Cloth overlock cutting and sewing machine

A sewing machine and fabric technology, which is applied in the direction of cloth feeding mechanism, sewing machine components, sewing machine control devices, etc., can solve the problems of small cloth space, large number of machines, high cost, avoid counting errors, reduce belt vibration, and stabilize transmission. The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further explained and described below through specific embodiments, it should be understood that the purpose of the following embodiments is to make the technical solutions of the present invention clearer and easier to understand, and does not limit the protection scope of the claims.

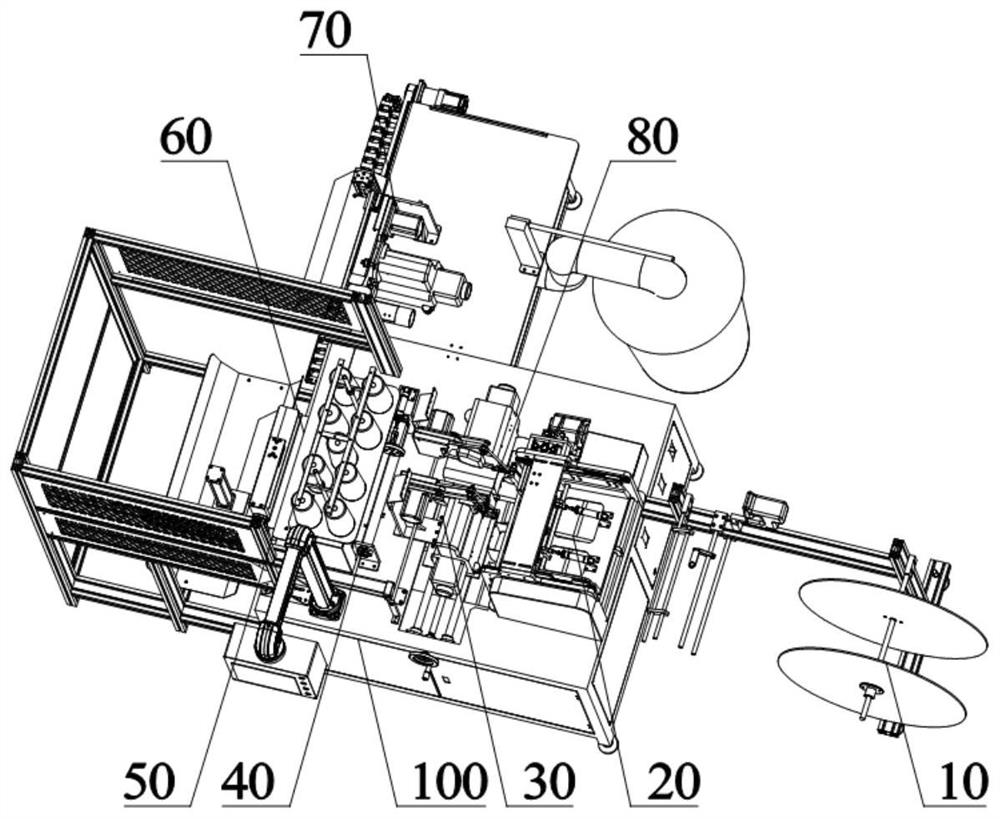

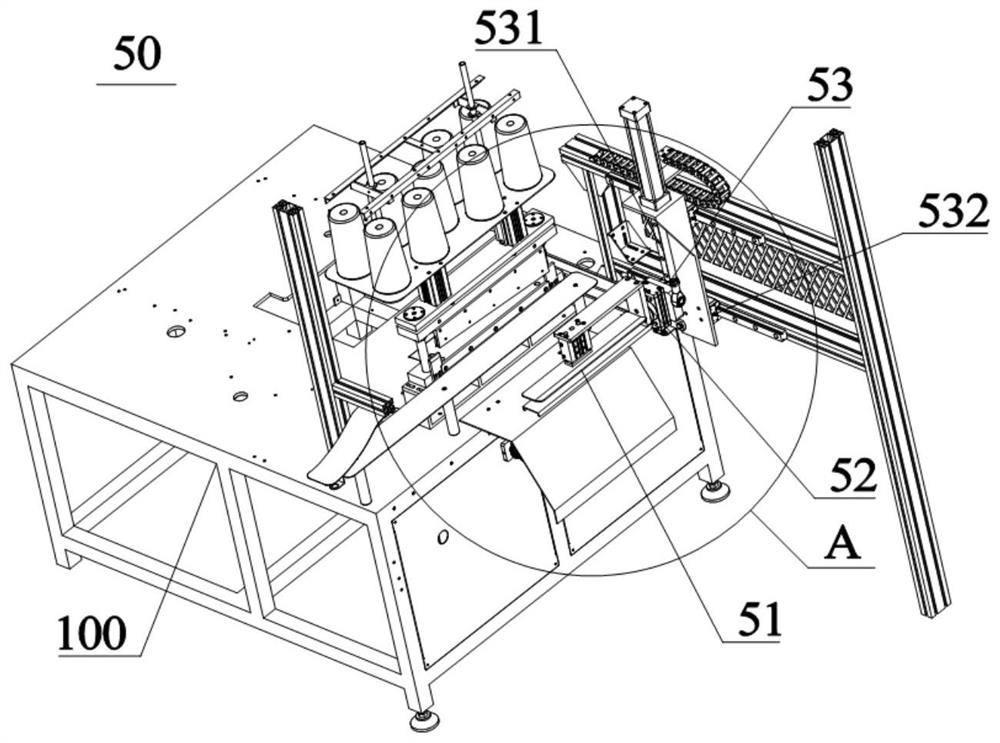

