Patents

Literature

30results about How to "Stable drawing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing platy or lump processed cheese and cheese obtained

ActiveCN101564062AMaintain drawabilityLow heating temperatureCheese manufactureEngineeringBrowning reaction

The invention discloses a method for preparing a platy or lump processed cheese, comprising steps as follows: (1) shearing and mixing materials which contain natural cheese, butter oil, emulsifying salt and water; (2) heating under the shearing condition; (3) shearing emulsification; (4) forming the platy or lump cheese and then cooling. The method is characterized in that: both the shearing condition in step (2) and shearing emulsification in step (3) use a cutter with a blade thickness of 2-10mm, at a shearing rotating speed of 200-800rpm; in step (2), the materials are heated to 70-80 DEG C; and in step (3), the temperature for shearing emulsification ranges from 70 to 80 DEG C. The invention also discloses a platy or lump processed cheese prepared by the method. The invention improves the prior technique for preparing processed cheese by using low shearing condition to overcome the defect that the prior processed cheese has no stringiness, and provides a platy or lump processed cheese with stringiness, favorable mouth feel and texture and long guarantee period without browning reaction.

Owner:BRIGHT DAIRY & FOOD

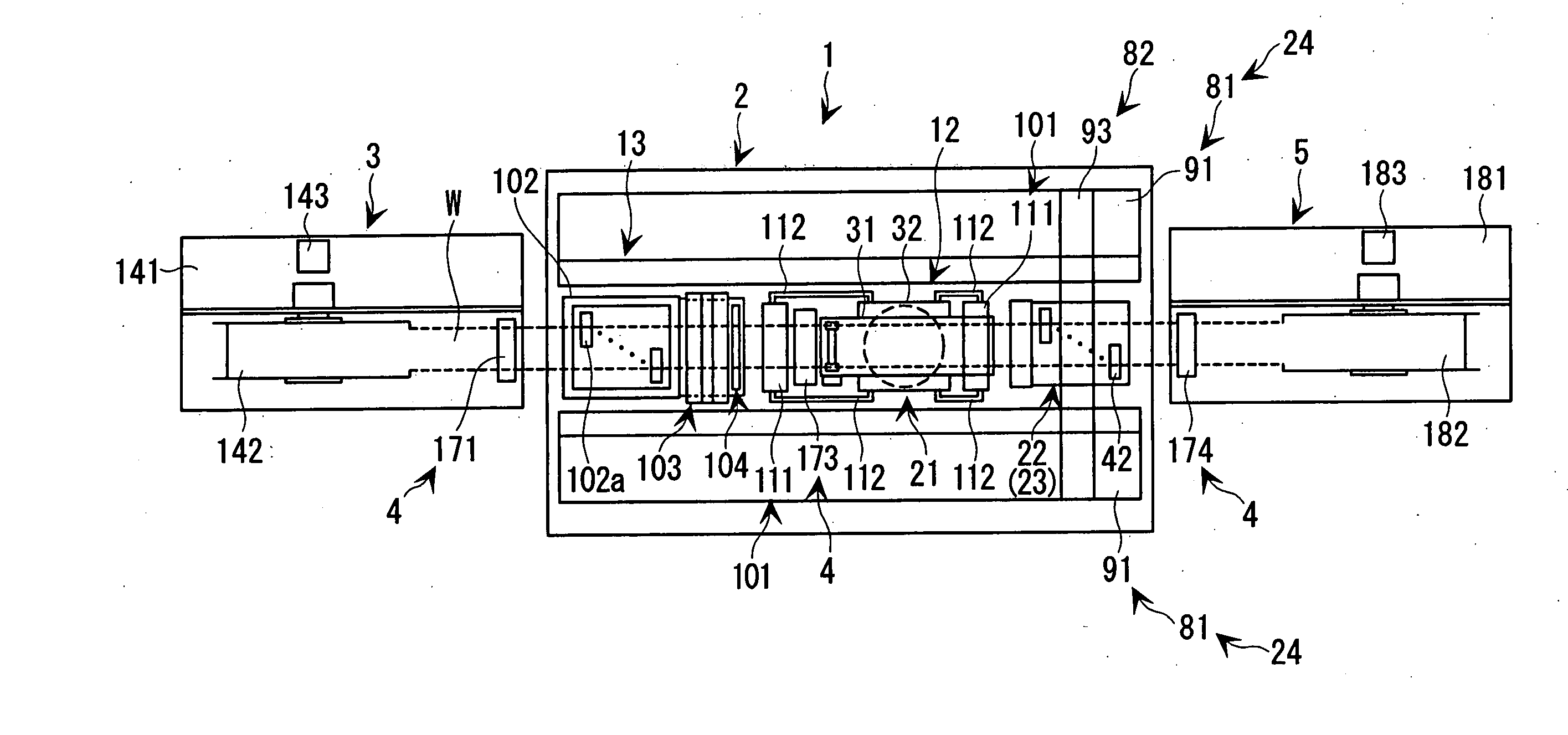

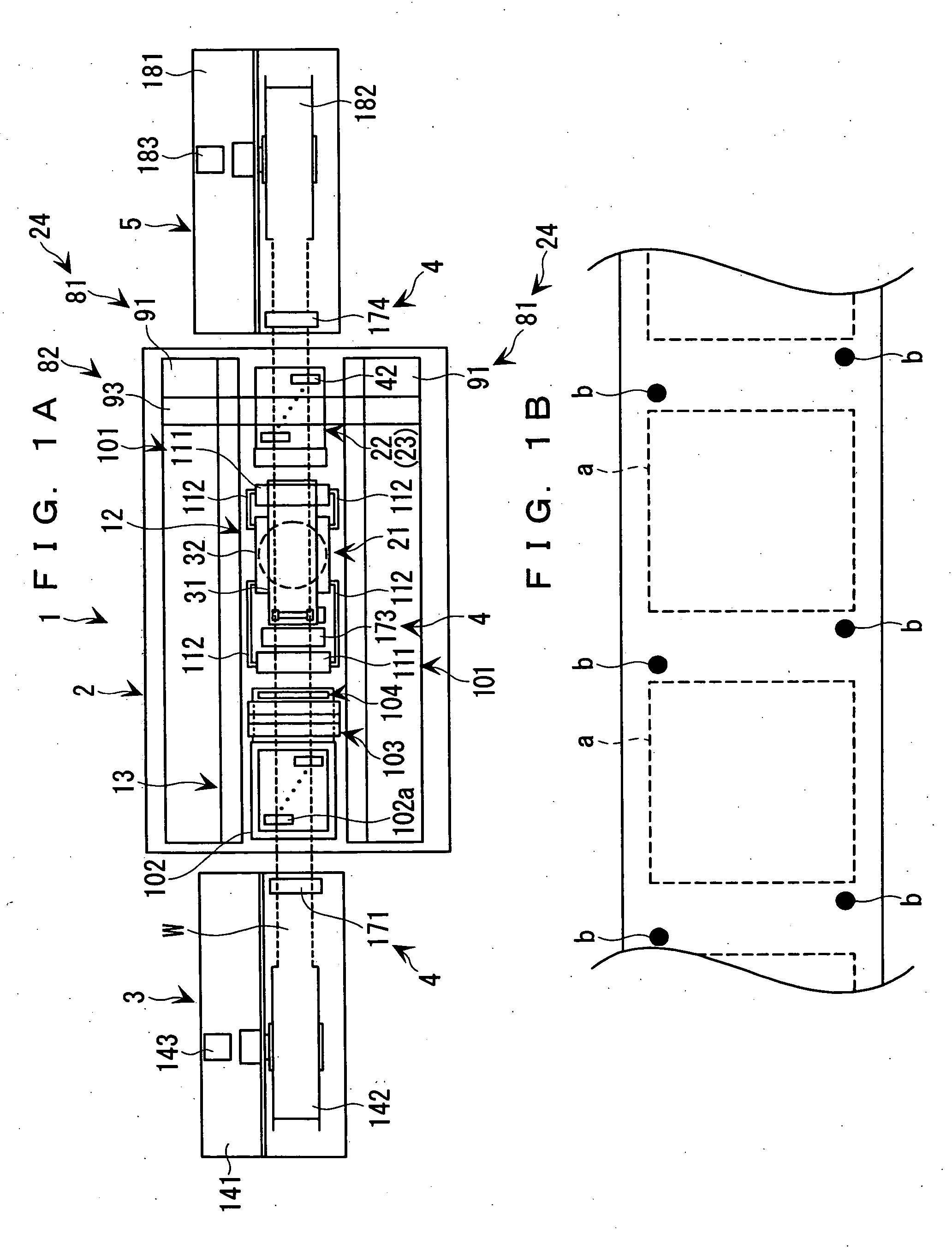

Apparatus for ejecting liquid droplet, work to be applied thereto, method of manufacturing electro-optic device, electro-optic device, and electronic equipment

InactiveUS20060088700A1Stable drawingHigh precisionDecorative surface effectsTypewritersEngineeringWorking set

