Propylene synthesis reactor

A technology for synthesizing reactors and propylene, which is applied in the field of reactors, can solve the problems of inconvenient dispersing and adding raw materials, and achieve the effect of facilitating dispersing and adding raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

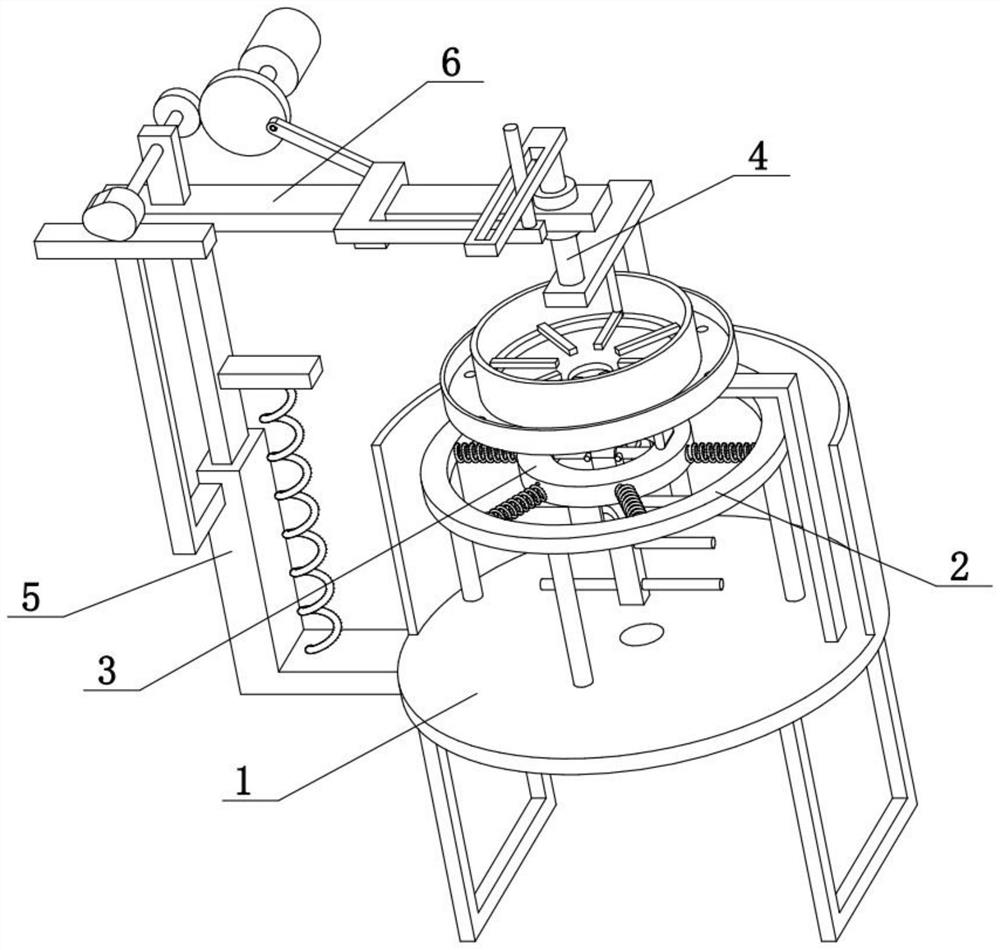

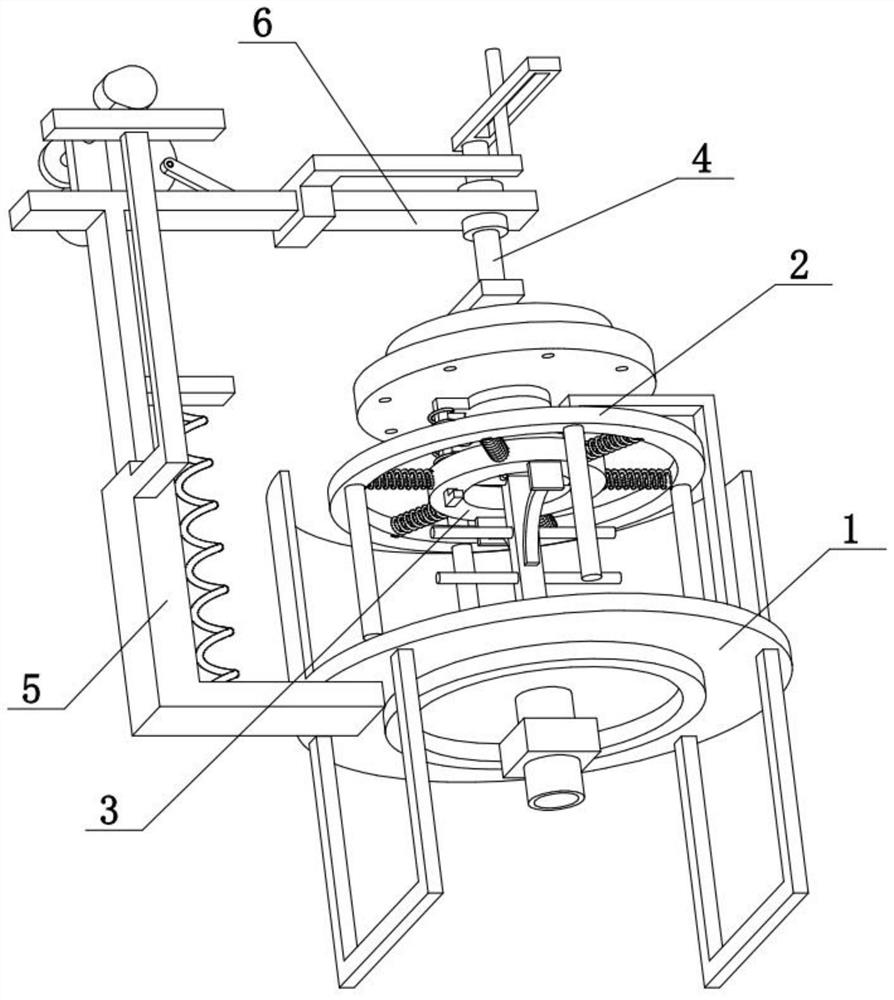

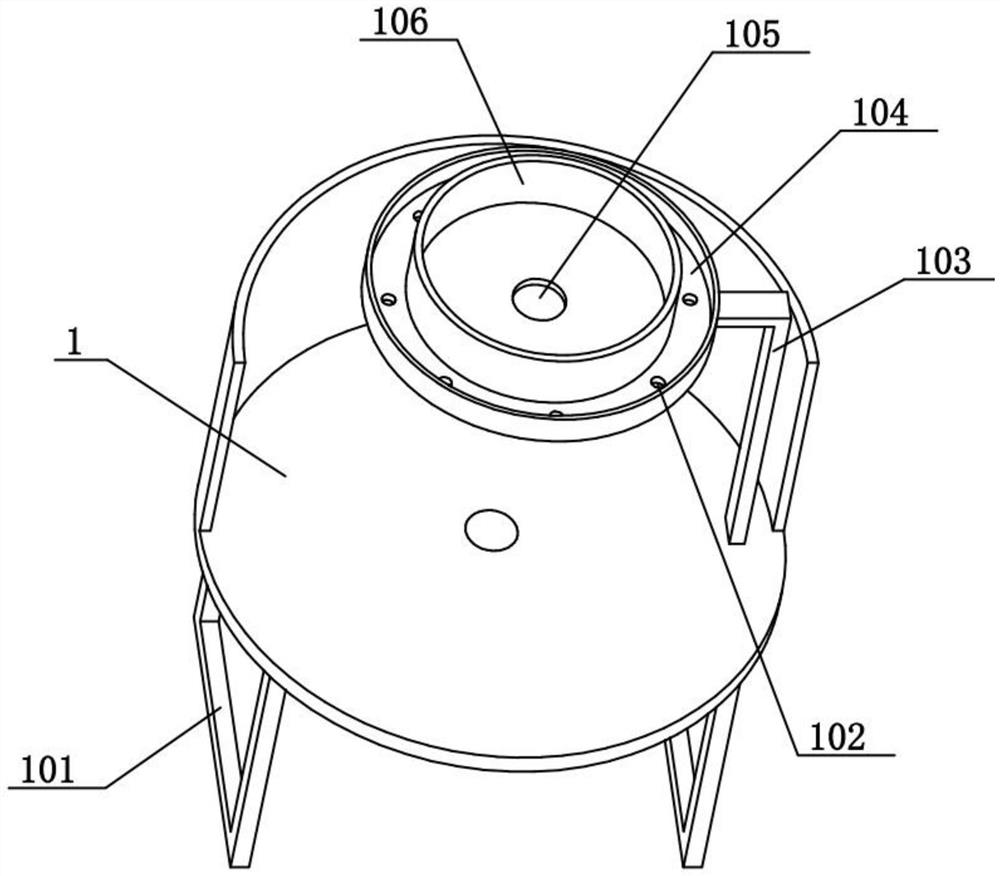

[0029] Combine below Figure 1-9 To illustrate this embodiment, the present invention relates to a reactor, more specifically a propylene synthesis reactor, comprising a reaction box 1, a bracket 101, a circular through hole 102, an L-shaped rod 103, a ring box 104, and a leak hole 105, round box 106 and heating wire 108, the present invention can be convenient to disperse and add raw material.

[0030] The left and right ends of the lower side of the reaction box 1 are fixedly connected with brackets 101, the lower side of the reaction box 1 is provided with a heating wire 108, and the lower end of the L-shaped rod 103 is fixedly connected to the edge position of the inner bottom surface of the reaction box 1. The center of the box 106 is provided with a leakage hole 105, and the outer periphery of the circular box 106 is provided with a ring box 104. The ring box 104 is provided with a plurality of circular through holes 102 in a ring shape, and the ring box 104 and the roun...

specific Embodiment approach 2

