Vehicle-mounted high-definition camera

A high-definition camera and lens technology, applied in image communication, vehicle parts, TV, etc., can solve the problem of damaging shielding performance, and achieve the effect of simple shielding and waterproof structure, stable and reliable waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

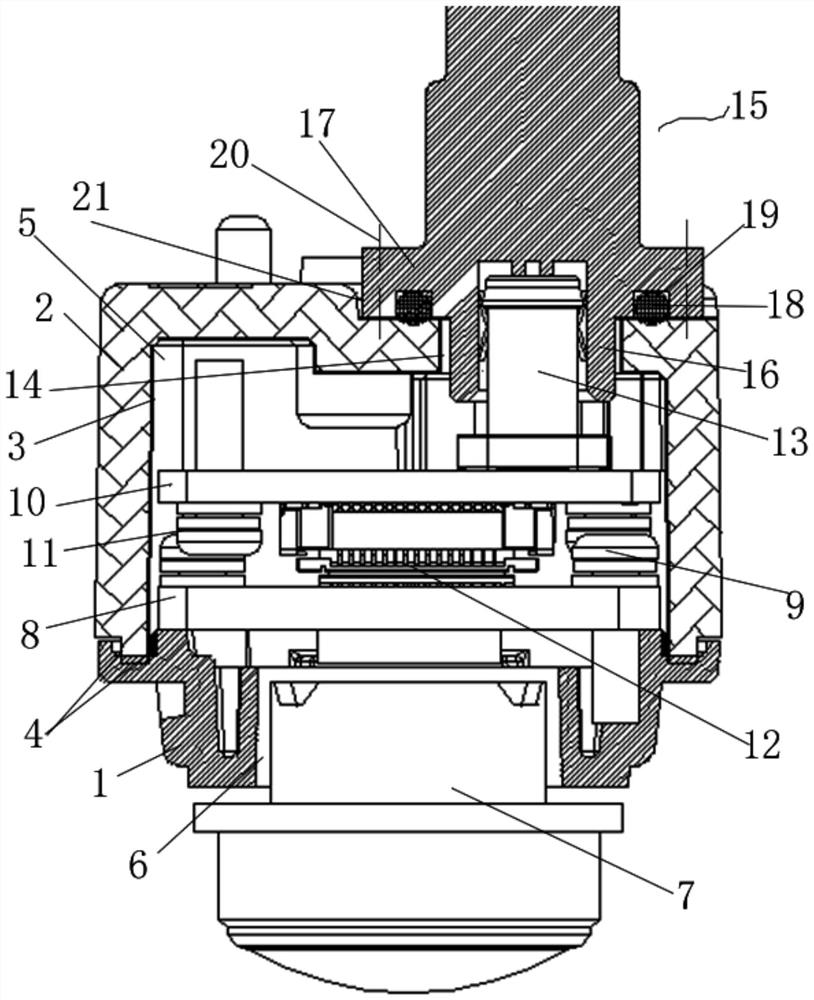

[0012] A vehicle-mounted high-definition camera, see figure 1 : It includes a front shell 1 and a rear shell 2, the inner walls of the front shell 1 and the rear shell 2 are respectively arranged with an electroplating layer 3, and the assembly seams 4 of the front shell 1 and the rear shell 2 are assembled and welded to form an overall installation cavity 5, The front end center hole 6 of the front case 1 is positioned with a front-protruding lens 7, the first circuit board 8 is fixed in the installation cavity of the front case 1 through the first screw 9, and the first circuit board 8 and the front case 1 form a contact guide. Through, the second circuit board 10 is fixed in the installation cavity of the rear shell 2 through the second screw 11, and the second circuit board 10 and the rear shell 2 form contact conduction, between the first circuit board 8 and the second circuit board 10 A connector 12 is arranged, and the connector 12 is used for the connection between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com