Owner:SEIKO EPSON CORP

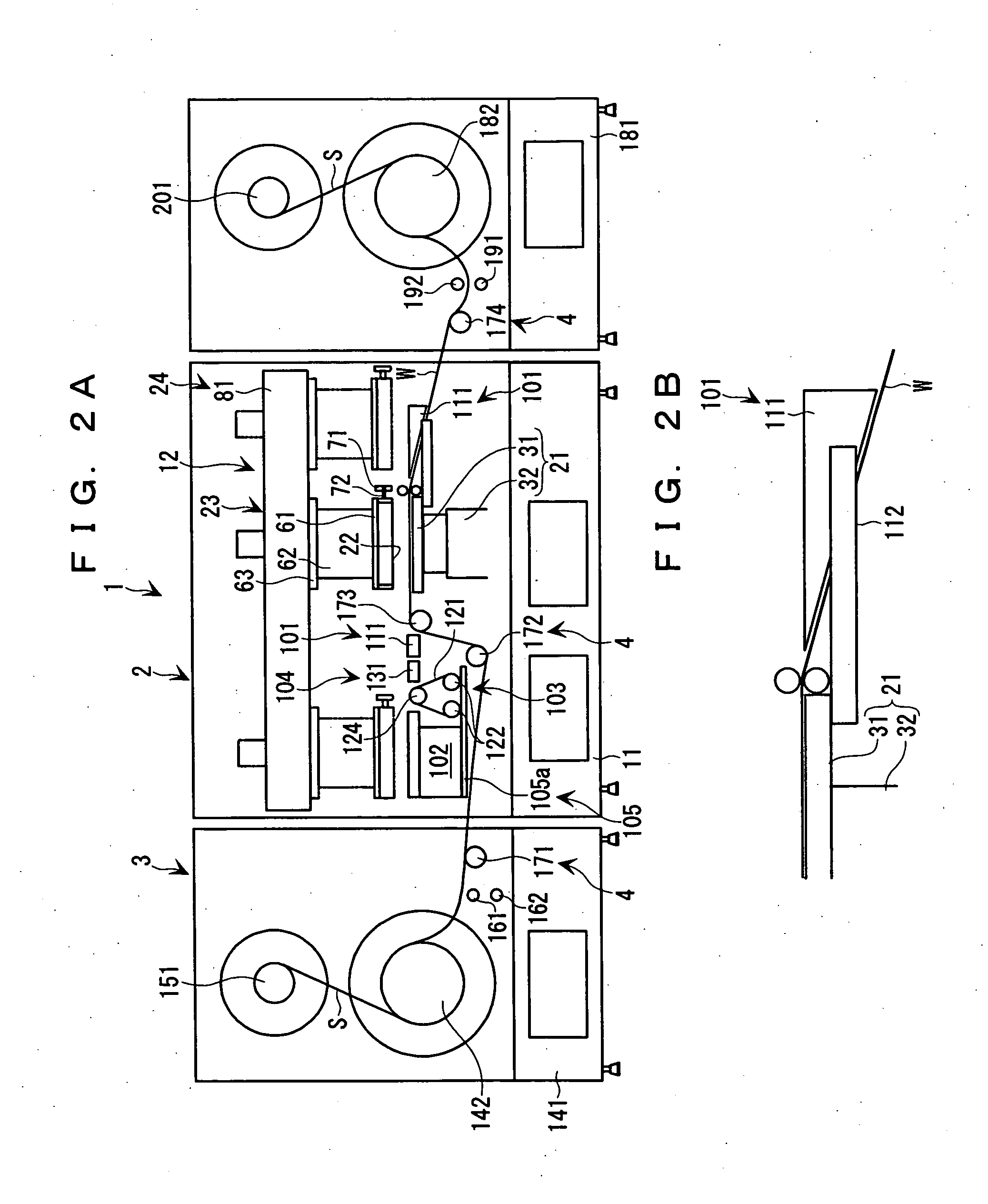

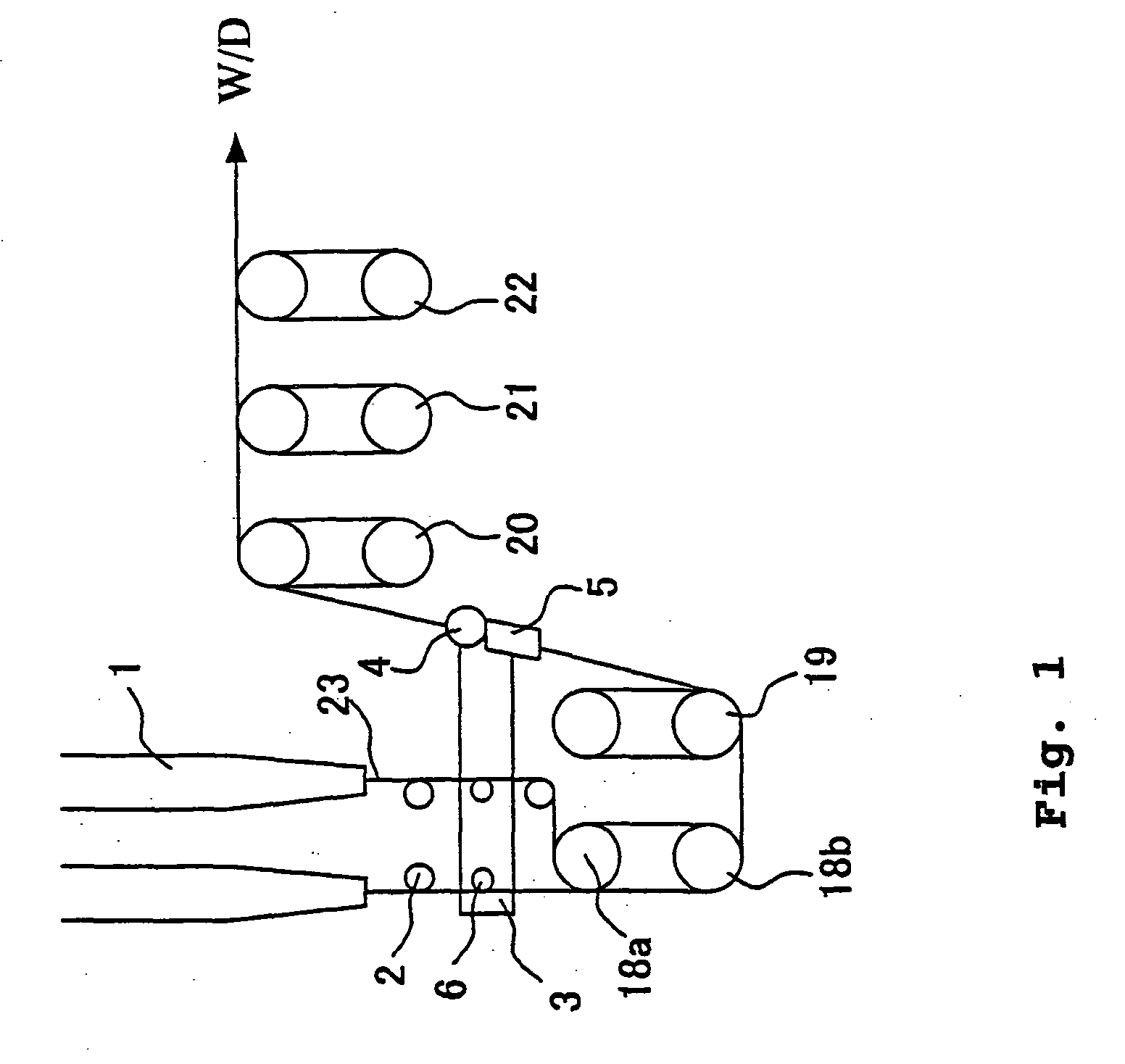

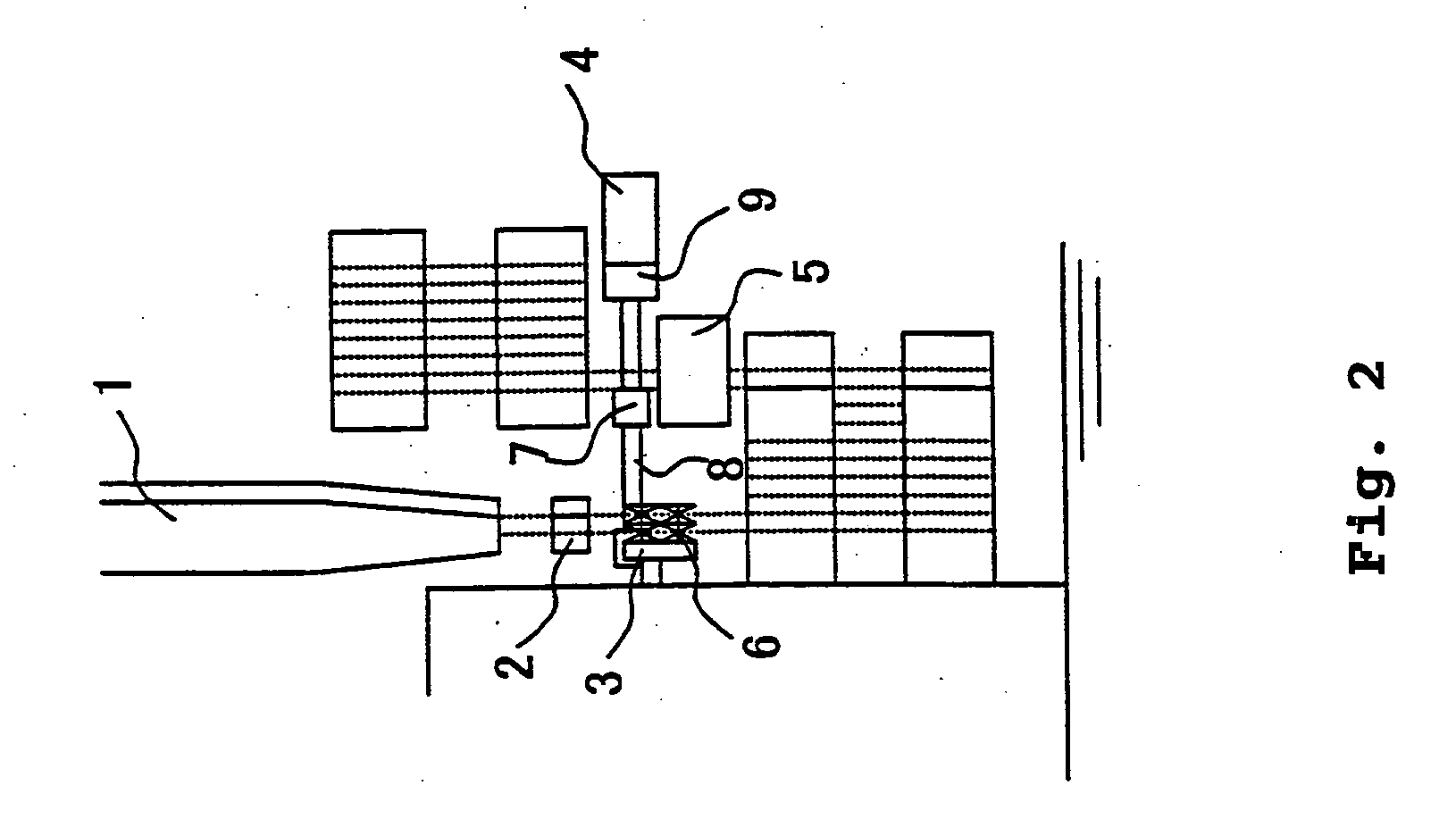

Production method of synthetic and yarn traverse device

InactiveUS20040012115A1Avoid separationIncrease volumeArtificial filament heat treatmentStretch-spinning methodsYarnReciprocating motion

In the process of drawing / heat treating synthetic fiber thread melted and spun via a plurality of godet rollers and subsequently winding the same, accumulation of extraneous matter on the surface of the godet rollers may be prevented by performing multistage drawing / heat treatment while reciprocating the thread in the direction of the axis of rotation of the godet roller using the godet rollers at least two of which have surfaces having the roughness of 0.5<=Ra<=5 and one of which has a surface at a temperature of at least (melting point of synthetic fiber-70° C.), whereby occurrence of thread breakage or generation of fuzz may be prevented and synthetic fiber whereof the rate of operation can be increased and efficiency of manufacture is improved may be obtained.

