Floating bridge structure and building method

A floating bridge and structural connection technology, applied in the direction of floating bridges, bridge construction, construction, etc., can solve the problems of a large number of manpower, lack of rapidity and mobility, and achieve the effect of reducing the demand for manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

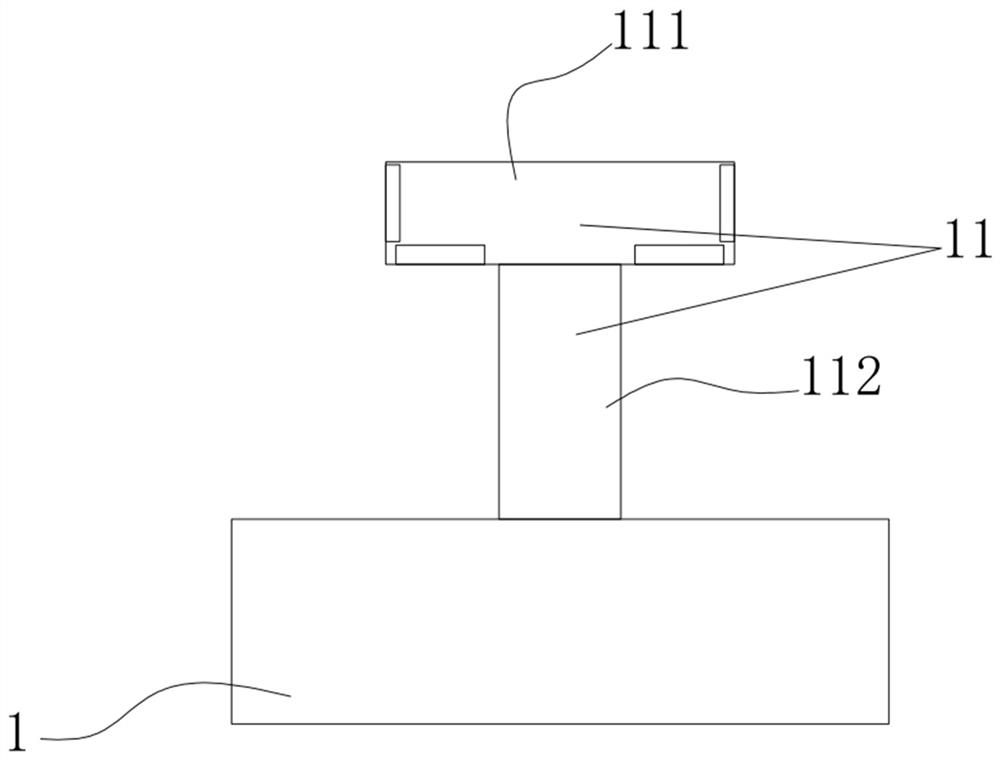

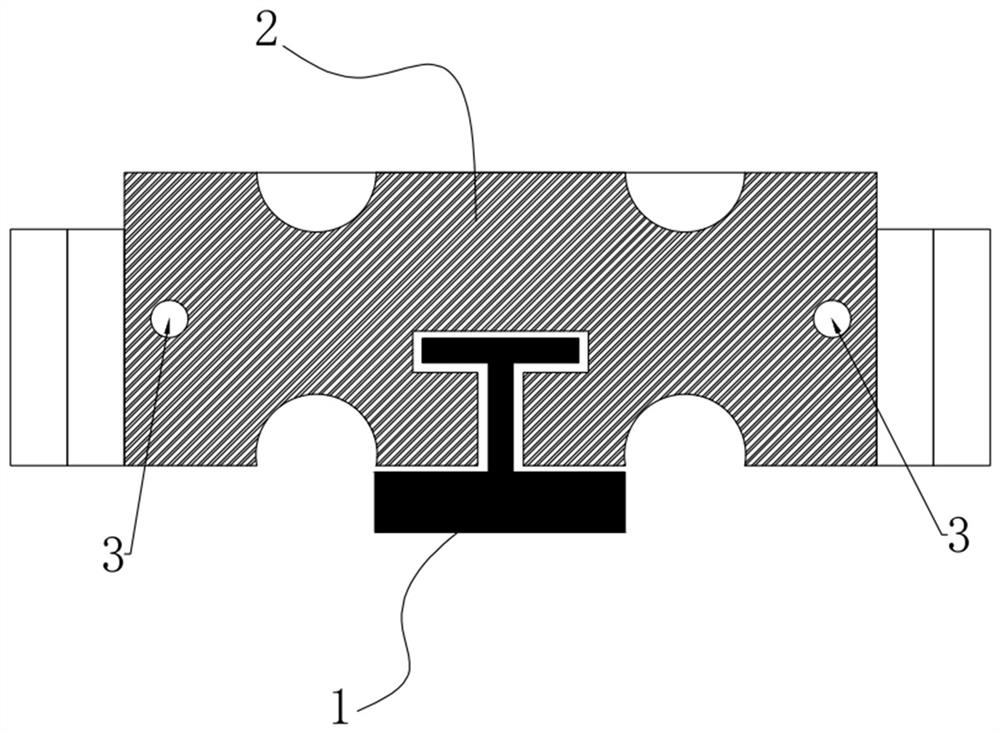

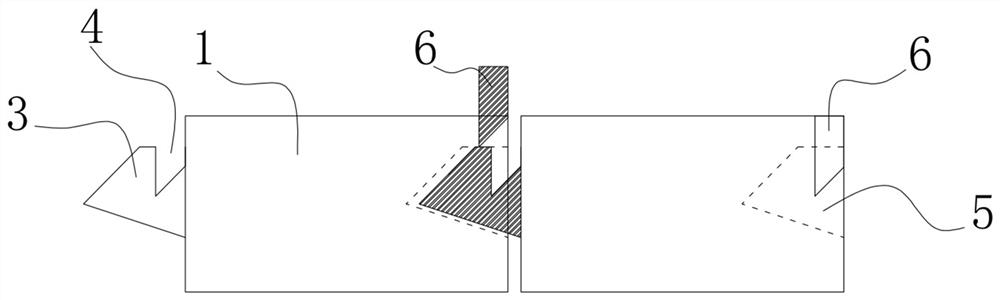

[0015] Such as figure 1 As shown, a floating bridge structure includes two positioning piles respectively arranged at both ends of the river, and a magnetic levitation track 1 is arranged between the two positioning piles. The bottom and both sides of the horizontal part 111 are provided with reaction plates and induction steel plates at intervals, and both sides of the vertical part 112 of the "T" guide rail are provided with magnetic sensors and positioning sensors; above the magnetic levitation track, multiple modules are connected end to end. The chemical buoyancy tank connects the two positioning piles to form the bridge deck; the bottom of each modular buoyancy tank is provided with a "T" groove that matches the "T" guide rail and can be embedded in the "T" guide rail; The magnet is installed on the inner wall of the "T" groove corresponding to the horizontal part of the "T" guide rail, and the positioning sensor is installed on the side wall of the "T" groove correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com