Quantitative inflator pump

An inflatable cylinder and air cylinder technology, applied in the field of tire inflation, can solve the problems of easy occurrence of tire blowout, waste of manpower, slowing down of vehicle speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

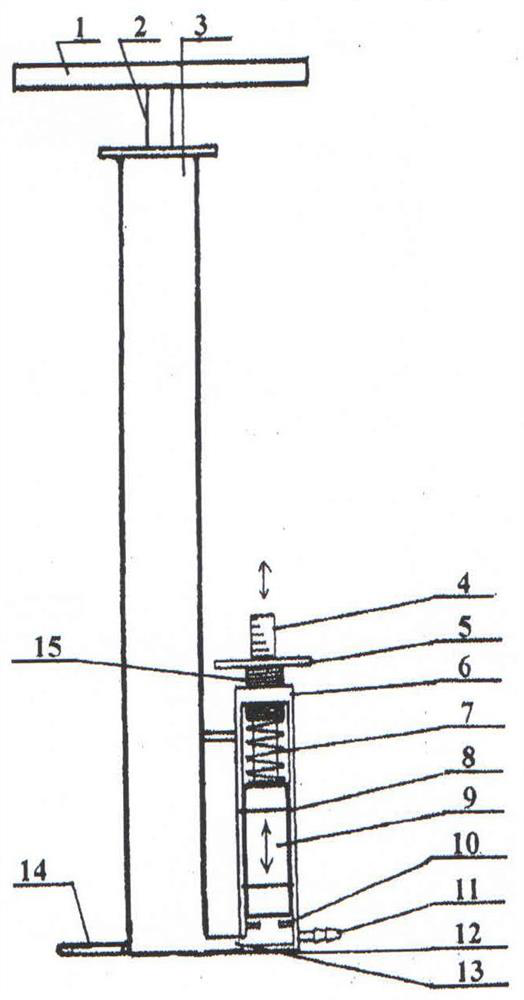

[0011] Further description will be made below in conjunction with the accompanying drawings.

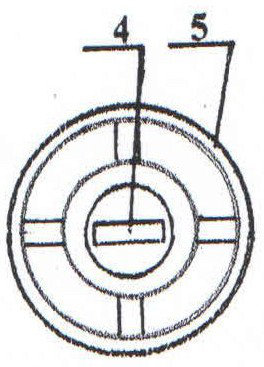

[0012] refer to figure 1 and figure 2 , the quantitative inflator is composed of the handle 2, the push rod 2, the cylinder body 3, the foot plate 14, and the jacket 6 and other components. The upper center of the jacket 6 has a screw hole (not shown) and 15 sets of hollow screws. Together, the top of the hollow screw is an outer ring 5 similar to the steering wheel, and the lower end is connected with the lower bottom plate 12 of the cylinder body 3 to be a sealed shape, and the inner edge of the lower end is connected with the gas cylinder body. The piston 9 has two ring-shaped sealing rings 8, its outer edge and the inner wall of the outer cover are close to each other, and the inner edge is close to the outer edge of the piston 9, and its upper end top of the piston is closed with The upper spring 7 sticks, and the top of the spring sticks to the top of the screw rod 15 lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com