Owner:TORAY IND INC

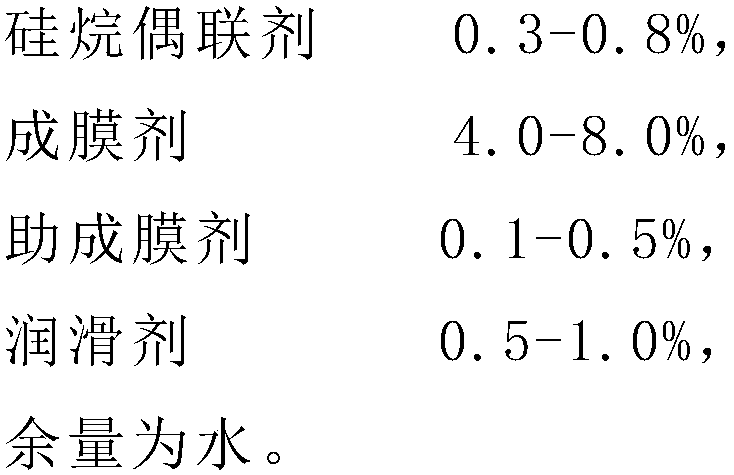

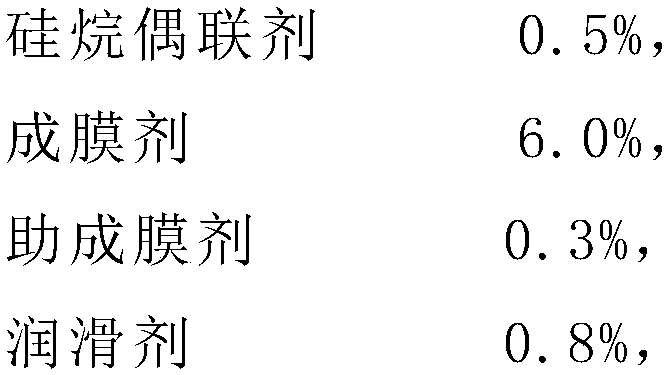

Basalt fibers applied to epoxy prepreg and production method of basalt fibers

The invention provides basalt fibers applied to an epoxy prepreg and a production method of the basalt fibers, and belongs to the technical field of fiber production. The production method comprises the following steps: A, pretreatment: grinding basalt ores into basalt ore powder for standby application, and during feeding of a furnace stage, adding a certain quantity of the basalt ore powder at regular intervals, so that the basalt ore powder added per hour corresponds to a flow of a leakage plate; B, wire drawing: setting the flow of the leakage plate to correspond to yield of the furnace stage to obtain the basalt fibers; C, immersion: immersing the basalt fibers obtained in the step B with an immersion agent; D, yarn drying: adopting a temperature curve to bake the immersed basalt fibers to enable the immersion agent to be adhered to the surfaces of the basalt fibers thoroughly; and E, winding: enabling a plurality of basalt fibers to be stranded. The basalt fibers provided by theinvention can be rapidly combined with epoxy resin, and also have good wire drawing performance, winding performance, weaving performance and stable linear density.

