, and a rubber pad with a ring structure is fixed on the inner and outer sides of the outer wall of the top of the support cylinder 17, and the outer wall of the top of the support cylinder 17 The middle position is rollingly connected with a plurality of second balls, and the position corresponding to the second ball on the outer wall of the bottom of the oil press seat 2 is provided with a ring-shaped second chute, and the inner wall of the support cylinder 17 is fixed with a heating coil 18. There is a connecting chamber 19 with an open bottom end inside the inner wall of the oil press seat 2, and the position corresponding to the connecting chamber 19 is provided with a perforation, and the middle position of the inner wall of the bottom of the processing cylinder 1 is fixed with a drainage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com