Fluorescent lamp tube cleaning device for stone factory

A technology for a fluorescent tube and a cleaning device, which is applied to a cleaning method using tools, a cleaning method using gas flow, and cleaning hollow objects, etc., can solve problems that affect the heat dissipation of the lamp tube, have a lot of dust, and do not have a cleaning device for the fluorescent tube, etc. , to avoid external power, increase cleaning effect, and achieve the effect of power resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

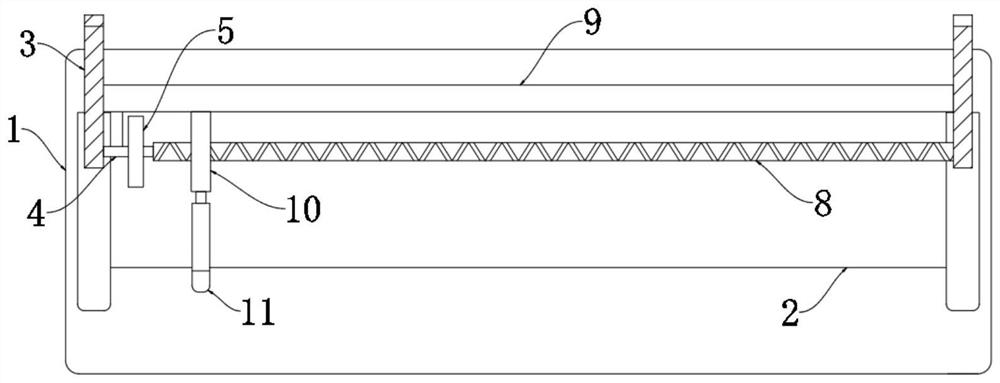

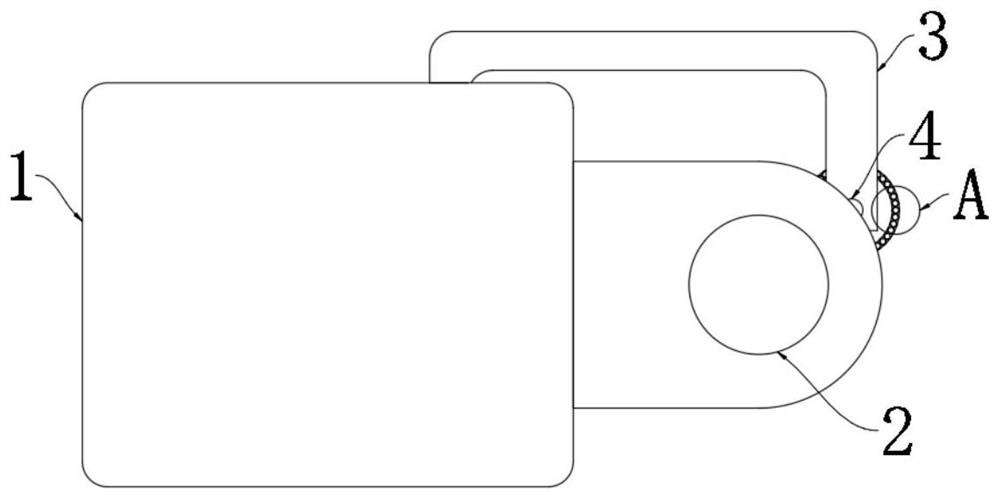

[0033] refer to Figure 1-4 , a fluorescent tube cleaning device for a stone factory, comprising a lamp holder 1, the lamp holder 1 is provided with a lamp body 2;

[0034] A pair of mounting frames 3 are fixedly connected to the lamp holder 1, a rotating shaft 4 is rotatably connected between the pair of mounting frames 3, and a fixed column 9 is fixedly connected between the pair of mounting frames 3;

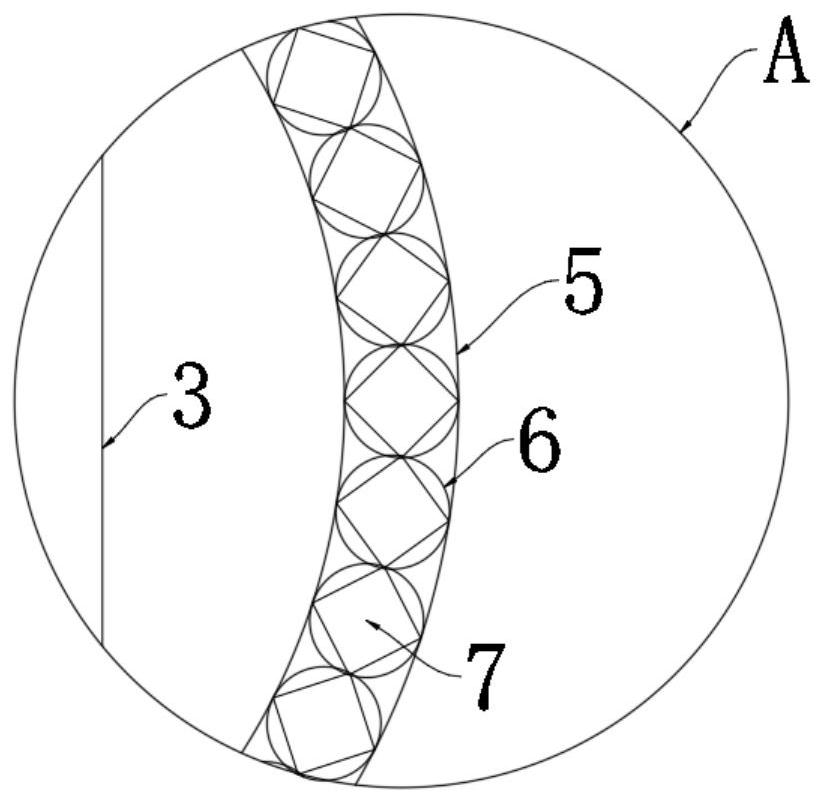

[0035] The outer wall of the rotating shaft 4 is fixedly connected with a hollow ring 5 through a plurality of connecting rods. The hollow ring 5 is provided with a plurality of heat-expandable balls 6 in contact with each other, and a plurality of heat-expandable balls 6 are embedded with counterweights 7. By setting the thermal expansion ball 6, the rotating shaft 4, the hollow ring 5, etc., the heat generated when the lamp body 2 is illuminated is converted into the power for the rotating shaft 4 to avoid external power and realize the saving of power resources. Thermal e...

Embodiment 2

[0041] refer to Figure 5-6 , a fluorescent tube cleaning device for a stone factory, the fixed column 9 is provided with an air intake cavity 13, and the air intake cavity 13 is sealed and slidably connected with a piston 14;

[0042] The right side wall of the piston 14 is fixedly connected with a magnet 15 slidably connected to the inner side wall of the air intake chamber 13, and a semicircular magnetic ring 16 is slidably connected to the outer side wall of the fixed column 9, and the semicircular magnetic ring 16 is fixedly connected with the lead screw nut 10;

[0043] The air intake end of the air intake chamber 13 communicates with the outside world, and a check valve that only allows air to enter the air intake chamber 13 from the outside world is provided at the communication point;

[0044] The cleaning ring 11 is provided with an annular chamber 17, and the side wall of the annular chamber 17 is provided with a plurality of air injection ports 18 penetrating throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com