Water transfer printing equipment for wooden stair stand column

A technology of water transfer printing and column, which is applied in transfer printing, rotary printing machine, printing, etc., can solve the problems of insufficient visual effect, high cost of materials, high labor cost, etc., to save time for manual blanking and collection, and improve Transport efficiency, realize the effect of automatic transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

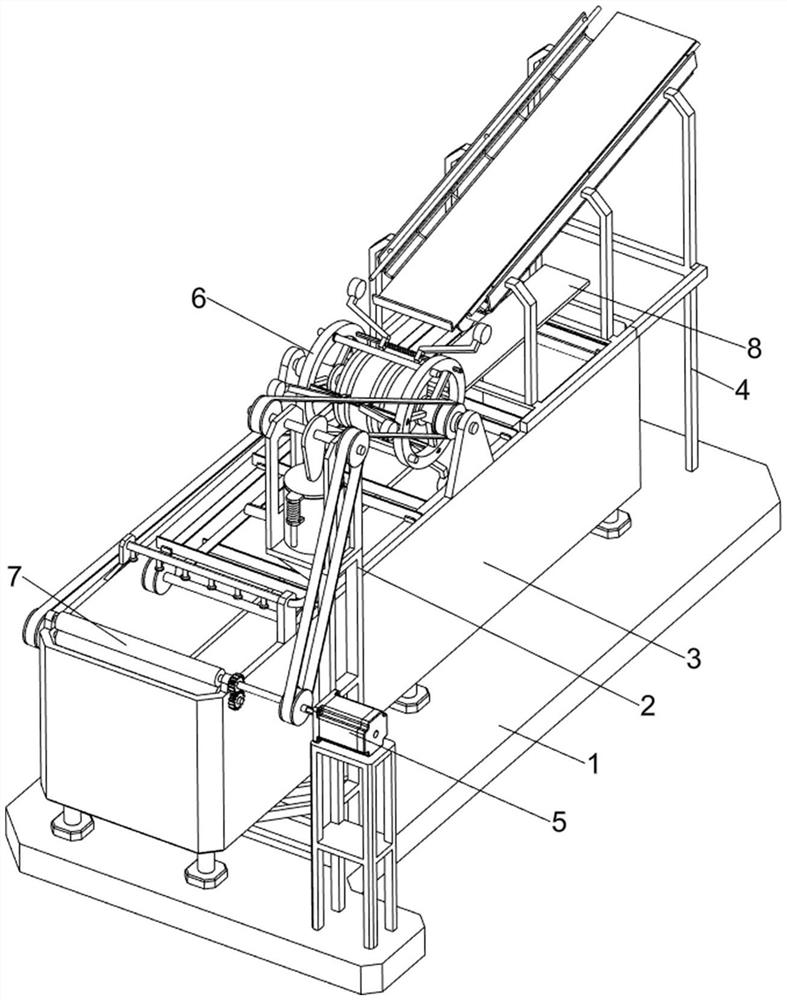

[0074] A water transfer printing equipment for wood stair column such as figure 1 As shown, it includes a base plate 1, a bracket 2, a flow film device 3 and a feeding mechanism 4, a support 2 is provided on the right front side of the base plate 1, a flow film device 3 is provided on the base plate 1, and a flow film device 3 is provided between the base plate 1 and the flow film device 3. There are feeding mechanism 4.

[0075] When people need to carry out water transfer printing on the material, after filling the flow film device 3 with water, place the water transfer printing pigment on the water surface, then place the material in the feeding mechanism 4, manually operate the flow film device 3, When the material falls from the feeding mechanism 4 onto the water transfer printing pigment, the water transfer printing operation is performed on the material. After the water transfer printing is completed, the operation of the flow film device 3 is manually stopped, and the ...