Owner:ZHEJIANG GBF BASALT FIBER

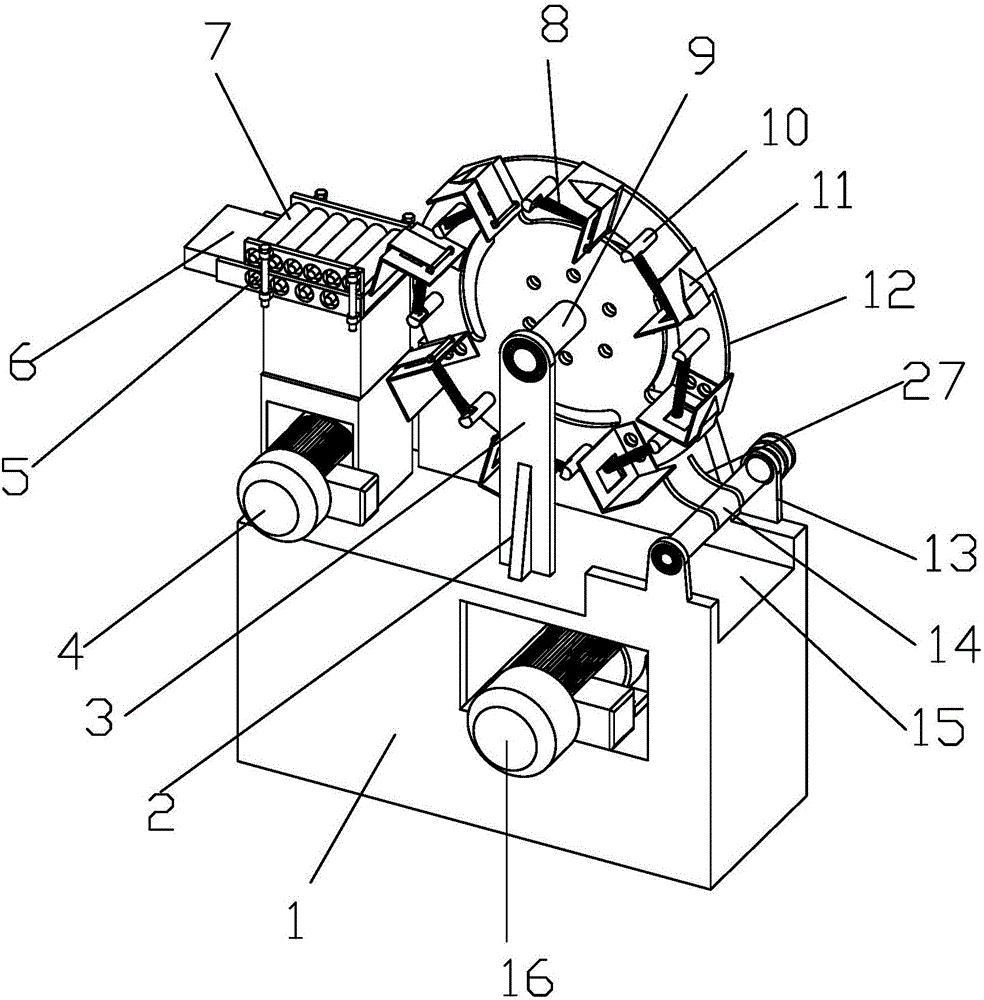

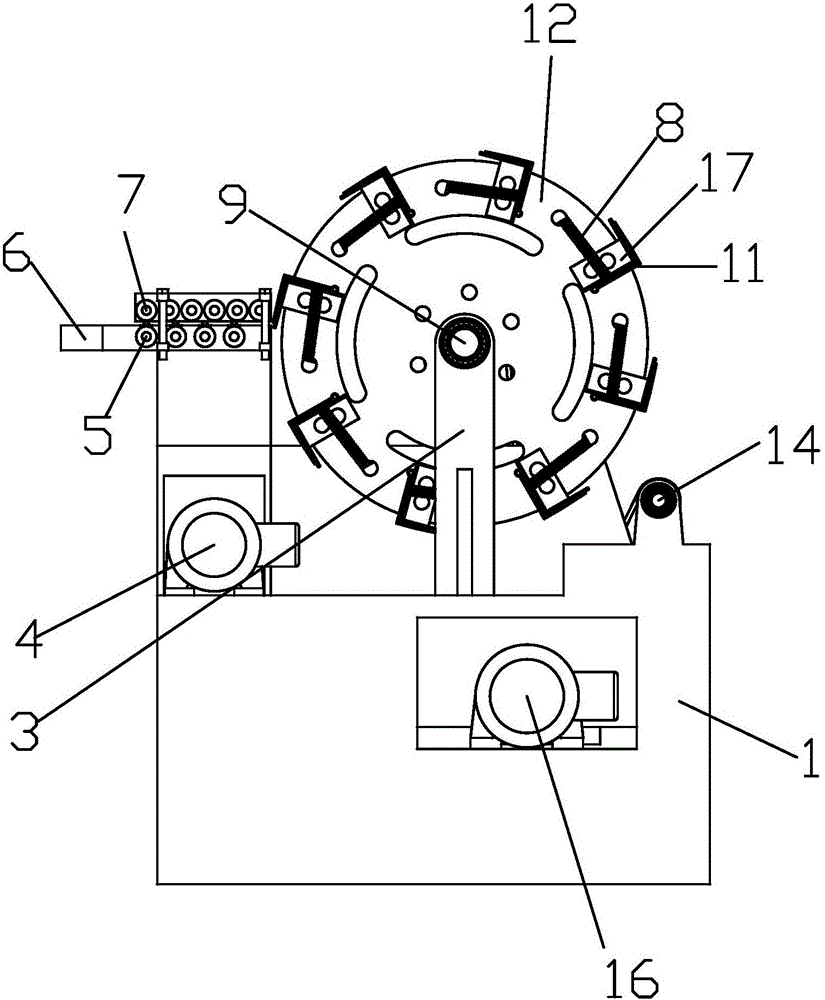

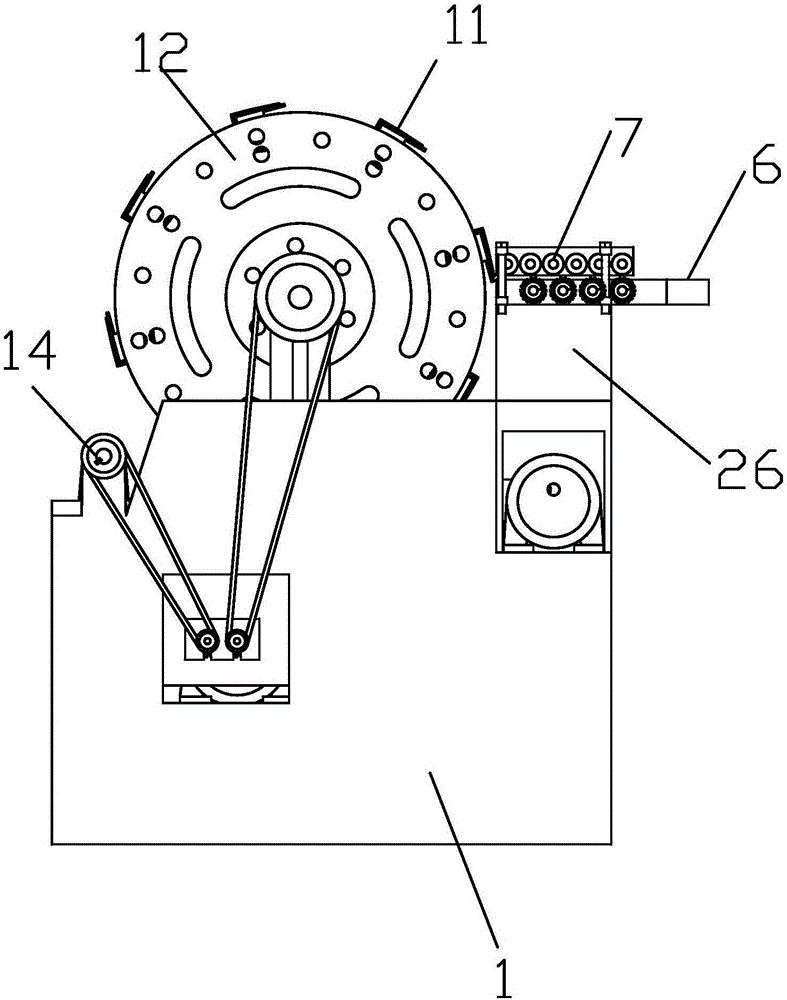

Shredded squid drawing machine and drawing method thereof

The invention relates to a shredded squid drawing machine which comprises a base, wherein a feeding hole is formed in one end of the base and is connected with a transmission mechanism; a drawing mechanism is arranged on the base; the drawing mechanism comprises first brackets which are oppositely arranged on the base; a first rotating shaft capable of rotating to the direction of the transmission mechanism is arranged between the first brackets; a rotating disc is arranged on the first rotating shaft; a cutter chassis is annularly arranged on the rotating disc at intervals; a drawing knife is arranged on the cutter chassis; the outlet end of the transmission mechanism is close to the cutter point of the drawing knife; and a discharging hole is formed in one end, which is far away from the feeding hole, of the base. The drawing mechanism is composed of the drawing knife and the cutter chassis, the drawing length is increased, the drawing process is stable, and the shredded squid is difficult to break; the squid does not need to be pre-pressed by a roller with teeth, and is rolled by a compression roller of a polish rod, so that organ-shaped break marks are formed on the squid body according to squid lines, and the shredded squid is difficult to break; the drawing width is not limited by the tooth width of the roller; and the rod speed is controlled by an adjustable-speed motor, and the transmission speed can be adjusted according to needs.

