A real-time online measurement method of drilling cuttings weight

A measurement method and technology of drilling cuttings, applied in the field of petroleum drilling, can solve the problems of discontinuous measurement and inability to measure, and achieve the effect of strong site adaptability, small changes and economical modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

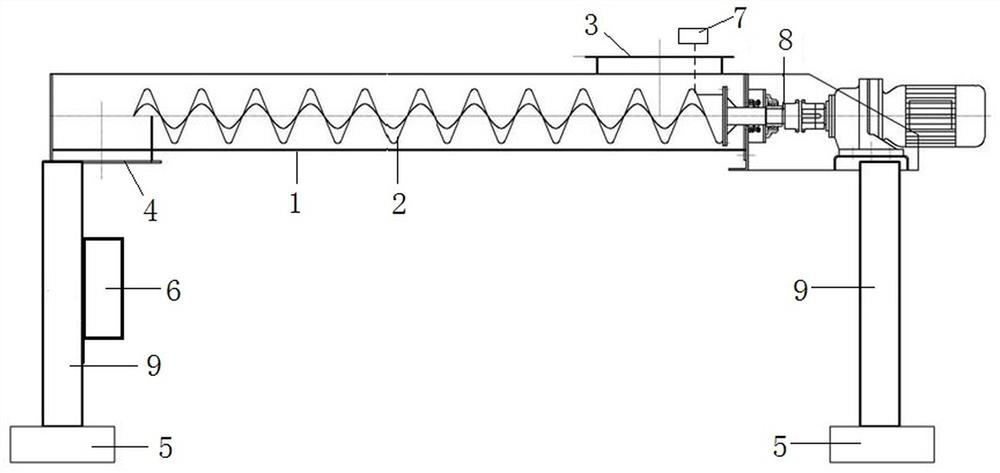

[0027] The invention discloses a real-time online measurement method for the weight of drilling cuttings, such as figure 1 As shown, it includes a processor, a screw conveyor 1, a longitudinal vibration sensor 6 for obtaining the vibration acceleration of the screw conveyor 1, a weight sensor 5 for obtaining the weight of the screw conveyor 1, and a sensor for obtaining the number of rotations of the screw shaft 2 The detector; wherein, the screw conveyor 1 is provided with a feed port 3 and a discharge port 4, and the feed port 3 and the discharge port 4 are respectively arranged at the upper and lower parts of the two ends of the screw shaft 2 for the feeding of cuttings. material and discharge; the screw conveyor 1 is respectively fixed on two bases (not shown in the figure) by two support columns 9, the number of weight sensors 5 is two, and the support columns 9 respectively arranged on the two bases Below; the weight of the screw conveyor 1 is the sum of two weight senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com