Pile hole sediment thickness detection device for engineering supervision

A sediment thickness and detection device technology, which is applied in the direction of foundation structure engineering, foundation structure test, construction, etc., can solve the problems of lack of pile hole support devices, affect casting work, and difficult to fix, so as to prolong life, increase stability, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

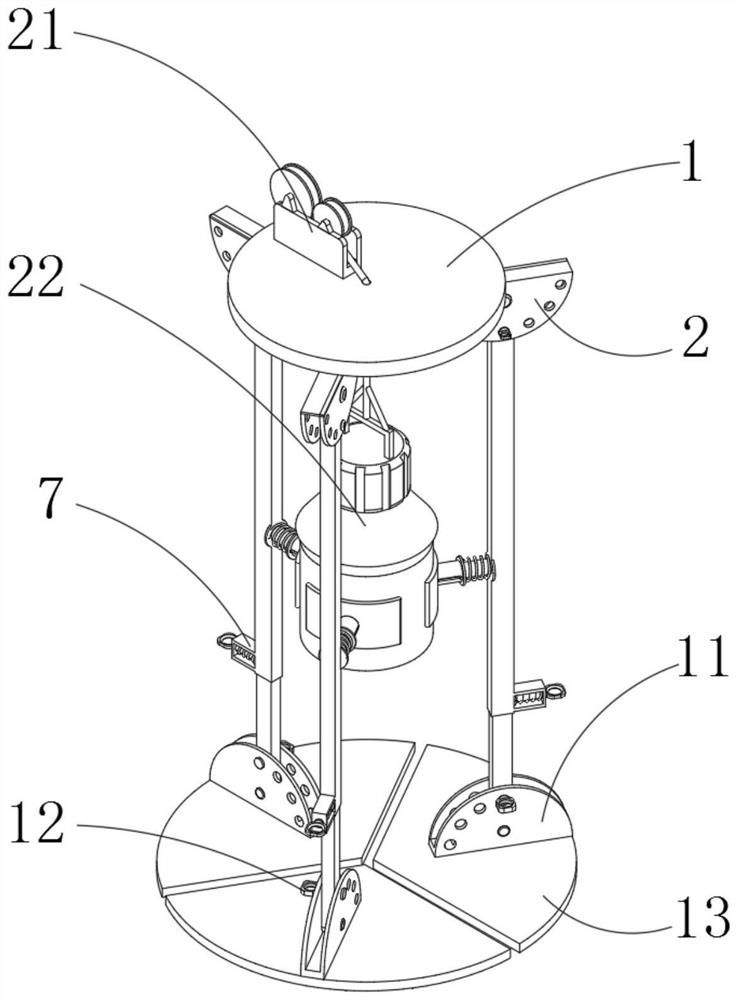

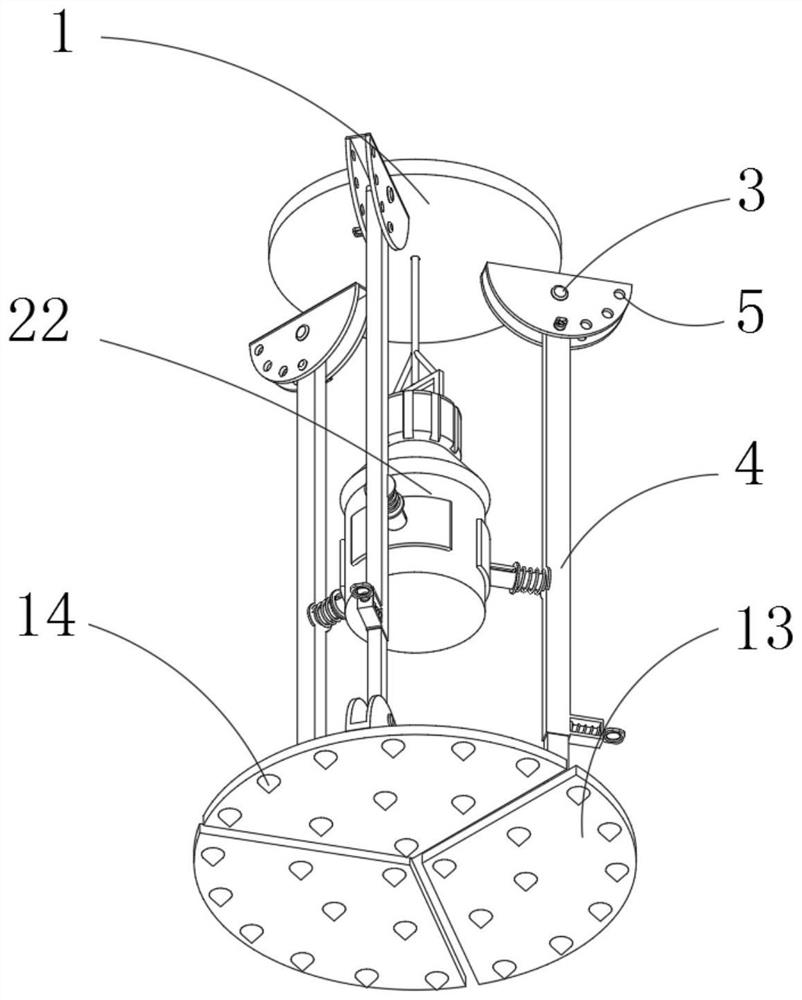

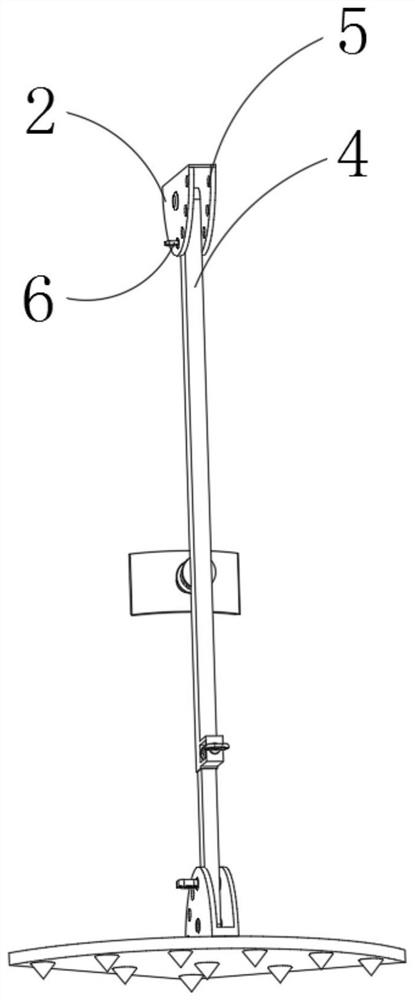

[0025] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a pile hole sediment thickness detection device for engineering supervision, including a fixed block 1, the bottom of the fixed block 1 is fixedly connected with a top arc plate 2 at an equal angle, and the inner side of the top arc plate 2 Embedded with a rotating pin 3, the outer side of the rotating pin 3 is sleeved with an adjusting rod 4, and one end of the top arc plate 2 is equiangularly provided with a fixing hole 5, and there are three top arc plates 2, and the three top arc plates 2 are fixedly connected at equal angles. The bottom end of the fixed block 1, one end of the adjusting rod 4 and the corresponding position of the rotating pin 3 are provided with a rotating hole, and the adjusting rod 4 is connected with the rotating pin 3 through the rotating hole to facilitate the quick adjustment of the angle of the adjusting rod 4. The inner side of the fixing hole 5 A fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com