Hollow glass separation aluminum frame gluing device with correction function

A gluing device and aluminum frame technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of missing glue in a large number of positions of the aluminum frame, reducing the sealing performance of the bonded glass, and low strength, etc., to achieve Eliminate glue contact and the effect of glue failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

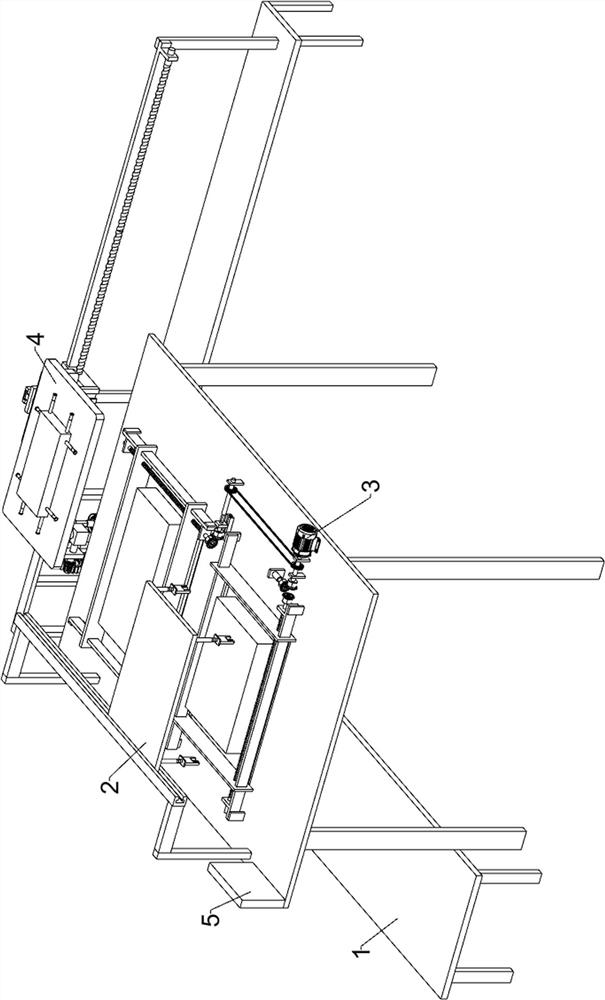

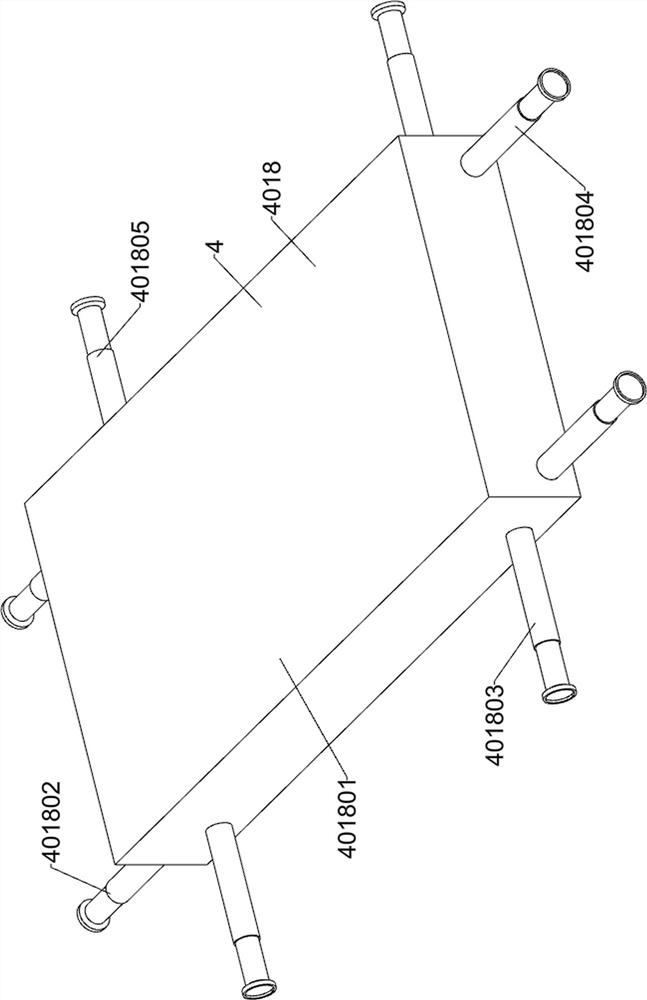

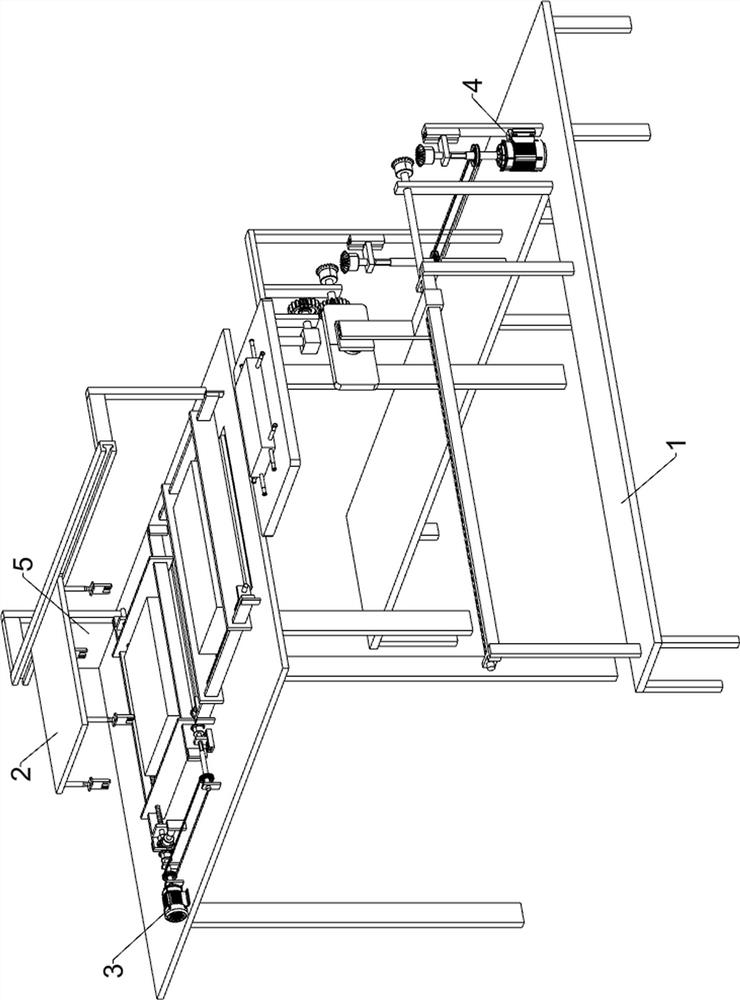

[0028] A gluing device for hollow glass aluminum frame with correction function, such as Figure 1-6 As shown, it includes chassis 1, transportation component 2, correction component 3, glue application component 4 and control panel 5; chassis 1 is connected with transportation component 2; chassis 1 is connected with correction component 3; chassis 1 is connected with The gluing assembly 4 is connected; the top of the bottom frame 1 is connected with the control panel 5 .

[0029] Working principle: When preparing for work, place the device on a horizontal surface, and make some components of the gluing unit 4 flush with the gluing machine, put the aluminum frame into the correcting unit 3, turn on the power, and then operate the bottom frame 1 The control panel 5 on the upper control device starts to operate, and the straightening component 3 flattens the short sides of the curved aluminum frame in turn, and then the transport component 2 drives the aluminum frame to move to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com