Color resistive ink and preparation method thereof

A resistance and color technology, applied in the field of color resistance ink and its preparation, can solve the problems of monotonous color, low resistivity, low template drawing efficiency, etc., and achieve the effects of low production cost, good bending resistance and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The colored resistance ink in the present embodiment adopts following method to make: (1), take 32% propylene glycol methyl ether, 15% polyvinyl butyral, 8% polyaniline, 12% chlorinated Cuprous, 6% red dye, 22% ethanol, 1% surfactant, 3% erucamide, 0.5% antistatic agent and 0.5% wax powder, first propylene glycol methyl ether, polyvinyl alcohol Butyral is put into the mixer and mixed, then polyaniline is added, and the conductive link material is obtained after mixing;

[0017] (2), then cuprous chloride, red dye, ethanol, surfactant, erucamide, antistatic agent and wax powder are put into the mixer and mixed, and finally the product obtained is ground with a sand mill to prepare Obtain the colored resistance ink.

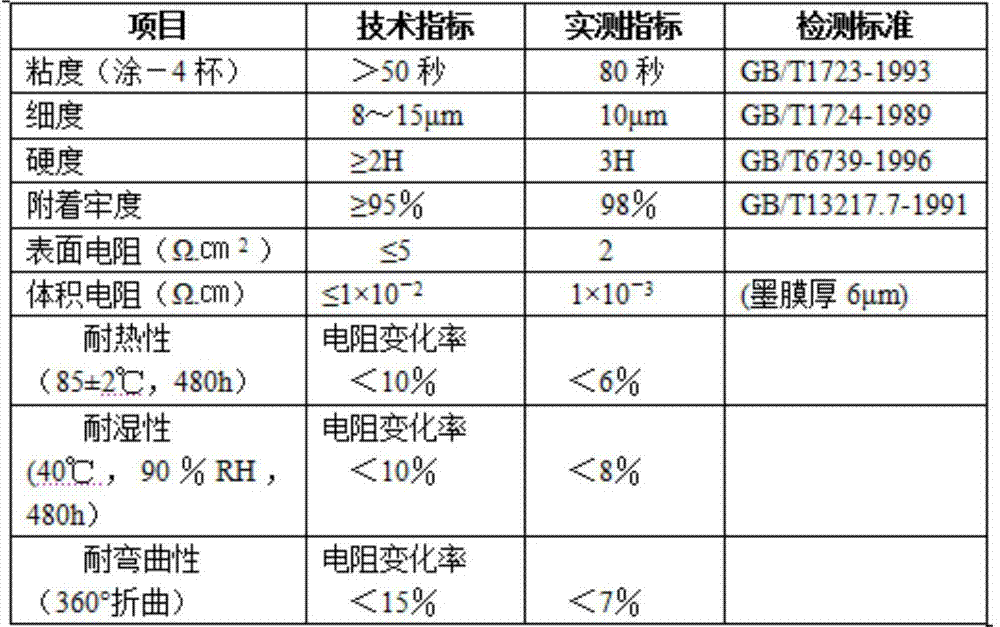

[0018] The various performance testing results of the color resistance ink prepared in the present embodiment are as follows:

[0019]

[0020] This product is drawn on the polyester film by the template drawing method, and the thin film switch thin fil...

Embodiment 2

[0022] The colored resistance ink in the present embodiment adopts following method to make: (1), take 30% propylene glycol methyl ether, 15% polyvinyl butyral, 9% polyaniline, 12% chlorinated Cuprous, 6% yellow dye, 24% ethanol, 1% surfactant, 2% erucamide, 0.5% antistatic agent and 0.5% wax powder, first propylene glycol methyl ether, polyvinyl alcohol Butyral is put into the mixer and mixed, then polyaniline is added, and the conductive link material is obtained after mixing;

[0023] (2), then cuprous chloride, yellow dye, ethanol, surfactant, erucamide, antistatic agent and wax powder are dropped into the mixer and mixed, and finally the product obtained is ground with a sand mill to prepare Obtain the colored resistance ink.

