A two-stage hdmi connector and its manufacturing method

A technology of HDMI connector and manufacturing method, which is applied in the field of two-stage HDMI connector and its manufacturing, can solve the problems of insufficient bite force between the iron shell and the tongue, tight raised ribs, limited thickness of the iron shell, etc., and achieve the protection against electromagnetic waves Enhanced leakage, reduced gaps, and enhanced anti-interference effects from external signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

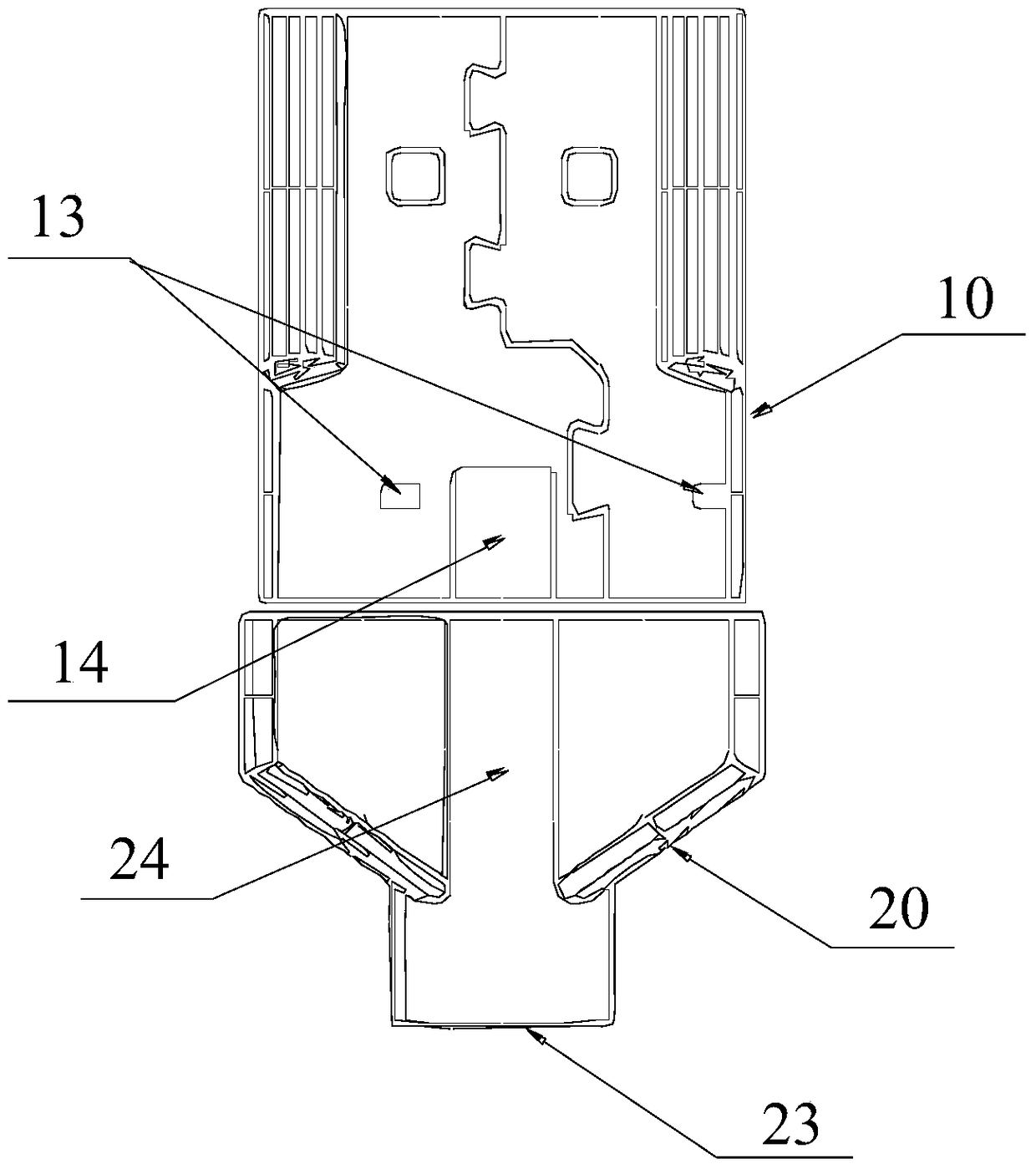

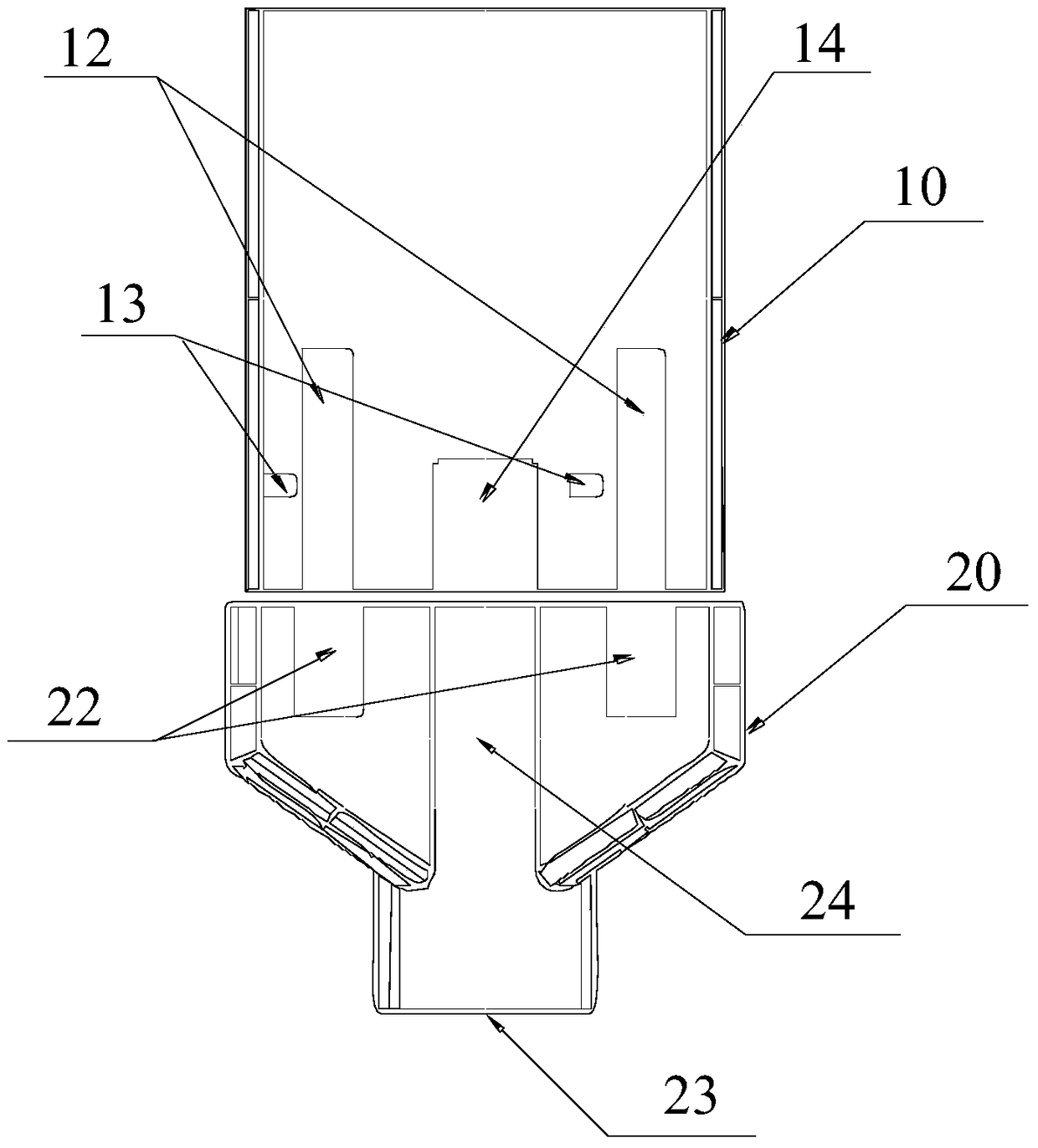

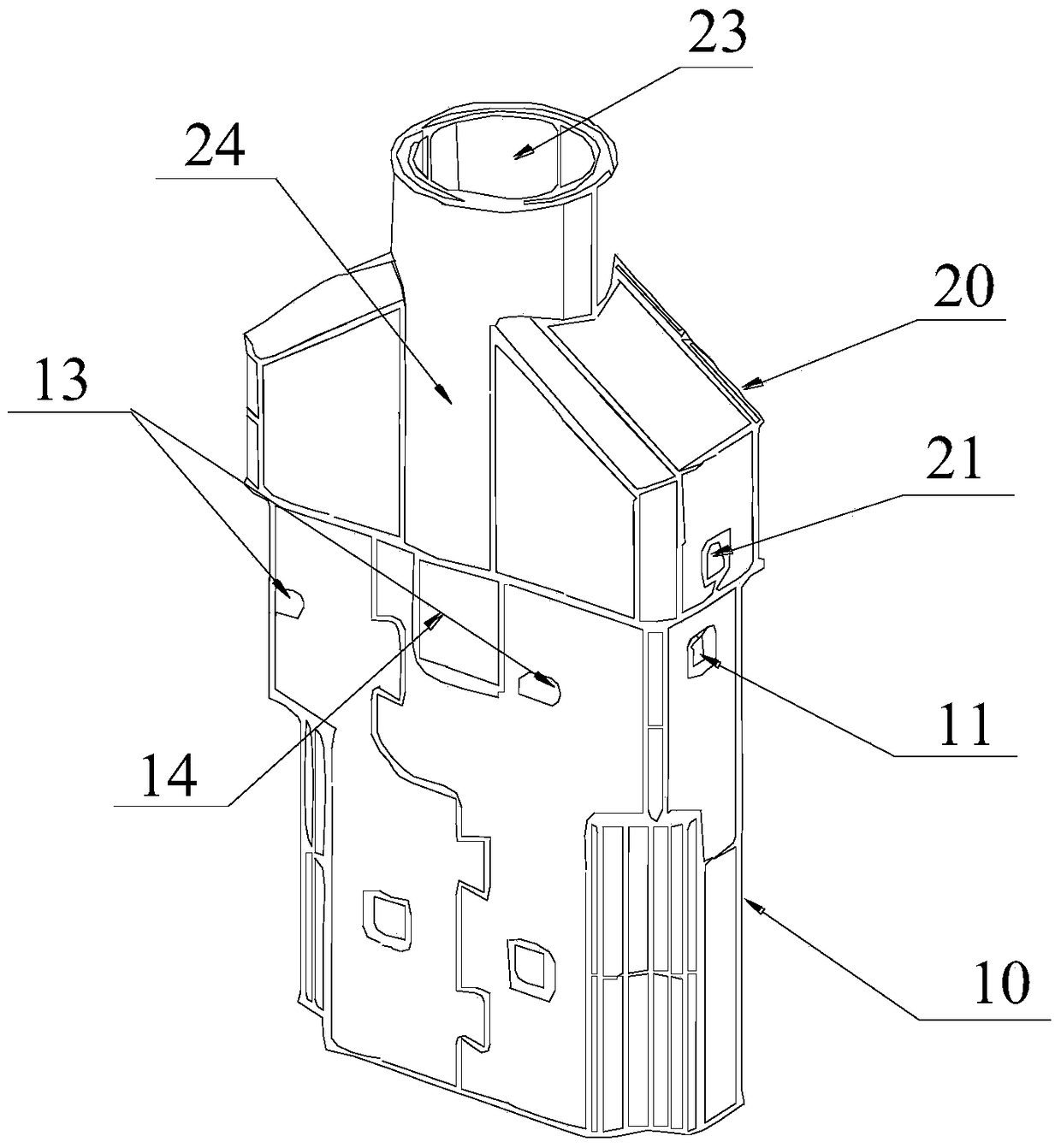

[0027] refer to Figure 1 to Figure 3 , propose an embodiment of a two-stage HDMI connector of the present invention:

[0028] A two-stage HDMI connector, the shielding shell of which is composed of two parts: the front end part 10 of the shell and the rear cover part 20 of the shell. The front end 10 of the housing is integrally formed, which adopts a complete iron sheet which is folded left and right to form a prototype and then stamped. The manufacturing process is simple and effectively reduces the occurrence of gaps. The front end portion 10 of the casing includes a tongue part, an extension part and a connection part for connecting with the rear cover in sequence from front to back. The shell rear cover 20 is integrally formed, which is stamped and formed by a complete iron sheet, the manufacturing process is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com