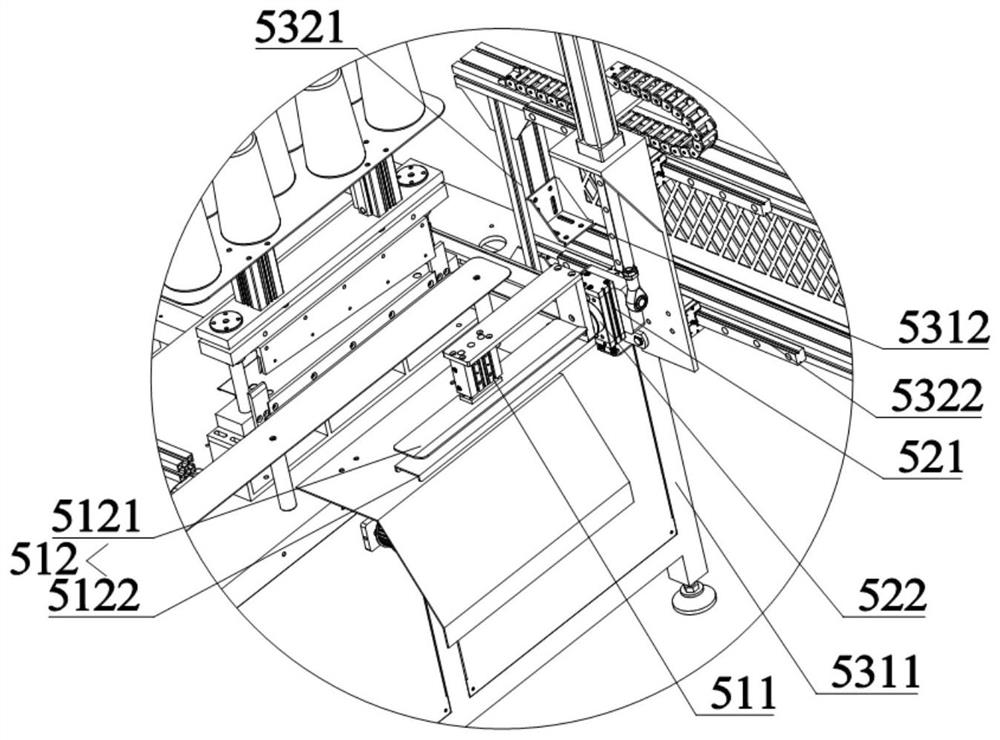

[0043] like Figures 1 to 3As shown, the cloth overlock cutting and stitching machine of the present invention includes an installation structure 100, and the installation structure 100 is sequentially provided with a discharging unit 10, a cutting unit 20, a sewing unit 30, a positioning unit 40, a rotating folding unit 50, The cutting unit 60, and the cloth sewing unit 70; the rotary folding unit 50 includes a clamping mechanism 51 for clamping cloth, a rotating mechanism 52 connected with the clamping mechanism 51, and the rotation axis is perpendicular to the feeding direction, and connected with the rotating mechanism 52 The clamping mechanism 51 clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com