Plate stretching and punching die

A sheet metal and punching technology, applied in the direction of perforating tools, forming tools, manufacturing tools, etc., can solve the problems of poor sheet forming effect, inaccurate forming size, high equipment cost, etc., and achieve simple structure, accurate forming size and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

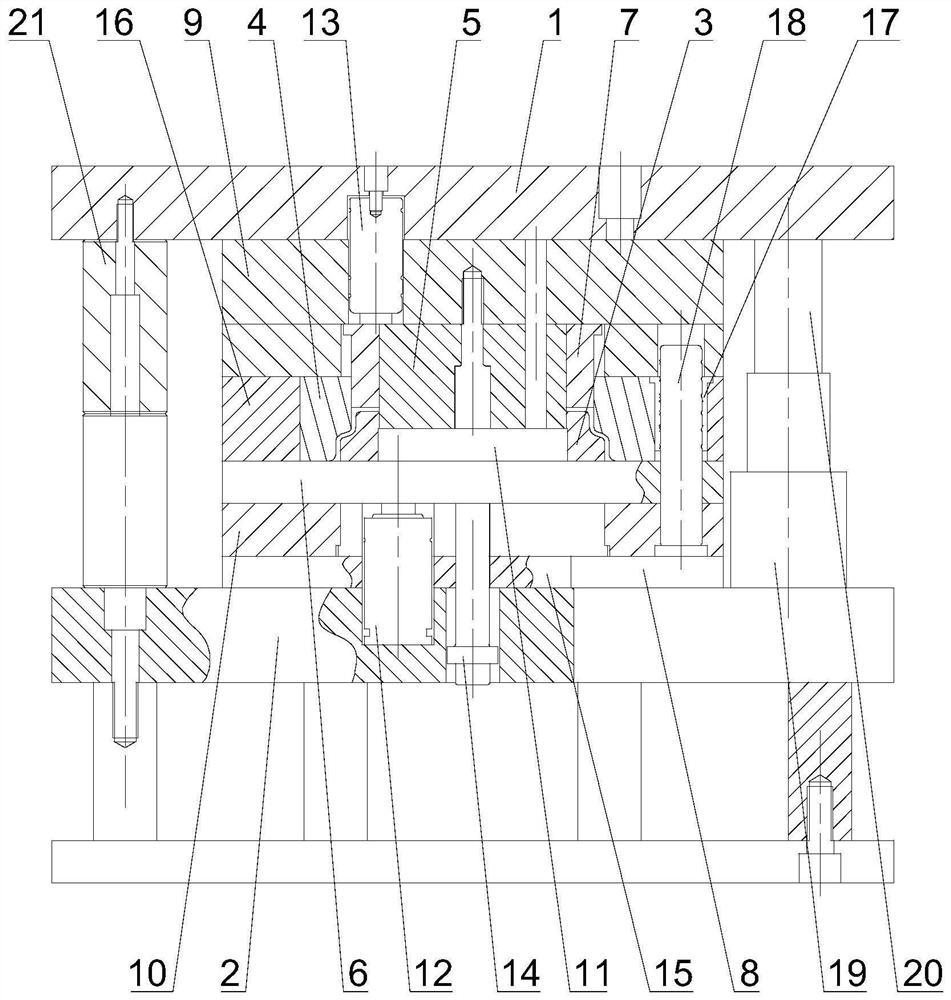

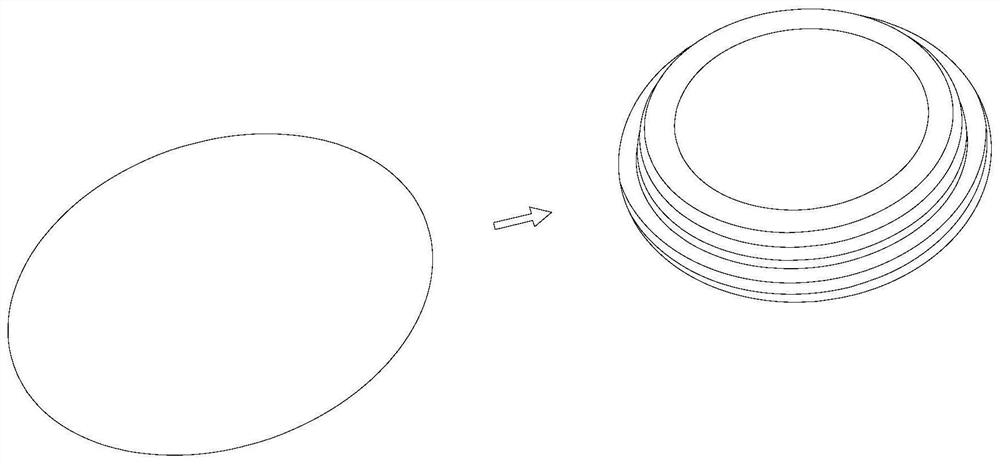

[0020] see figure 1 with 2 As shown, this embodiment provides a sheet metal drawing punching die, which includes an upper die base 1, a lower die base 2, a punch 3, a die 4, a punch 5, a binder plate 6 and a stripper block 7 .

[0021] The lower die base 2 is provided with a lower backing plate 8, the upper die base 1 is provided with an upper backing plate 9, the punch 3 is fixed on the lower backing plate 8 by a fixed plate 10, and the die 4 is installed on the upper backing plate 9 and connected with The punch 3 cooperates to complete the side drawing forming of the product. In particular, in the case of obvious springback, you can set the stretch increment to reserve the amount of springback.

[0022] The punch 3 is provided with a central hole 11, and the punch 5 is fixed on the upper back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com