Large-span trapezoidal space steel pipe truss concrete floor structure

A steel pipe truss, large-span technology, applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve the problem that lightweight roofs cannot guarantee the bearing capacity and stiffness requirements, and it is difficult to meet the mechanical properties, economical and economical. It can achieve the effect of rich body, easy pipeline crossing, and small amount of structural steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

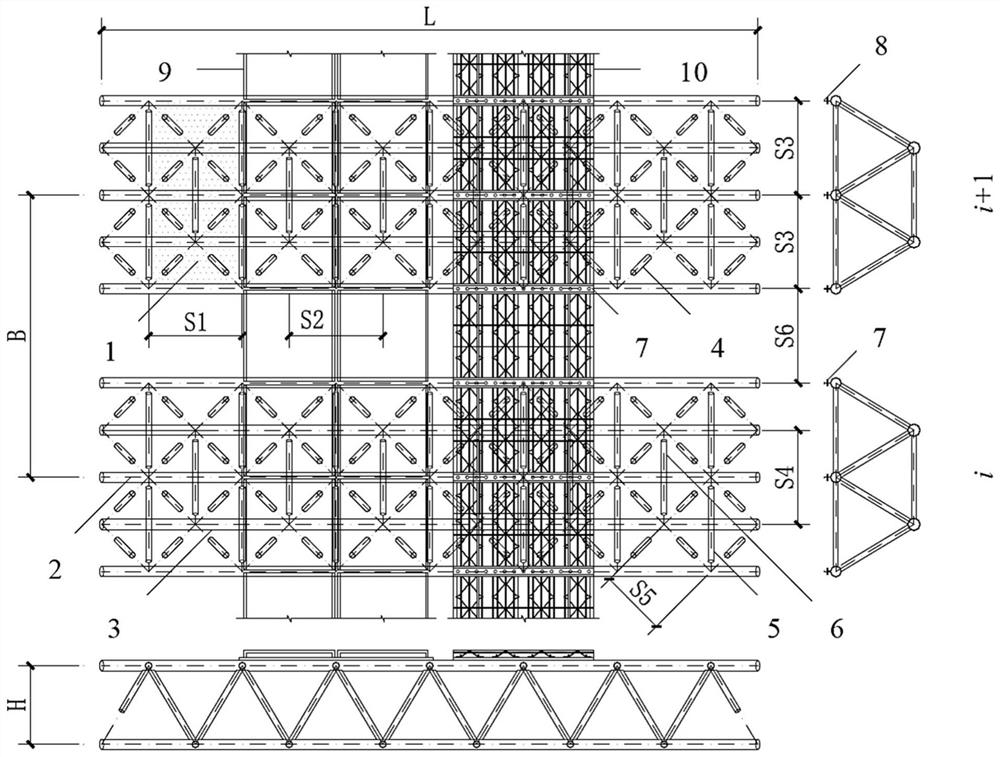

[0024] see figure 1 , the present invention includes a large-span trapezoidal space steel pipe truss and a concrete floor, and the concrete floor directly bearing the floor load is arranged on the T-shaped support of the three-tube upper chord 2 of the large-span trapezoidal space steel pipe truss; the large-span trapezoidal space steel pipe truss The basic unit 1 is an internode, and each internode is composed of three tube upper chords 2, two tube lower chords 3, quadrangular pyramid diagonal rods 4, upper chord horizontal rods 5, and lower chord horizontal rods 6; The cross-sectional shape is an inverted trapezoid arranged in a triangle; the large span is spliced by several basic units of the trapezoidal space steel pipe truss; the three-tube upper chord 2 and the two-tube lower chord 3 of the large-span trapezoidal space steel pipe truss are main pipes;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com