Multifunctional filter for hydraulic system and assembly method of multifunctional filter

A hydraulic system and multi-functional technology, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, fixing devices, etc., can solve the problem of inconvenient installation of the top cover or base of the filter, so as to increase the connection stability, The effect of reducing impact force and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

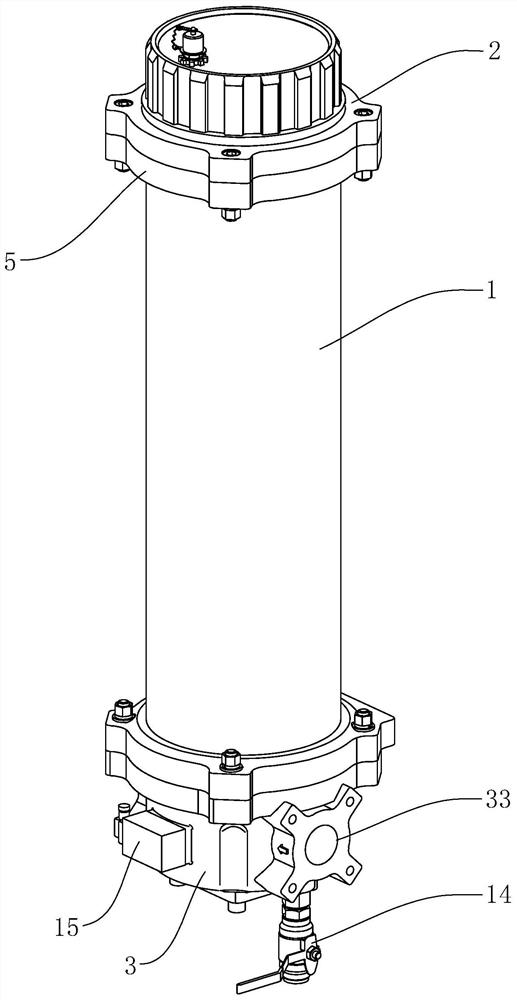

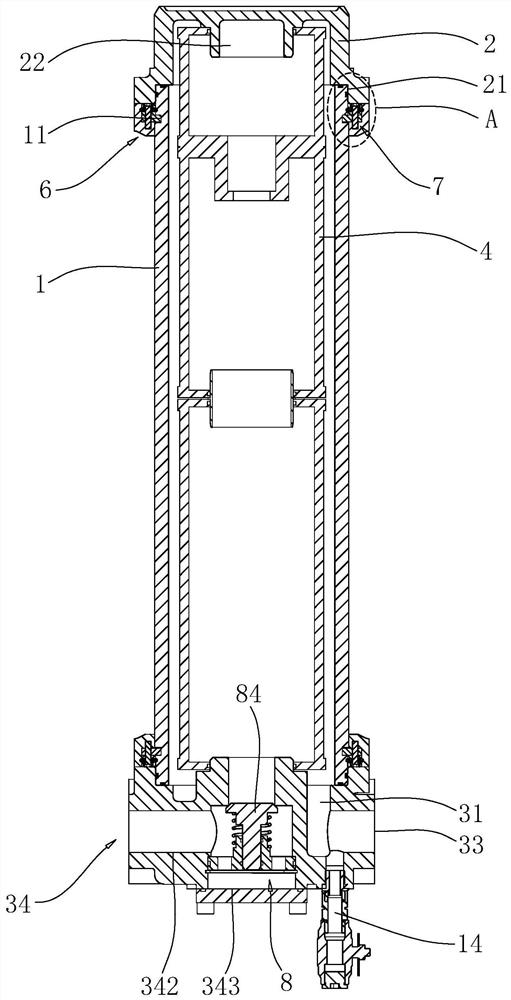

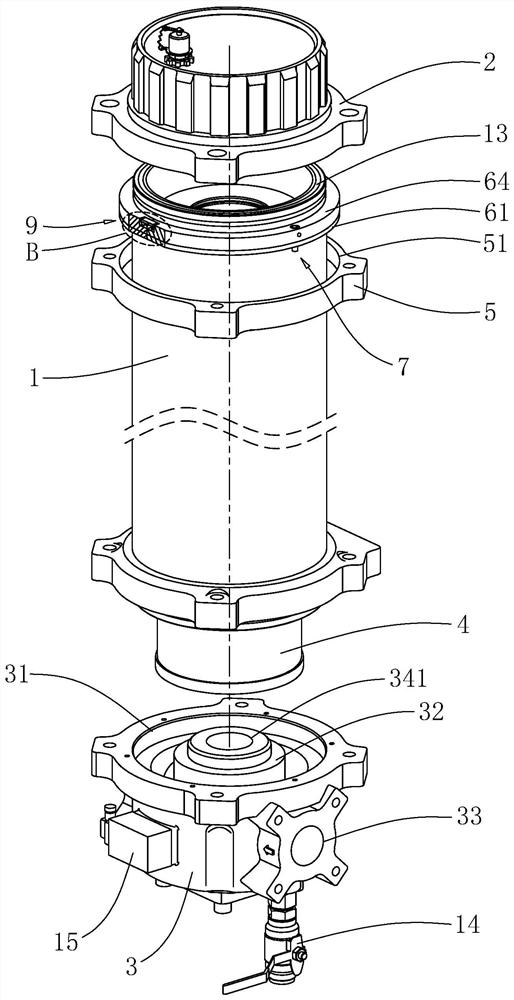

[0045] refer to figure 1 and figure 2 , the multifunctional filter includes a filter cartridge 1, a base 3, a top cover 2 and a filter element 4, and the filter cartridge 1 is provided with two connection seats 5 along the length direction, and the two connection seats 5 are away from each other and close to the filter cartridge 1 One side is provided with an annular fixing groove 51 . Both ends of the filter cartridge 1 along the length direction are provided with an annular groove 11 , and a stopper 6 is inserted into each of the two annular grooves 11 .

[0046] refer to figure 2 and image 3 , the limiting member 6 includes a semicircular limiting plate 61 inserted into the ring groove 11, and two limiting plates 61 are provided along the circumferential direction of the filter cartridge 1, and the end faces of the two limiting plates 61 are in conflict . The limit plate 61 is provided with an integrally formed fixed block 64 on the side away from the bottom wall o...

Embodiment 2

[0066] refer to Figure 8 The difference between this embodiment and Embodiment 1 is that the limiting member 6 includes a limiting ring 62 , and a fixing block 64 is provided on the inner wall of the limiting ring 62 . Both ends of the filter cartridge 1 along the length direction are provided with a pair of limiting grooves 12 , and the same pair of limiting grooves 12 are arranged along the circumferential direction of the filter cartridge 1 . The limiting groove 12 includes a vertical groove 121 provided on the end face of the filter cartridge 1 and an arc groove 122 communicating with the vertical groove 121. The vertical groove 121 is arranged along the axial direction of the filter cartridge 1, and the arc groove 122 is arranged along the axis of the filter cartridge 1. Arc direction setting.

[0067] refer to Figure 8 In the process of installing the limit ring 62, the operator aligns the limit block 63 with the notch of the vertical groove 121, and pushes the limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com