Owner:SHANDONG UNIV

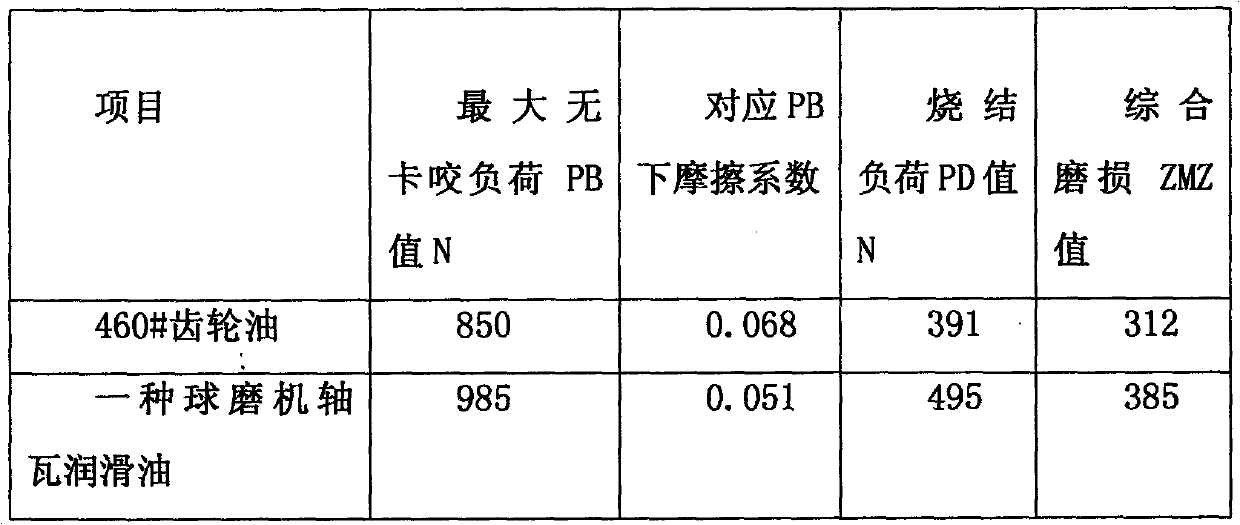

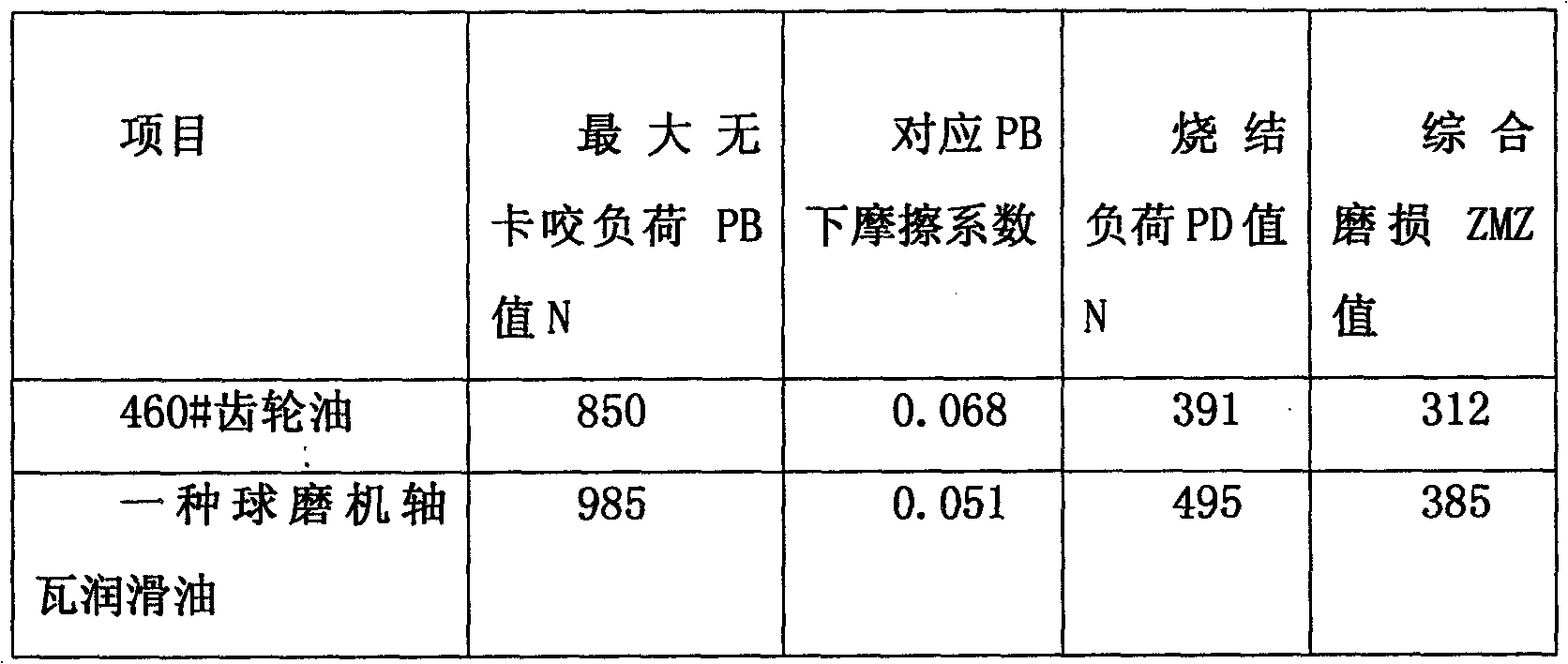

Ball grinding mill bearing bush lubricating oil and manufacturing method thereof

ActiveCN102559347AImprove the lubrication effectReduce the temperatureBase-materialsPolyesterEngineering

Ball grinding mill bearing bush lubricating oil and a manufacturing method thereof solve the problem that a ball grinding mill bearing bush is poor in lubrication in the severe environment. The ball grinding mill bearing bush lubricating oil is formed by using synthetic oil as base oil and refining multiple added efficient composite additives, has the advantages of being abrasion-resisting, high-temperature-resisting, oxidation-resisting, firm in formed film and the like, and can repair wire drawing and reduce abrasion and bearing bush temperature at fastest speed. The work efficiency and the product quality are improved obviously, the repair and maintenance costs are reduced, the service life of a device is prolonged, and energy consumption is reduced greatly. The ball grinding mill bearing bush lubricating oil is composed of, by mass, mineral lubricating oil 49%-69%, polyester synthetic oil 20%-40%, thickening agent 0.05%-0.15%, organic molybdenum composite additive 2.5%-4.5%, T306 additive 1%-3%, T202 antioxygen 0.4%-0.6%, T551 metal deactivator 0.7%-0.9% and T704 antirust additive 0.6%-0.8%, wherein the summation of the components is a hundred percent.

