Cloth overlock cut-off and sewing machine

A sewing machine and fabric technology, which is applied in the direction of cloth feeding mechanism, sewing machine components, sewing machine control devices, etc., can solve the problems of small cloth space, large number of machines, and high cost, achieve stable transmission of power, avoid counting errors, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following will further explain and describe the present invention through specific implementation modes. It should be understood that the purpose of the following implementation modes is to make the technical solution of the present invention clearer and easier to understand, and not to limit the protection scope of the claims.

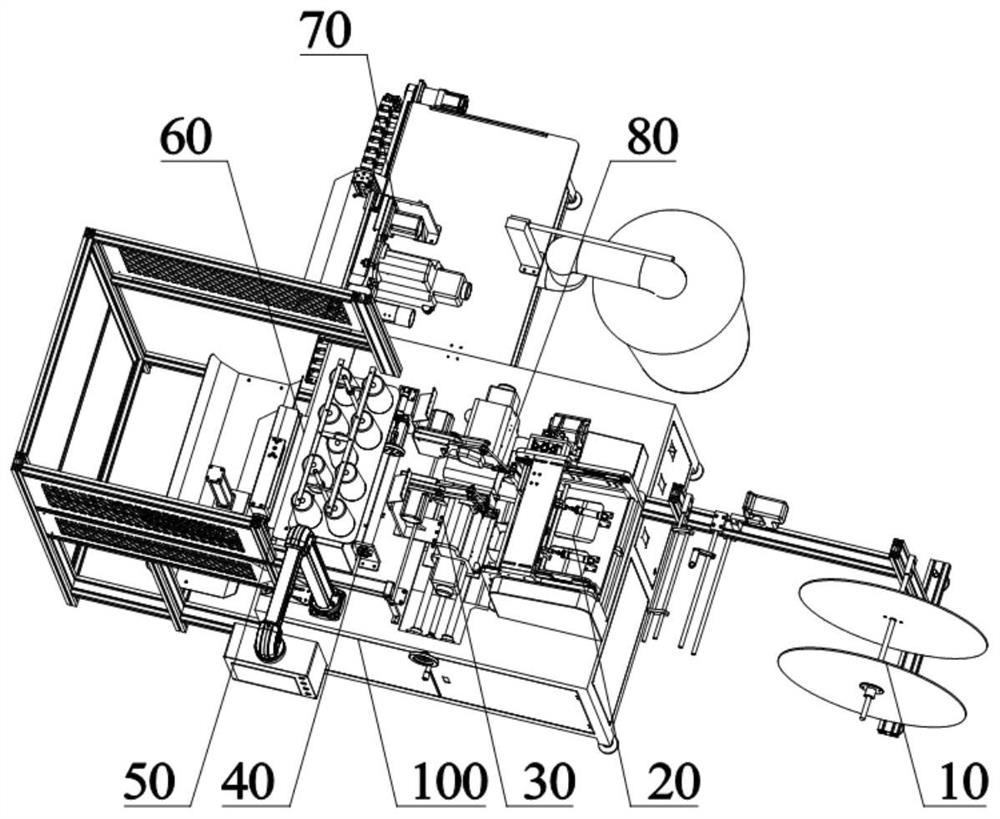

