Bearing structure

A technology for bearings and mandrels, applied in bearings, bearing components, shafts and bearings, etc., can solve problems such as reduced bearing service life, increased radial clearance, and rolling body wear, so as to prolong service life and slow down radial Effects of increased clearance and reduced sound pressure level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

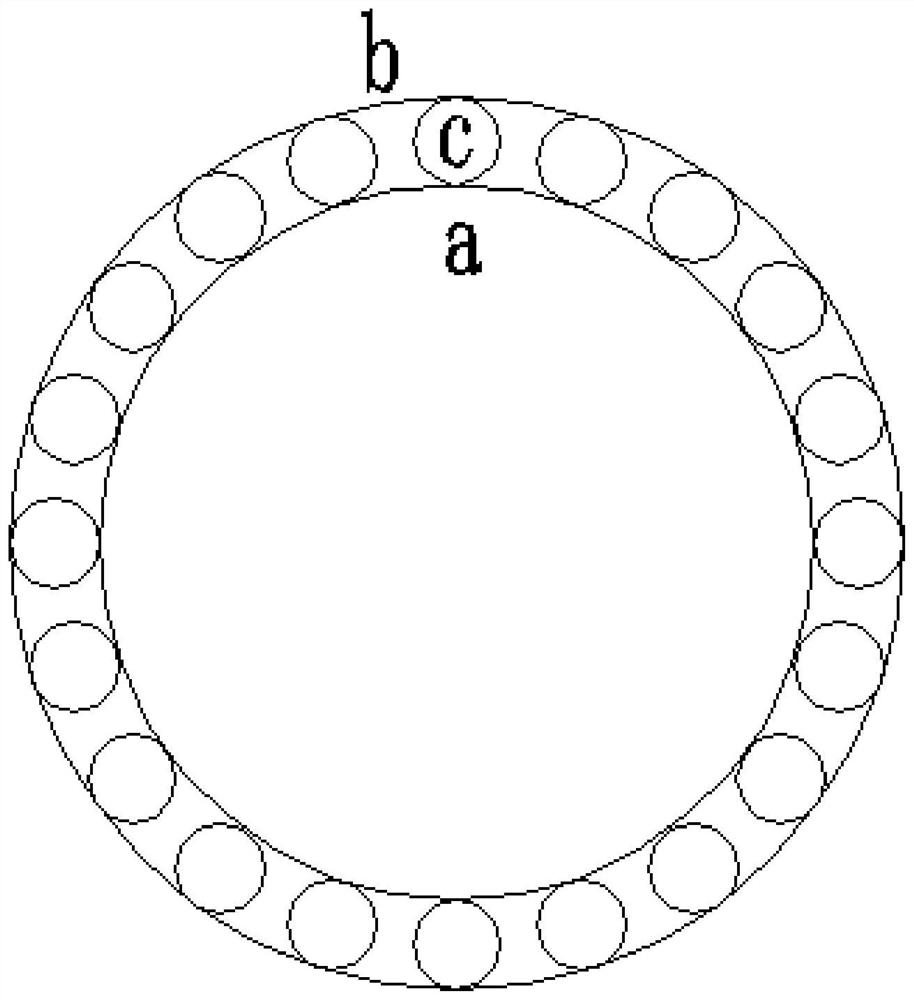

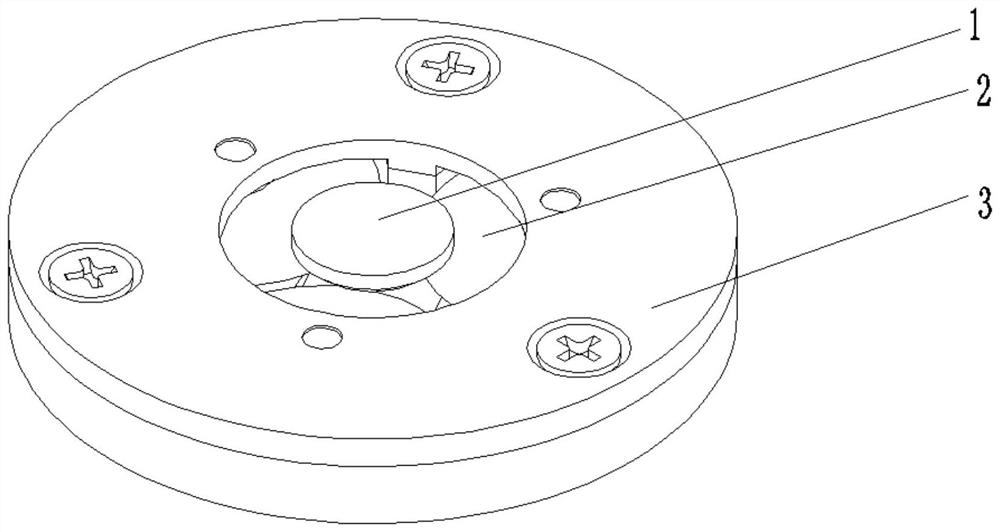

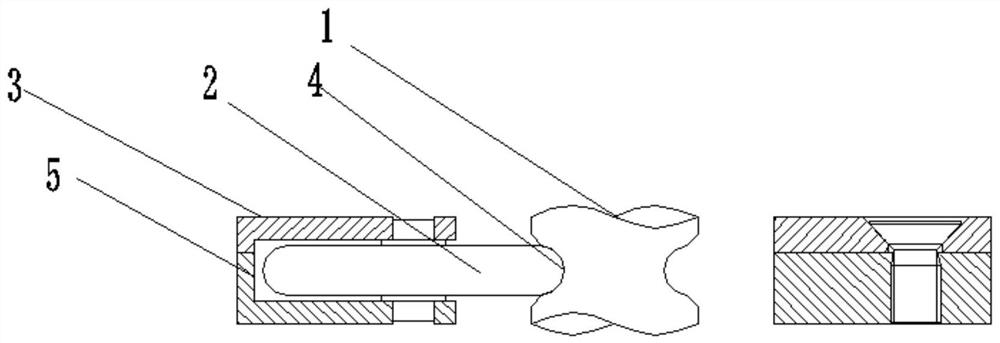

[0034] refer to Figure 2-3 As shown, an embodiment of the bearing structure of the present invention includes a mandrel 1, a rolling element 2 and a cage 3, and the outer wall of the mandrel 1 and the inner wall of the cage 3 form an inner race 4 and an outer race 5 respectively. , the rolling body 2 is sandwiched between the inner rolling ring 4 and the outer rolling ring 5, the rolling body 2 is a disc-shaped structure, the rolling body 2 includes a central axis, and the rolling body takes the central axis as an axis The center rotates, and the diameter of the shaft hole of the mandrel 1 is smaller than the diameter of the rolling body 2 .

[0035] In this embodiment, the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com