Owner:洛阳正本润滑材料有限公司

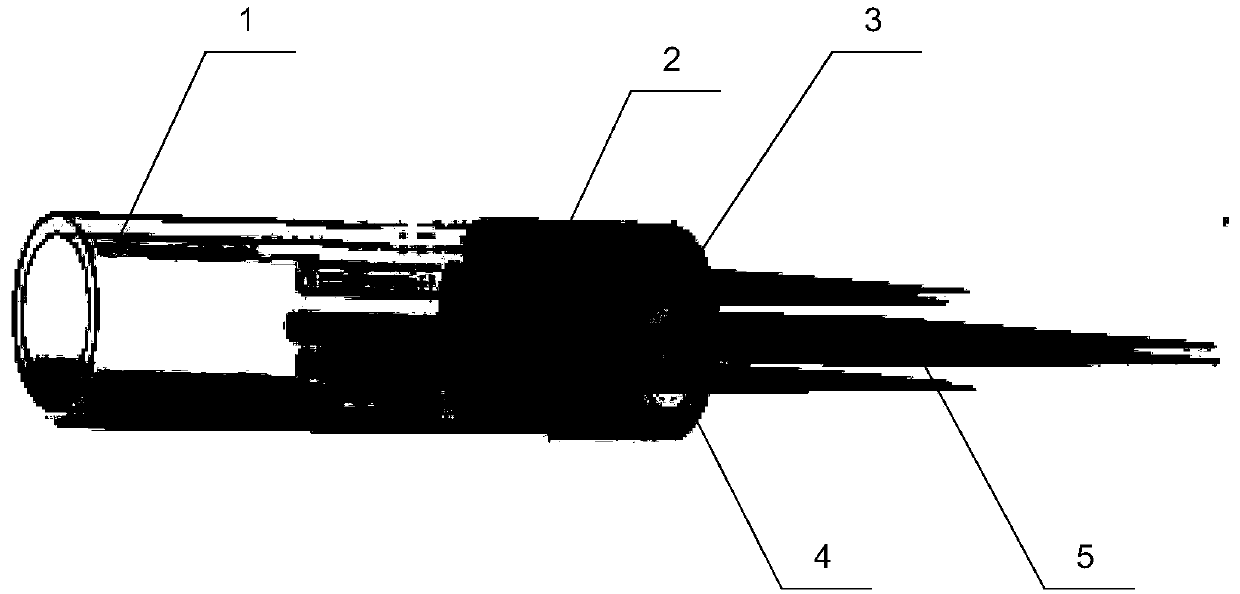

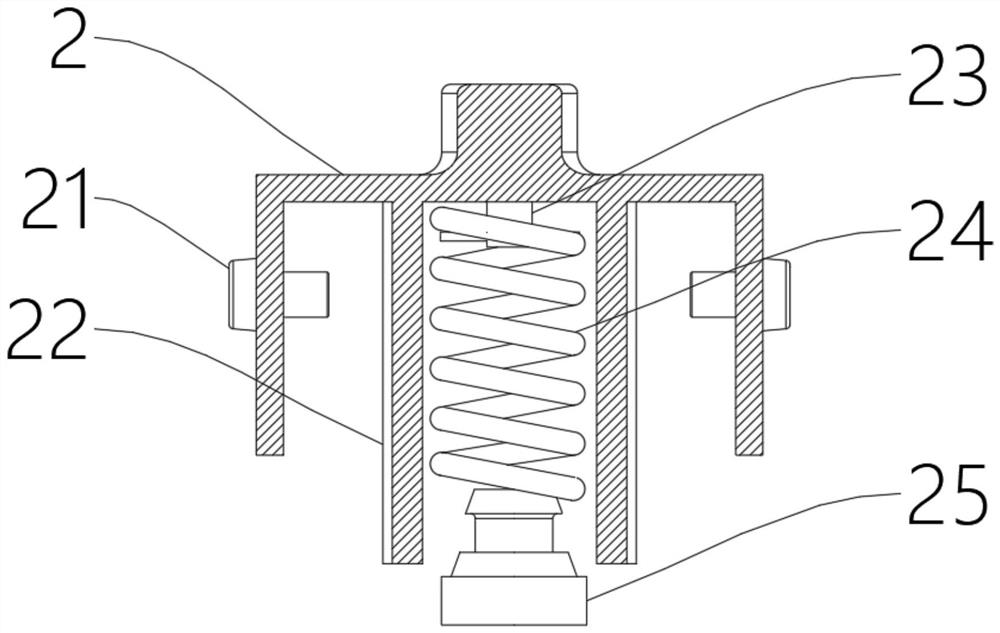

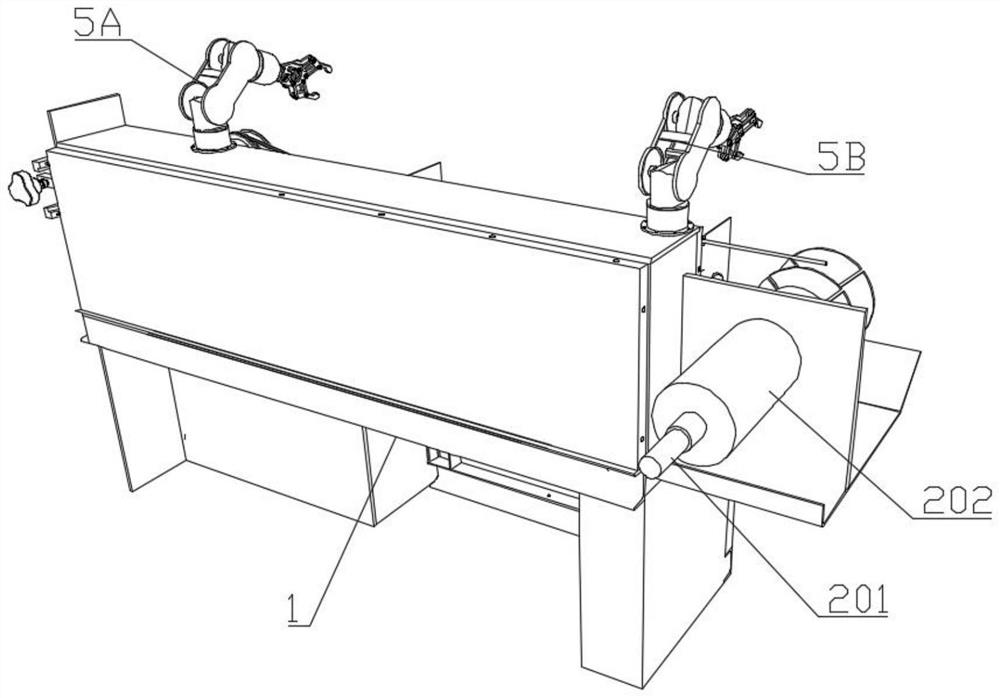

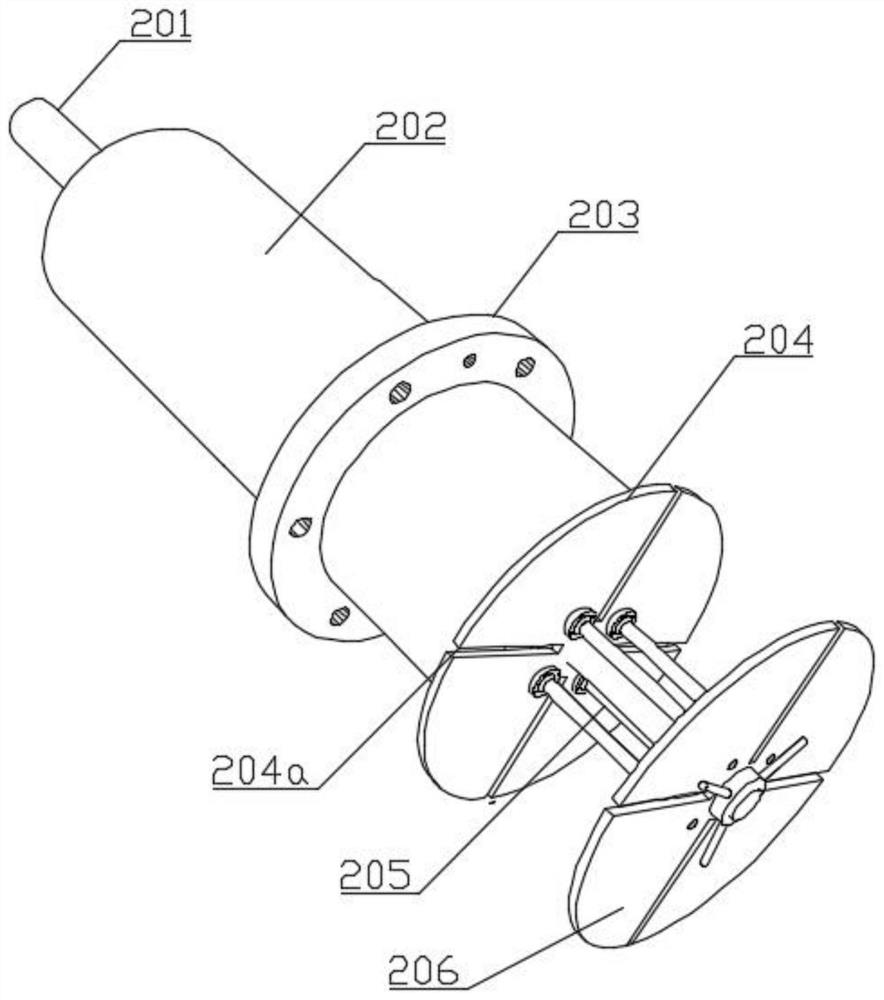

Wire drawing device and method for reducing surface defects of optical fiber

ActiveCN111410417AStable drawingNo slippageGlass making apparatusGlass productionFiber diameterMaterials science

The invention discloses a wire drawing device and method for reducing surface defects of an optical fiber. The wire drawing device comprises a wire drawing mechanism, the wire drawing mechanism comprises a clamping jaw and a mechanical arm capable of moving up and down, one end of the mechanical arm is connected with the clamping jaw, and the clamping jaw is used for clamping the optical fiber fortraction drawing. The drawing method comprises the following steps: (1) melting, drawing and drooping an optical fiber preform in an optical fiber drawing furnace to obtain an optical fiber filament,and clamping the optical fiber filament by a mechanical clamping jaw; (2) moving the displacement slide block, and moving the mechanical arm up and down to draw the optical fiber filament; and (3) carrying out fixed-length cutting on the dragged optical fiber through a cutter. The clamping jaws are in point contact with the optical fiber for traction and drawing, so that the drawing process of the optical fiber is more stable, surface contact and skin layer damage of the optical fiber in the drawing process are reduced, and the drawing surface quality of the optical fiber and the stability ofthe fiber diameter are improved.