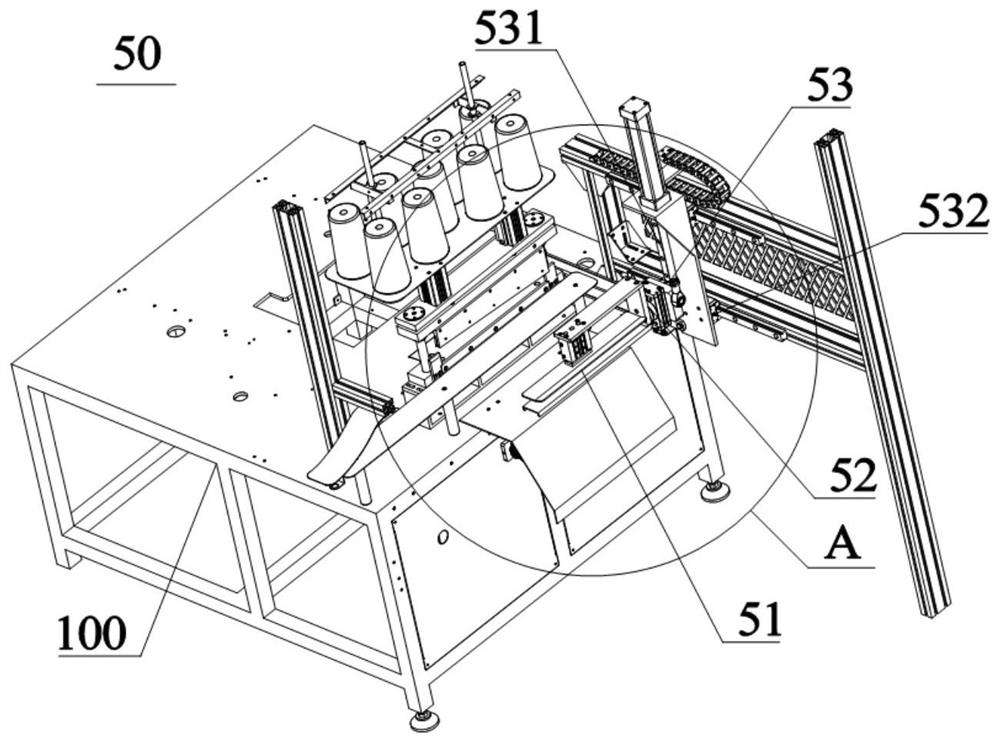

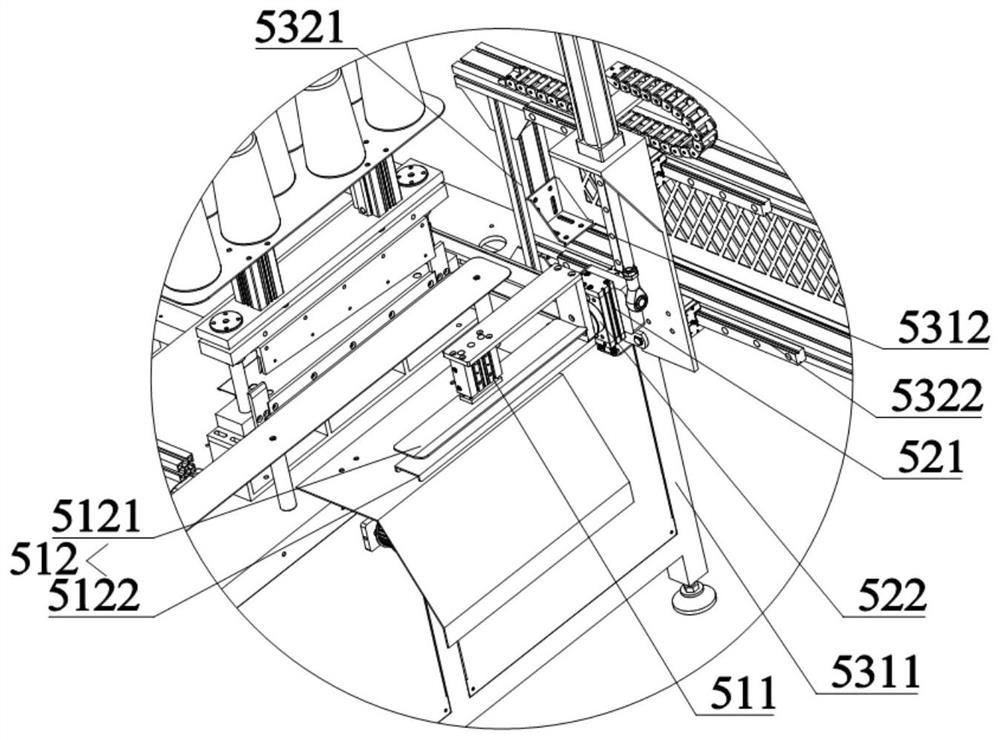

[0043] like Figure 1~3As shown, the cloth overlock cutting and sewing machine according to the present invention includes an installation structure 100, on which a discharge unit 10, a cutting unit 20, a sewing unit 30, a positioning unit 40, a rotating folding unit 50, The cutting unit 60, and the cloth sewing unit 70; the rotating and folding unit 50 includes a clamping mechanism 51 for clamping the cloth, connected with the clamping mechanism 51, and a rotating mechanism 52 whose rotation axis is perpendicular to the feeding direction, connected with the rotating mechanism 52 The movable mechanism 53; the clamping mechanism 51 clamps th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com