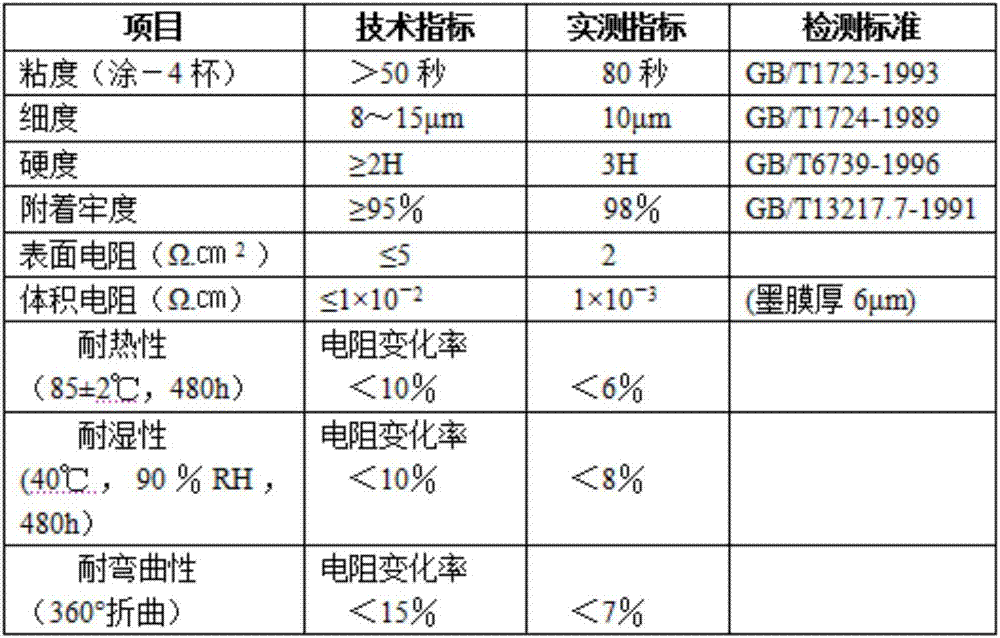

[0024] The various performance testing results of the color resistance ink prepared in the present embodiment are as follows:

[0025]

[0026] This product is drawn on the polyester film by the template drawing method, and the thin film switc...

Embodiment 3

[0028] The color resistance ink in the present embodiment adopts following method to make: (1), take 31% propylene glycol methyl ether, 16% polyvinyl butyral, 8% polyaniline, 10% chlorinated Cuprous, 7% blue dye, 24% ethanol, 1% surfactant, 2% erucamide, 0.5% antistatic agent and 0.5% wax powder, first propylene glycol methyl ether, polyethylene Alcohol butyral is put into the agitator and mixed, then polyaniline is added, and the conductive link material is obtained after mixing;

[0029] (2), then cuprous chloride, blue dye, ethanol, surfactant, erucamide, antistatic agent and wax powder are dropped into the agitator and mixed, and finally the resulting product is ground with a sand mill, that is The colored resistive ink is prepared.

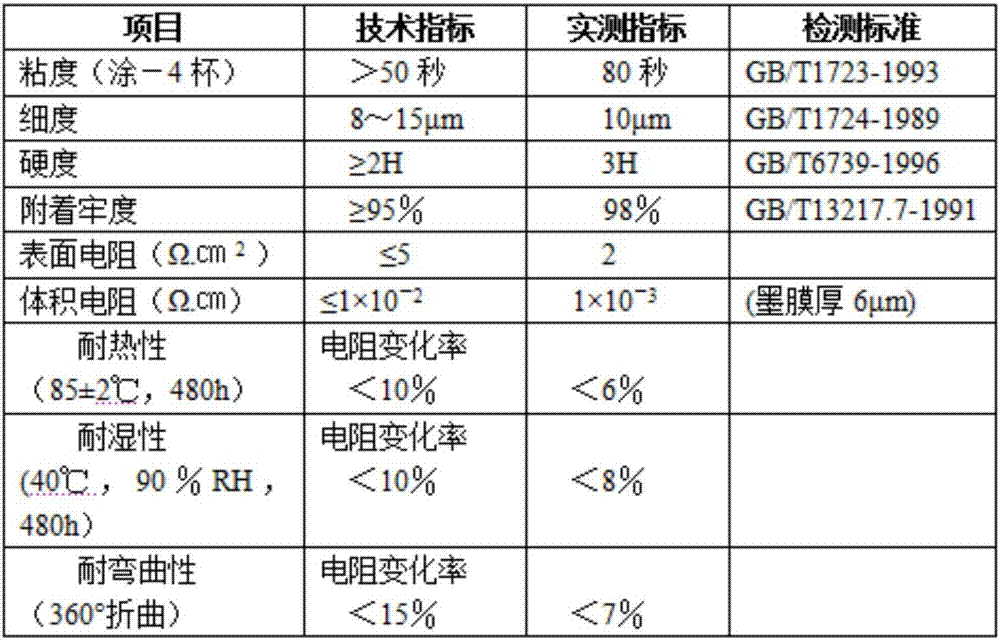

[0030] The various performance testing results of the color resistance ink prepared in the present embodiment are as follows:

[0031]

[0032] This product is drawn on the polyester film by the template drawing method, and the thin film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com