[0032] Combine below Figure 1-9 To illustrate this embodiment, the propylene synthesis reactor further includes a discharge pipe 109 , the discharge pipe 109 is provided at the lower part of the reaction box 1 , and a solenoid valve is provided on the discharge pipe 109 . The discharge pipe 109 is used for discharging, and the solenoid valve is used to control the switch of the discharge pipe 109 .

specific Embodiment approach 3

[0034] Combine below Figure 1-9To illustrate this embodiment, the propylene synthesis reactor also includes an outer ring 2, a fixed rod 201, a tension spring 1202, an inner ring 3, a horizontal shaft 301, an arc spring rod 305, a swing rod 306, and a stirring rod 307. The outer ring The lower side of the 2 is evenly distributed with a plurality of vertically arranged fixed rods 201, and the inner ring of the outer ring 2 is evenly connected with a plurality of tension springs I202, and the inner ends of the plurality of tension springs I202 are fixedly connected to the inner ring 3 On the outer peripheral surface of the inner ring 3, a horizontal shaft 301 is arranged on the inner ring, and the upper part of the swing rod 306 is rotatably connected to the middle part of the horizontal shaft 301. On the swing rod 306, a plurality of stirring rods 307 are uniformly distributed from top to bottom, and the inner ring 3. The front and rear ends of the lower side are fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com