Embodiment 2

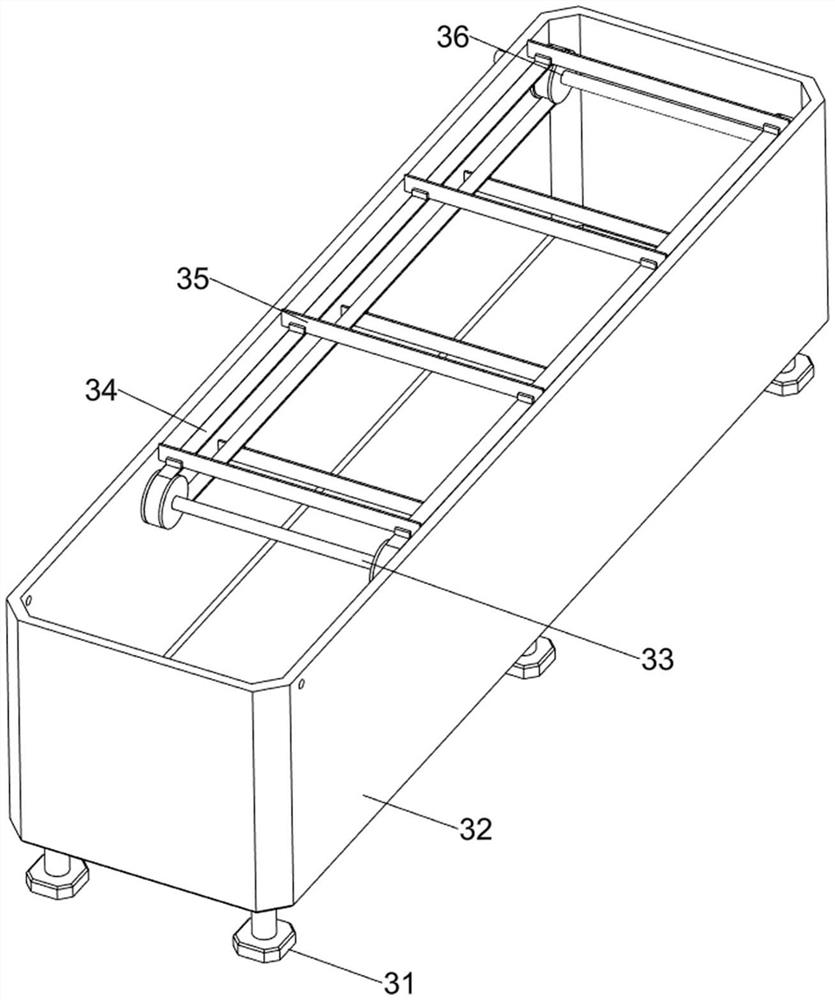

[0077] On the basis of Example 1, such as figure 2 As shown, the film flow device 3 includes a stand 31, a water tank 32, a first drive shaft 33, a belt set 34 with a plate, a partition plate 35 and a second drive shaft 36, and the bottom plate 1 is provided with a plurality of stand 31, A water tank 32 is arranged between the stand legs 31. The front portion of the water tank 32 is rotatably connected with a first transmission shaft 33, and the rear portion of the water tank 32 is rotatably connected with a second transmission shaft 36. Between the second transmission shaft 36 and the first transmission shaft 33 Attached plate belt set 34 is connected between them, and a plurality of partition plates 35 are evenly arranged on the attached plate belt set 34 .

[0078] Fill the water tank 32 with water, then manually operate the ink on the water, and manually rotate the first transmission shaft 33 to make the attached plate belt set 34 and the partition plate 35 move to separa...

Embodiment 3

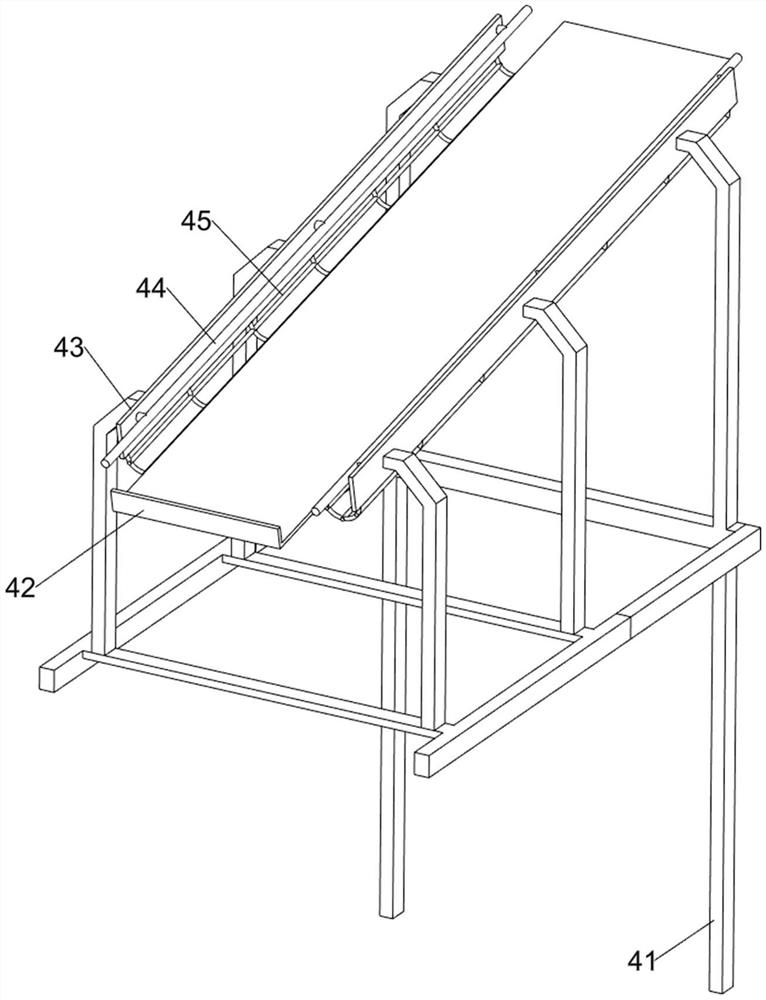

[0080] On the basis of Example 2, such as Figure 3 to Figure 8 As shown, the feed mechanism 4 includes a feed frame 41, a feed plate 42, a side baffle plate 43, a guide rod 44 and a special-shaped frame 45, and the bottom plate 1 rear portion is provided with a feed frame 41, and the feed frame 41 top, left and right sides The sides are all provided with side baffles 43, and the side baffles 43 are all provided with guide bars 44, and the side baffles 43 are all connected with special-shaped frames 45, and are connected with feed plates 42 between the special-shaped frames 45.

[0081] Before the material is transferred, the material is placed on the feed plate 42, and the material slides down to the front of the feed plate 42 through the guiding action of the guide rod 44, waiting for feeding.

[0082] Also comprise activation device 5, activation device 5 comprises motor frame 51, slow motor 52, the 3rd transmission shaft 53, the first transmission belt set 54, the 4th tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com