A kind of multi-size gradient filler modified solvent-free heavy-duty anti-corrosion coating and preparation method thereof

A gradient type, heavy-duty anti-corrosion technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as insufficient corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing a multi-size gradient filler-modified solvent-free heavy-duty anti-corrosion coating comprises the following steps:

[0030] (1) Preparation of modified graphene: mixing ethanol and water according to a volume ratio of 3:1, mixing the mixed solution with graphene oxide, stirring the mixture and ultrasonically dispersing to obtain a homogeneous graphene oxide suspension, Add γ-aminopropyltriethoxysilane-modified graphene oxide to it according to the stoichiometric ratio, stir and condense and reflux at a constant temperature in an oil bath at 70°C for 6h-8h to make it react fully, and then vacuum pump filtered, washed with ethanol / water mixed solution, and subjected to critical freeze-drying to obtain amino-modified graphene;

[0031] (2) Ingredients: take film-forming material, filler and auxiliary agent respectively in proportion;

[0032] (3) Grinding: Add fillers and additives to the film-forming material, stir with a mixer at high speed for a...

Embodiment 1

[0050] (1) Preparation of modified graphene: mixing ethanol and water according to a volume ratio of 3:1, mixing the mixed solution with graphene oxide, stirring the mixture and ultrasonically dispersing to obtain a homogeneous graphene oxide suspension, According to the stoichiometric ratio, graphene oxide modified by γ-aminopropyltriethoxysilane was added thereto, stirred at a constant temperature in an oil bath at 70°C, condensed and refluxed for 6 hours to make the reaction fully, and then vacuum suctioned, Washing with ethanol / water mixed solution and performing critical freeze-drying to obtain amino-modified graphene;

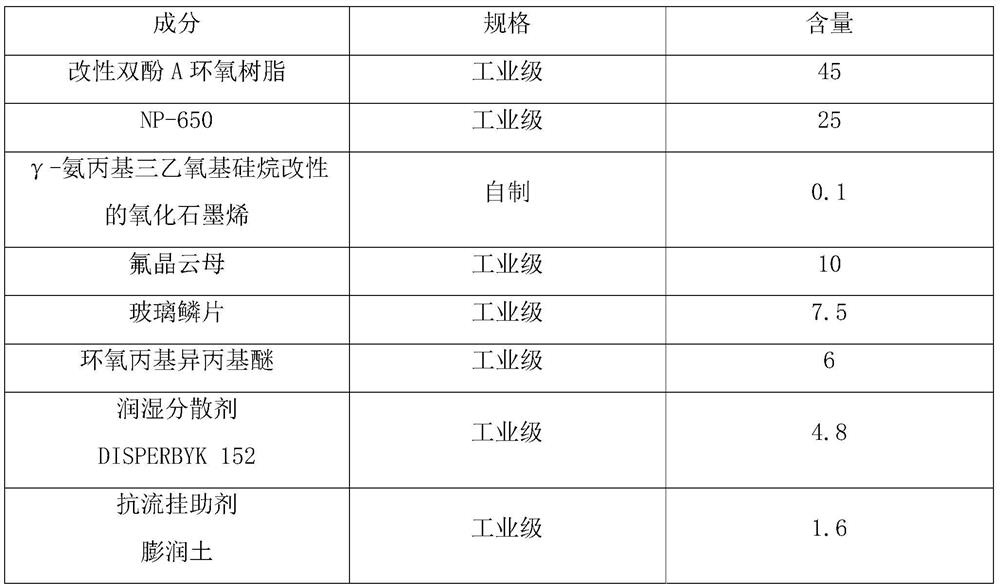

[0051] (2) Ingredients: Weigh the film-forming materials, fillers and additives in proportion as follows:

[0052]

[0053] (3) Grinding: Add fillers and additives to the film-forming material, stir with a mixer at high speed for 10 minutes, and then put it into a sand mill to grind until the output viscosity is 15000-19000mPa·s to obtain a multi-size ...

Embodiment 2

[0060] (1) Preparation of modified graphene: mixing ethanol and water according to a volume ratio of 3:1, mixing the mixed solution with graphene oxide, stirring the mixture and ultrasonically dispersing to obtain a homogeneous graphene oxide suspension, According to the stoichiometric ratio, graphene oxide modified by γ-aminopropyltriethoxysilane was added thereto, stirred at a constant temperature in an oil bath at 70°C, condensed and refluxed for 8 hours to make the reaction fully, and then vacuum suctioned, Washing with ethanol / water mixed solution and performing critical freeze-drying to obtain amino-modified graphene;

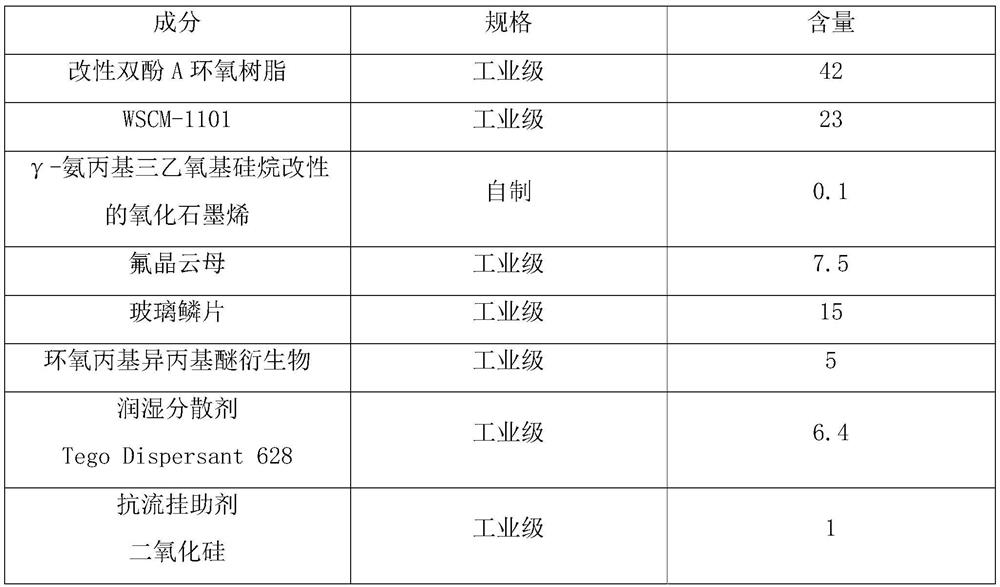

[0061] (2) Batching: Take film-forming material, filler and auxiliary agent respectively in proportion as follows:

[0062]

[0063] (3) Grinding: Add fillers and additives to the film-forming material, stir with a mixer at high speed for 10 minutes, and then put it into a sand mill to grind until the output viscosity is 15000-19000mPa·s to obtain a mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com