Method for evaluating insulation aging of XLPE cable based on polarization factor

A cable insulation and insulation aging technology, applied in the direction of measuring electricity, measuring electrical variables, testing dielectric strength, etc., can solve problems such as insulation breakdown, reduce the insulation performance of XLPE cables, and threaten the safe operation of XLPE cables, so as to reduce the workload , Improve the efficiency of operation and maintenance management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

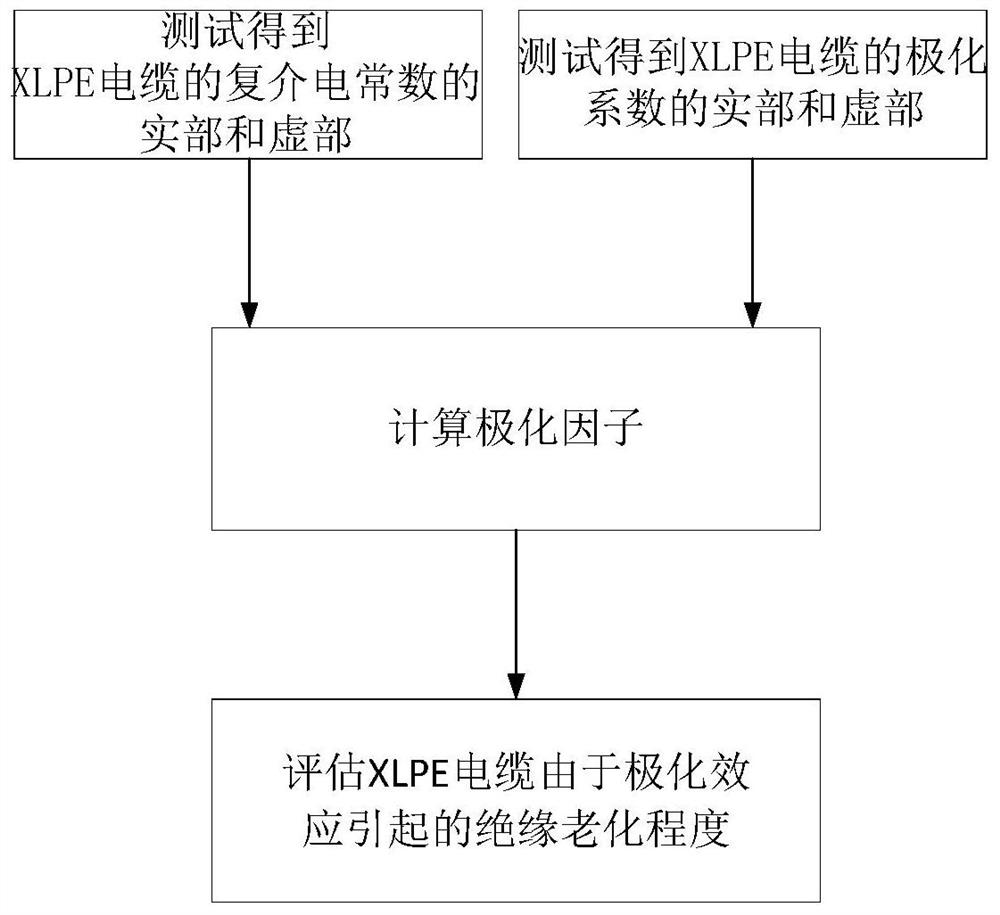

[0013] figure 1 It is a flow chart of the evaluation method for the insulation aging degree of XLPE cables due to polarization effects, by figure 1 It can be seen that a method for evaluating the aging of XLPE cable insulation based on polarization factor includes the following steps:

[0014] Step 1: Select the XLPE cable sample and test to obtain the complex dielectric constant and polarization coefficient of the XLPE cable sample:

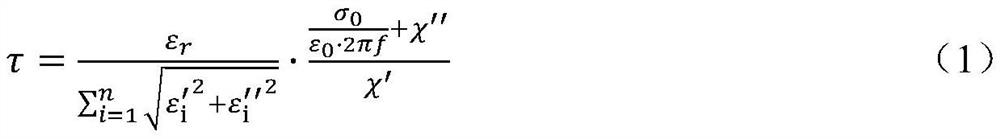

[0015] Select XLPE cables aged 72h, 144h,...,t at 150°C in the laboratory as test samples, where t is the aging time, t∈{72n|n=1,2,...,10}. The real part and imaginary part of the power frequency complex permittivity of the cable are obtained by using a dielectric spectrum tester, which are recorded as ε′ respectively 1 ,ε′ 2 ,…,ε′ n and ε″ 1 ,ε″ 2 ,…,ε″ n ; Utilize the polarization / depolarization current method (PDC) test to obtain the real part χ ' and the imaginary part χ " of the polarization coefficient of the dielectric response of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com