Owner:CHINA BUILDING MATERIALS ACAD

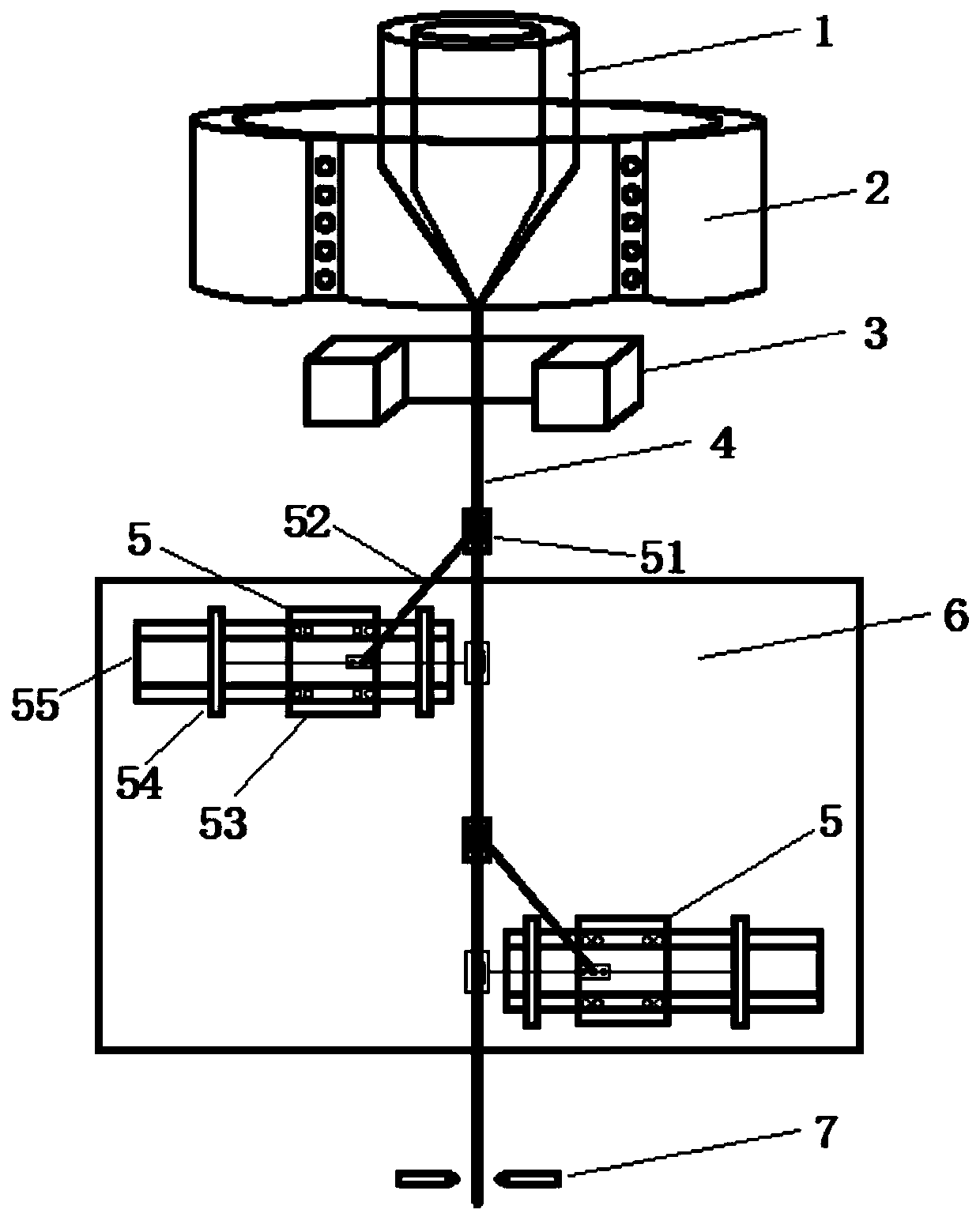

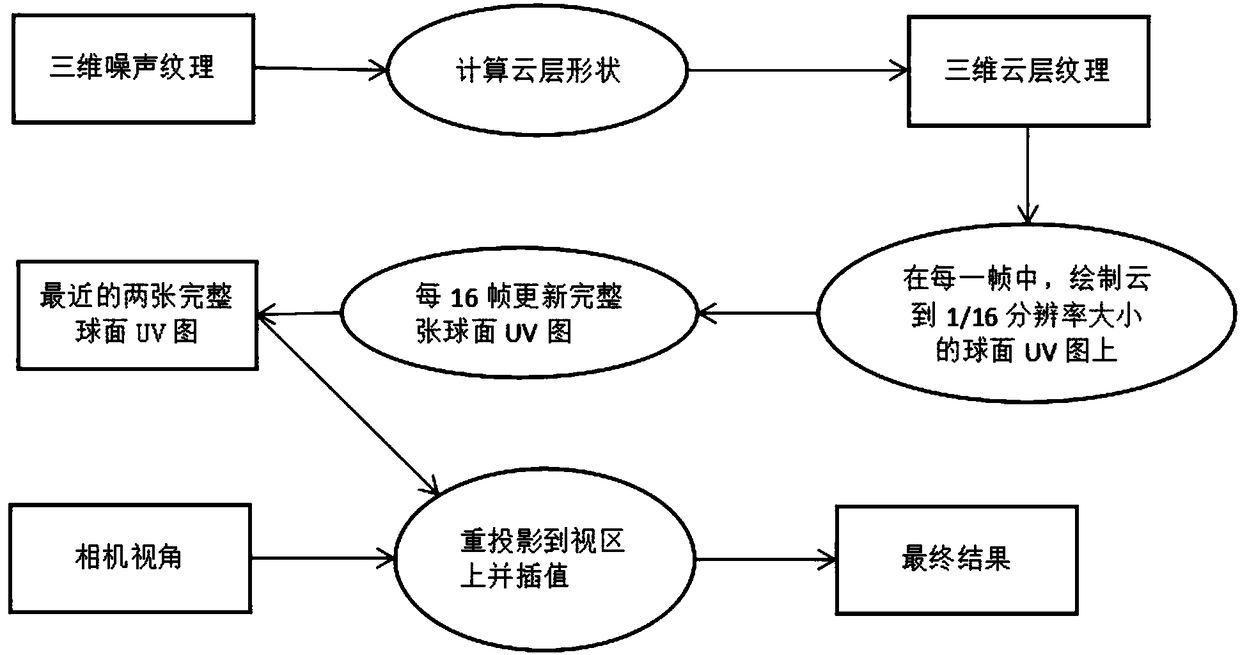

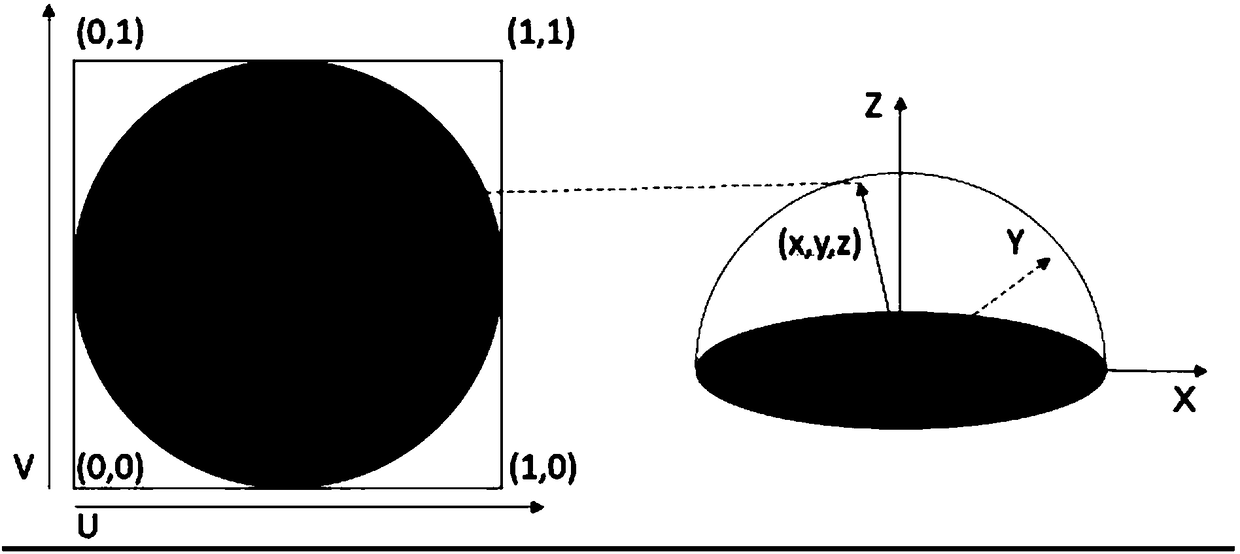

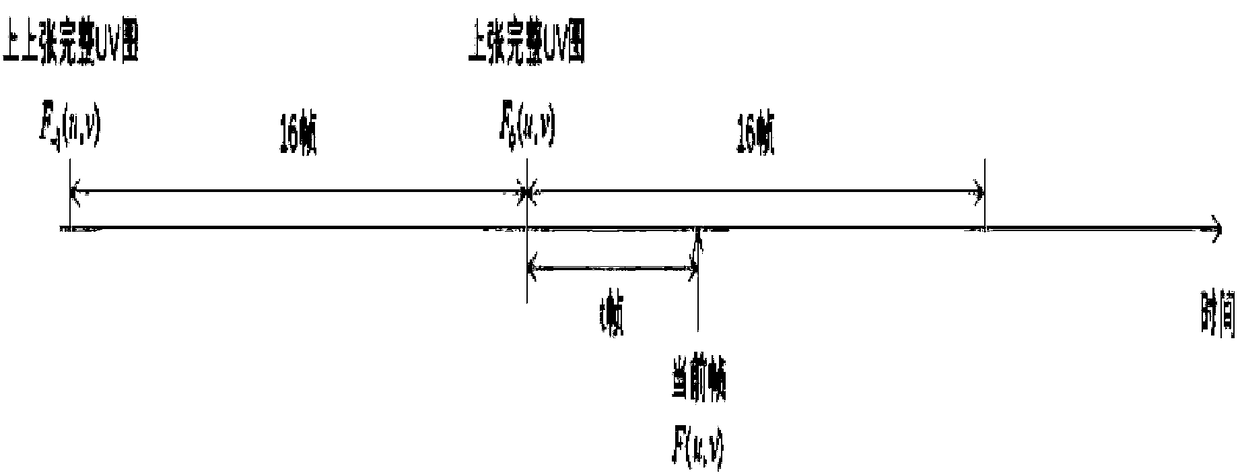

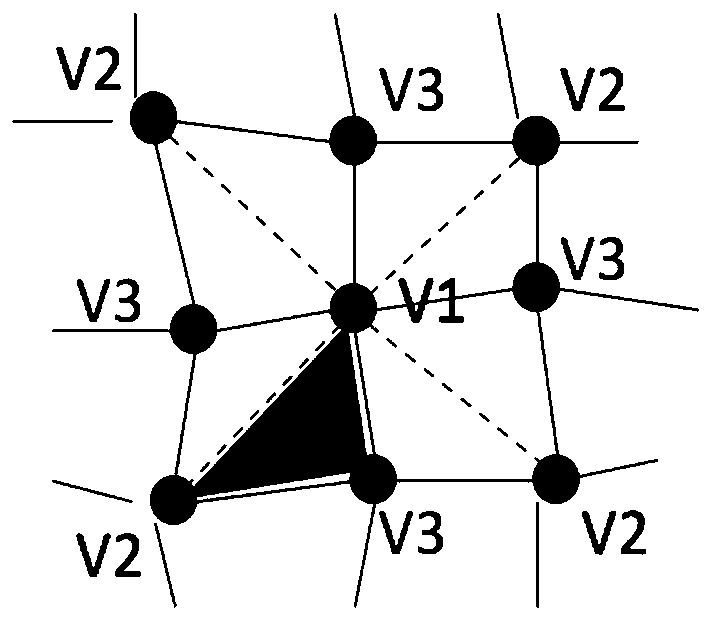

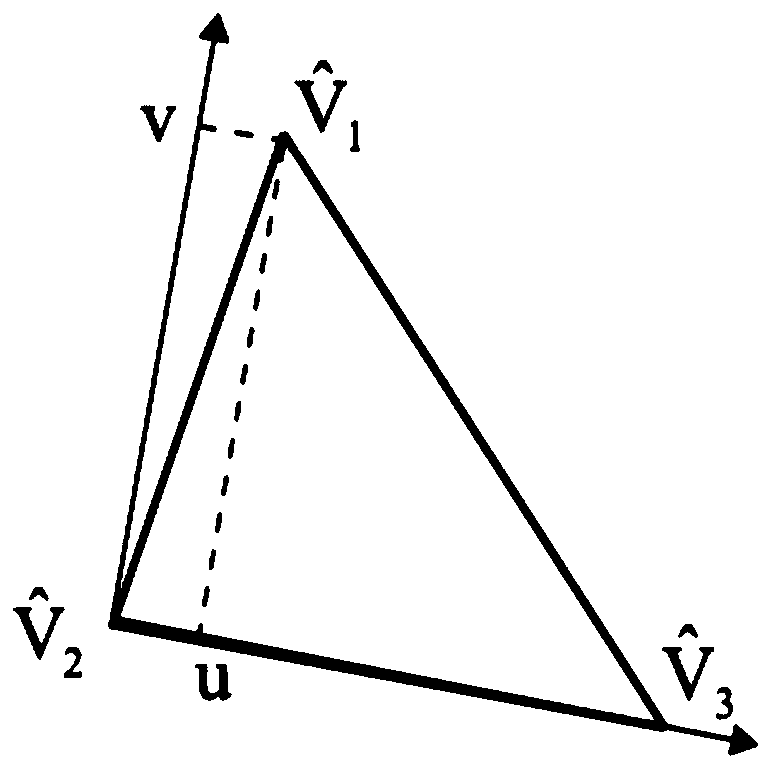

A cloud real-time rendering optimization algorithm based on spherical UV and reprojection

PendingCN109461197AStable drawing efficiency and qualityIntegrity guaranteed3D-image renderingReal-time renderingCamera angle

The invention discloses a cloud real-time rendering optimization algorithm based on spherical UV and re-projection, 3-D noise texture is used to compute cloud shape and generate 3-D cloud texture, thewhole sky hemisphere is parameterized by spherical UV, dividing the spherical UV space into small blocks of 4x4 pixels, In each frame, only one pixel cloud is drawn in the corresponding direction foreach small block, the whole spherical UV map is reserved after every 16 frames, and the two recently generated complete spherical UV maps are re-projected onto the viewing area according to the current camera angle of view and interpolated, so as to obtain the final rendering result. The invention solves the problem that the noise point occurs when the angle of view or the cloud layer changes rapidly.

