A method of pressing and forming screw-up self-tightening nuts and self-tightening washers

A technology of pressing and forming self-tightening nuts, which is applied in the direction of nuts, locking fasteners, screws, etc., can solve the problems of nut loosening and displacement, and achieve the effects of overcoming fastening, prolonging the practical life, and simple and reasonable forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

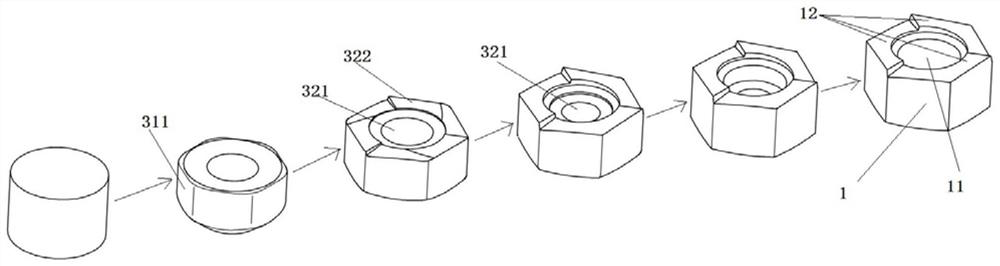

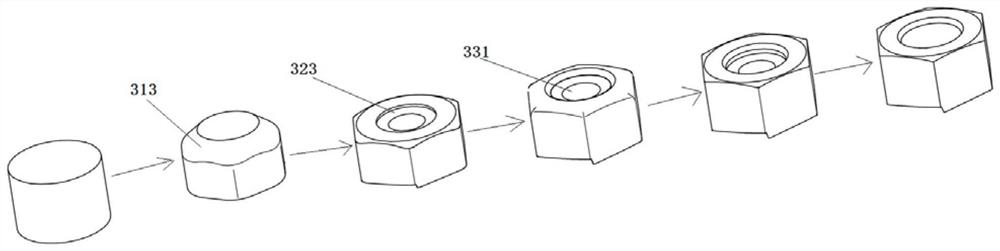

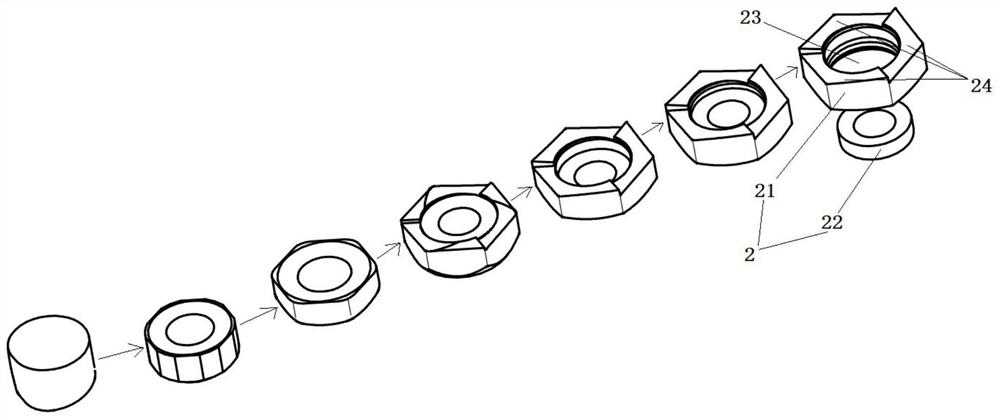

[0032] As shown in the figure, it is a press-forming method of a self-tightening nut 1 and a self-tightening washer 2. The self-tightening nut 1 is in the shape of a regular hexagon as a whole, and a first through hole 11 is arranged in the center, and a Screw thread; two or more first swivel bosses 12 that are connected head to tail are arranged directly above the self-tightening nut 1, and the whole surrounds a closed figure, wherein each section of the first swivel boss 12 has the same shape, the first The head-to-tail height difference of the swivel boss 12 is fixed, the height difference between the inside and the outside of the first swivel boss 12 is in a fixed ratio according to the effective width of the swivel surface, and the middle height of the first swivel boss 12 adopts linear Variety;

[0033] The self-tightening gasket 2 includes a top 21 and a bottom 22, the top 21 is a driven structure, the bottom 22 is a stop structure, the driven structure of the top 21 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com