Connecting rod type grain shoveling and bagging machine

A grain bagging machine, connecting rod type technology, applied in the field of connecting rod type shoveling grain bagging machine, can solve the problems of large movement range, time-consuming and laborious, complex structure, etc., and achieve safe and convenient use, convenient use, and simple device operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

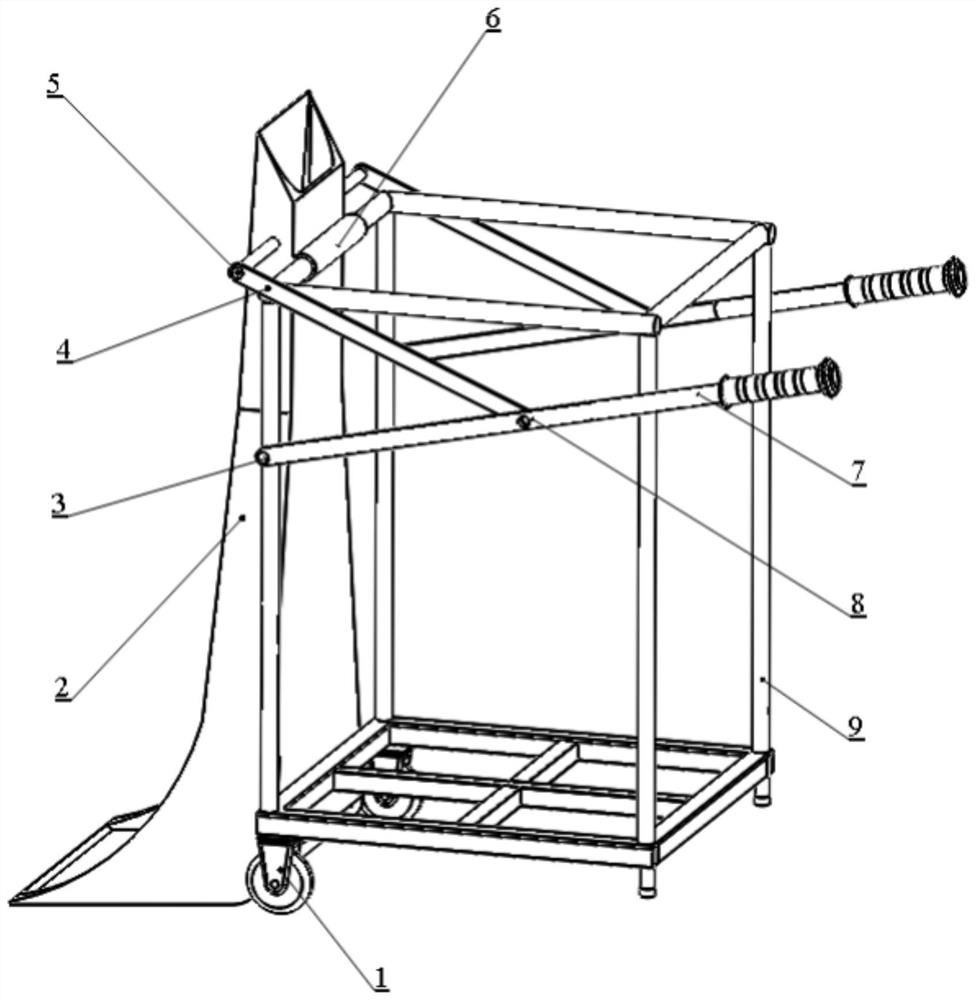

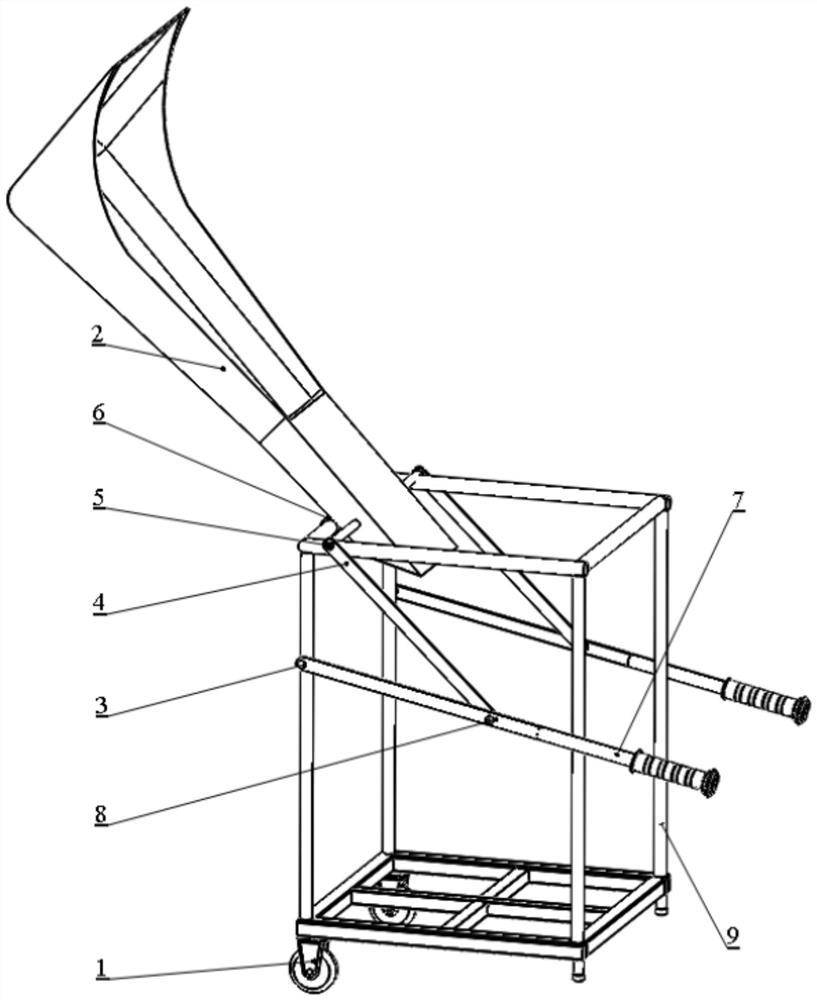

[0020] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a connecting rod type shoveling bagging machine, including a woven bag support frame 9, and guide wheels 1 are fixedly installed on the front and back sides of the bottom end of the woven bag support frame 9 , the top side of the woven bag support frame 9 is connected to the bucket 2 through the rotation of the D rotating pair 6, and the front and back sides of the bucket 2 are respectively connected to the connecting rod 4 through the rotation of the C rotating pair 5, and the connecting rod 4 is connected to the connecting rod 4 through the B rotating pair 8 Rotation is connected with cart handrail 7, and the length of cart handrail 7 is greater than the width of woven bag support frame 9, and the outer surface edge of cart handrail 7 and woven bag support frame 9 end edges fit each other, can be convenient to push cart The rotation of the handrail 7 reduces the difficulty of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com