Tantalum nitride thin film resistor and preparation method thereof

A thin film resistor, tantalum nitride technology, applied in thin film resistors, resistor manufacturing, resistors, etc., can solve the problems of resistance fluctuation of tantalum nitride thin film resistors, achieve high stability and consistency, and improve resistance stability performance, good resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

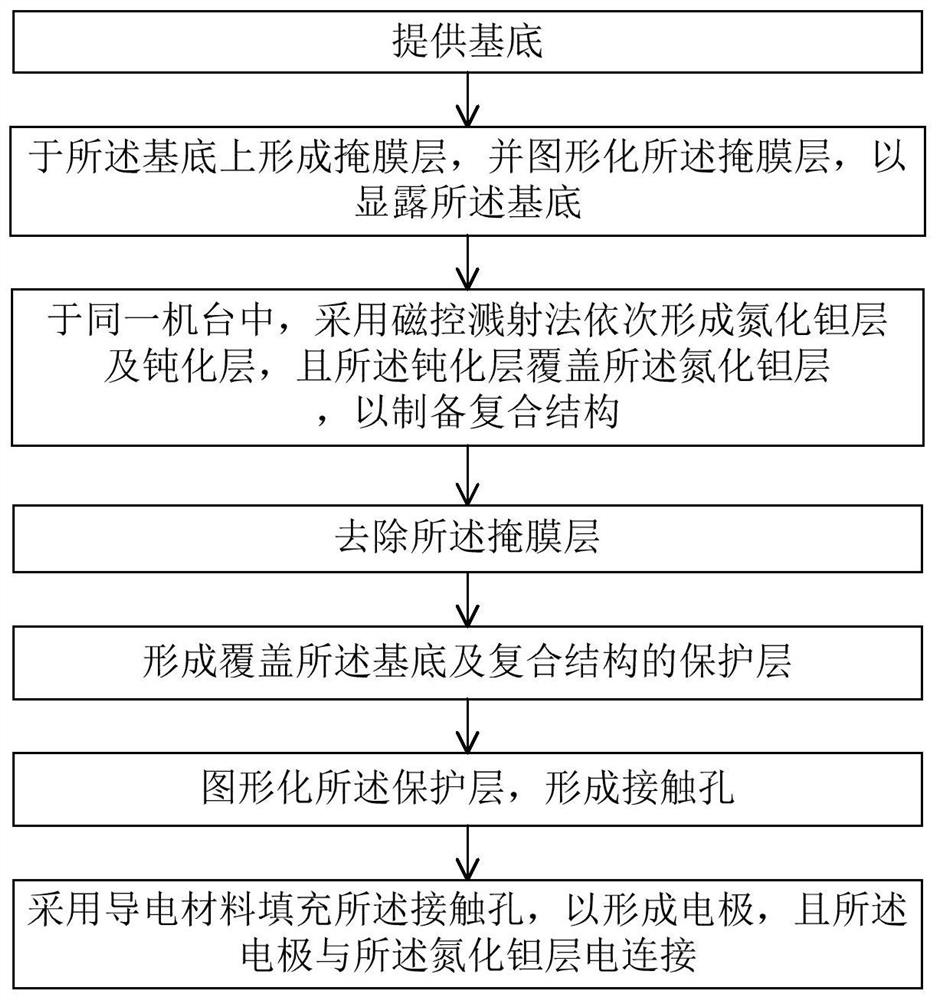

[0043] refer to figure 1 , this embodiment provides a method for preparing a tantalum nitride thin film resistor. In the same machine, a composite structure of sequentially stacked tantalum nitride layers and passivation layers is formed by using the magnetron sputtering method, so that through the passivation The tantalum nitride layer can protect the tantalum nitride layer and prevent the tantalum nitride layer from being in contact with the external environment, so that the tantalum nitride layer has good resistance stability.

[0044] refer to Figure 2 ~ Figure 6b , the preparation process and structure of the tantalum nitride thin film resistor will be further described below in conjunction with the drawings and specific embodiments.

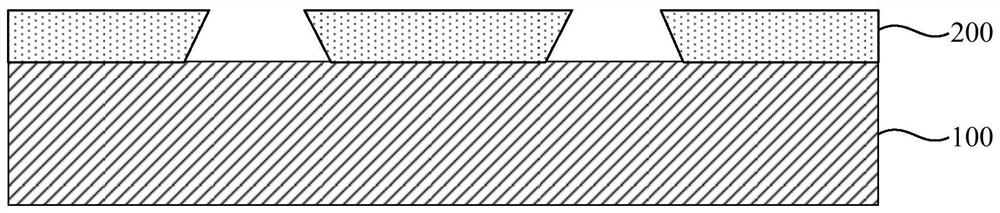

[0045] First, see figure 2 , providing a substrate 100 , and forming a patterned mask layer 200 on the substrate 100 to expose the substrate 100 .

[0046] Specifically, the substrate 100 may include one of a silicon layer, a silicon o...

Embodiment 2

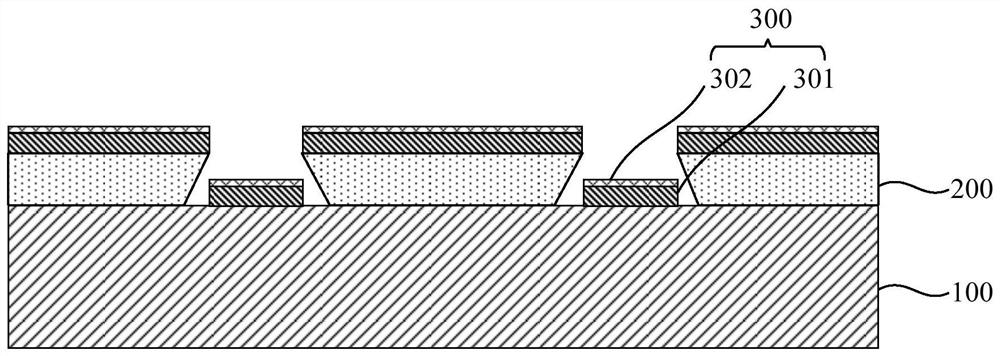

[0059] refer to Figure 7 , this embodiment also provides another tantalum nitride thin film resistor and its preparation method. The main difference between this embodiment and Embodiment 1 is that the passivation layer in this embodiment adopts a conductive layer 312 with conductivity . Wherein, for the specific preparation method and structure of the tantalum nitride thin film resistor, please refer to Embodiment 1.

[0060] In this embodiment, the tantalum nitride thin film resistor includes a substrate 110, a composite structure 310, a protective layer 410, and an electrode 510, wherein the composite structure 310 is located on the substrate 110, and the composite structure 310 includes sequentially stacked A tantalum nitride layer 311 and a conductive layer 312, wherein the tantalum nitride layer 311 is in contact with the substrate 110, the conductive layer 312 covers the tantalum nitride layer 311; the protective layer 410 covers the The substrate 110 and the composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com