Owner:北京五一视界数字孪生科技股份有限公司

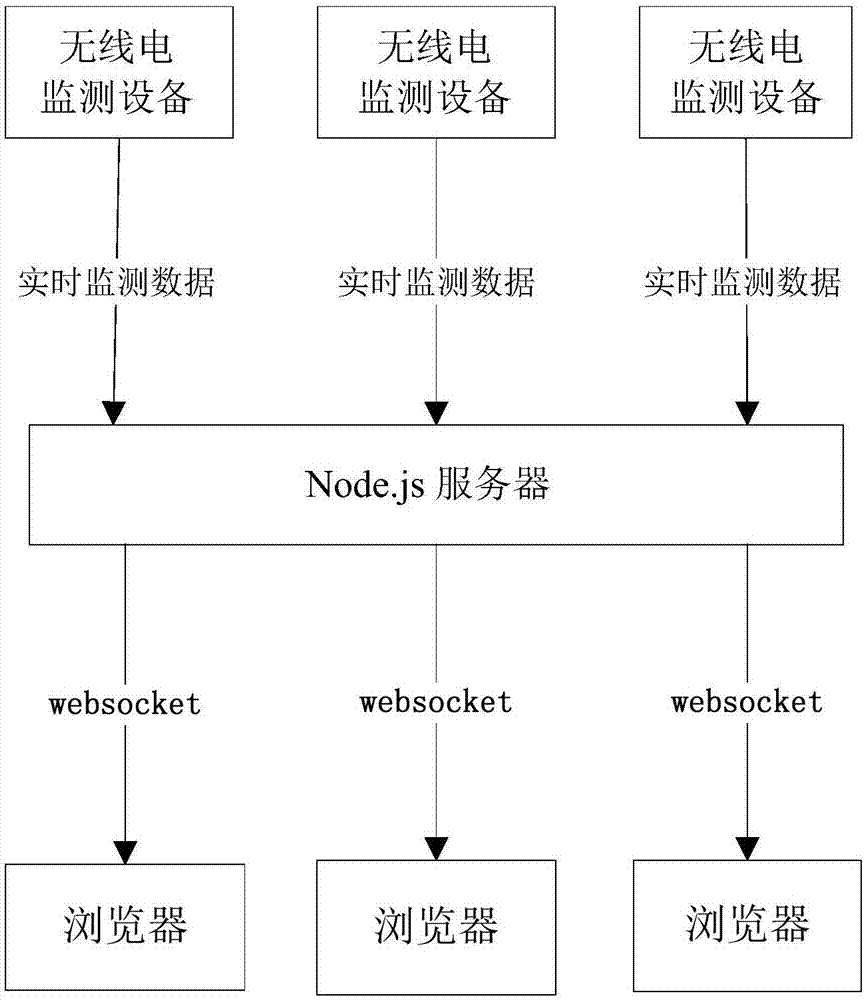

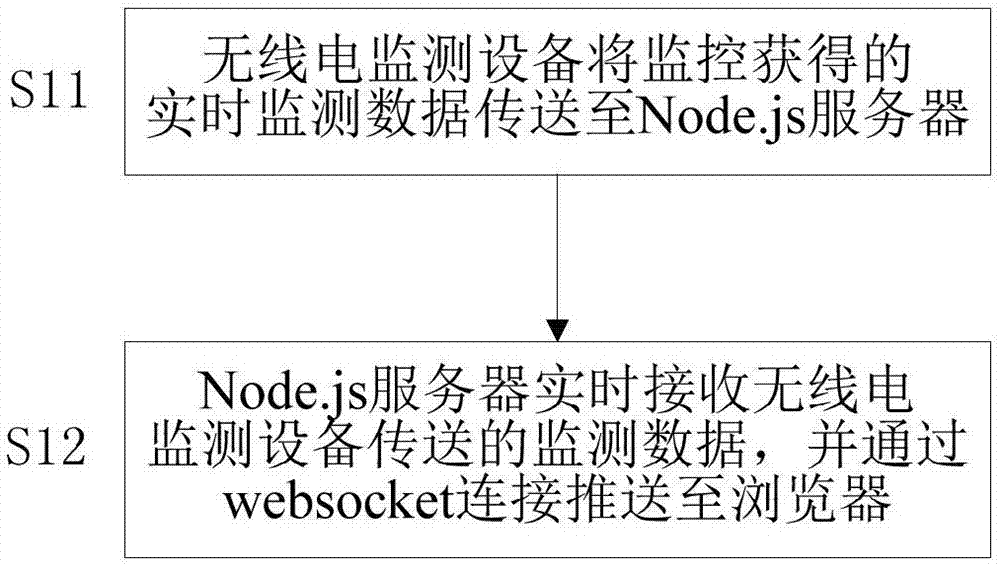

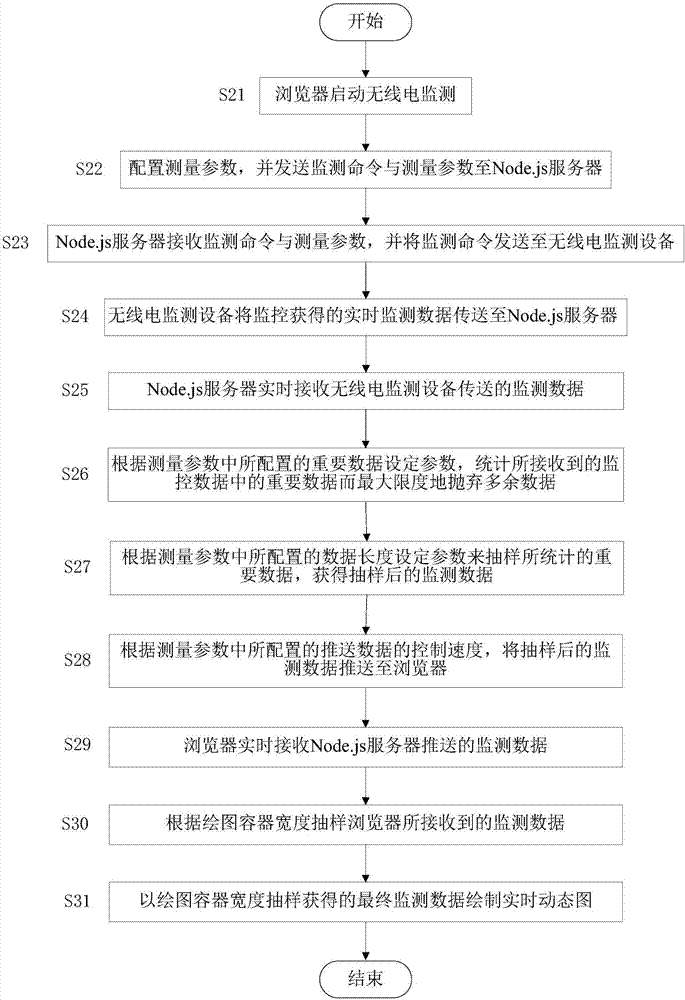

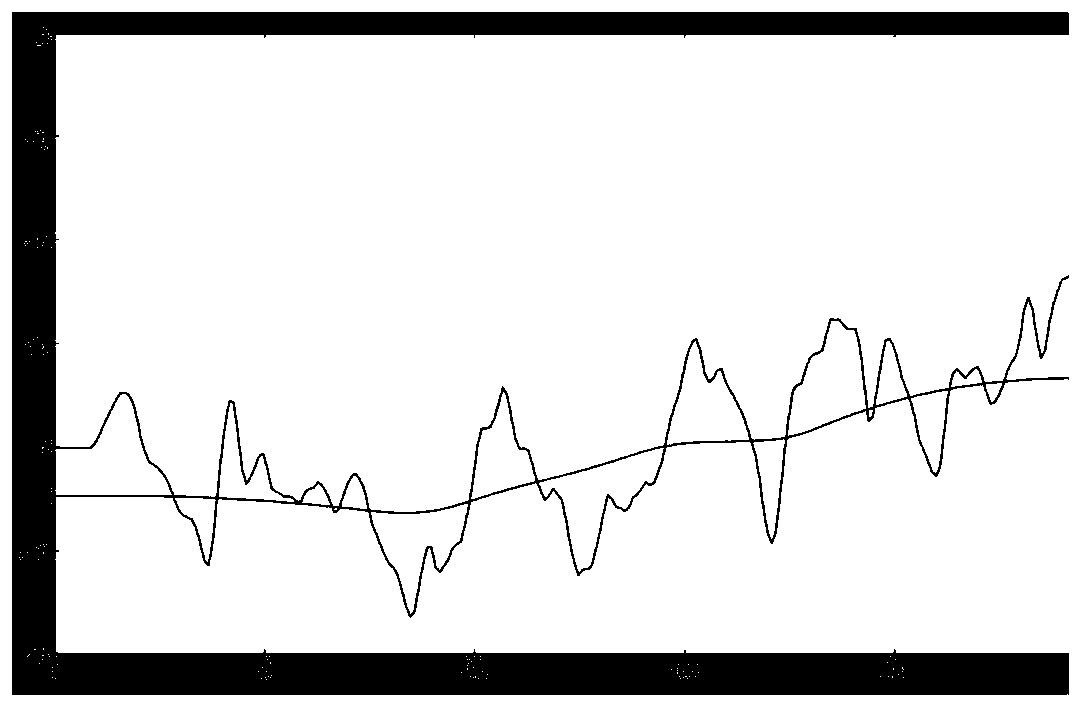

Radio monitoring data real-time push and dynamic graph drawing method

InactiveCN107395681AReal-time drawingStable drawingVisual/graphical programmingTransmissionWeb applicationWebSocket

The invention provides a radio monitoring data real-time push and dynamic graph drawing method. According to the radio monitoring data real-time push method, a radio monitoring device transmits real-time monitoring data obtained through monitoring to a Node.js server, wherein websocket connection is pre-established between the Node.js server and a browser; the Node.js server receives the monitoring data transmitted by the radio monitoring device in real time and pushes the monitoring data to a browser through the websocket connection; and the browser receives the monitoring data pushed by the Node.js server in real time and draws a radio monitoring data real-time dynamic graph through utilization of the received monitoring data. The methods are applicable to a Web application system, and the method can be used for carrying out radio monitoring data real-time push and dynamic graph drawing at a client only depending on an operation environment of the browser, without installing any plug-in.

Owner:SHENZHEN RONGXING IND DEV CO LTD

A video jitter removing method based on a fusion motion model

ActiveCN109729263AStable drawingImprove viewing experienceTelevision system detailsColor television detailsPoint cloudGrid based

The invention discloses a video jitter removal method based on a fusion motion model, and the method comprises the following steps: (1) calculating an optical flow between adjacent frames of a video,extracting feature points, and calculating a matching result; (2) performing three-dimensional reconstruction according to the matching result of the feature points, and recovering the three-dimensional camera pose of the camera and the three-dimensional point cloud of the scene; (3) establishing a grid-based two-dimensional motion model by the optical flow, and describing a deformation relationship between the two frames; (4) smoothing the motion estimation of the three-dimensional motion model, and solving the motion compensation of the grid model; (5) smoothly calculating a motion track based on the grid model, and solving motion compensation; And (6) drawing a stable image frame according to the obtained motion compensation. According to the method, the three-dimensional motion model and the two-dimensional motion model are fused, the visual effect and robustness of the video jitter removal algorithm are improved, the motion track is smoothed by using an optimization method, motioncompensation is solved, the video content is stabilized, and the watching experience is optimized.

Owner:苏州中科广视文化科技有限公司

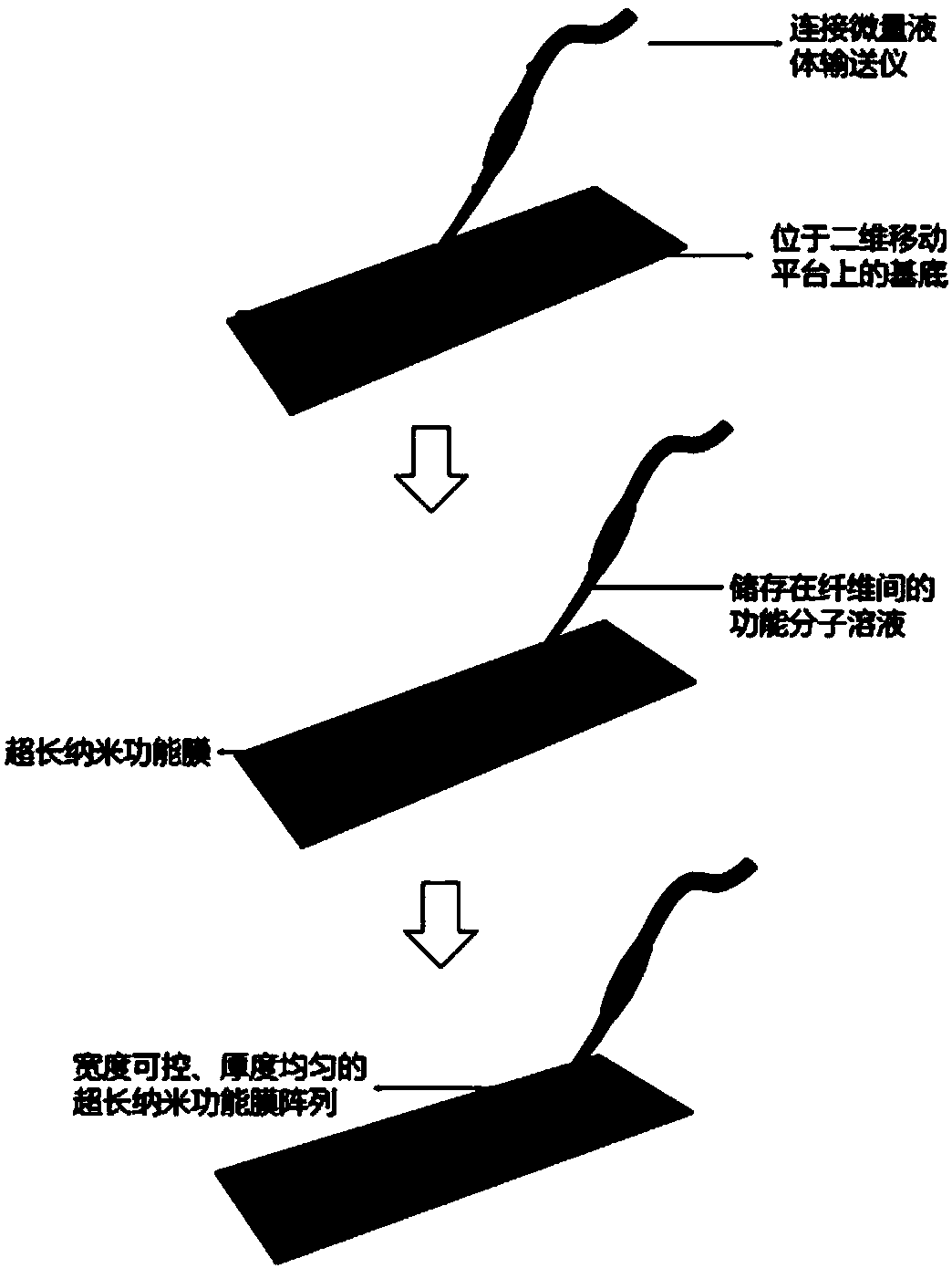

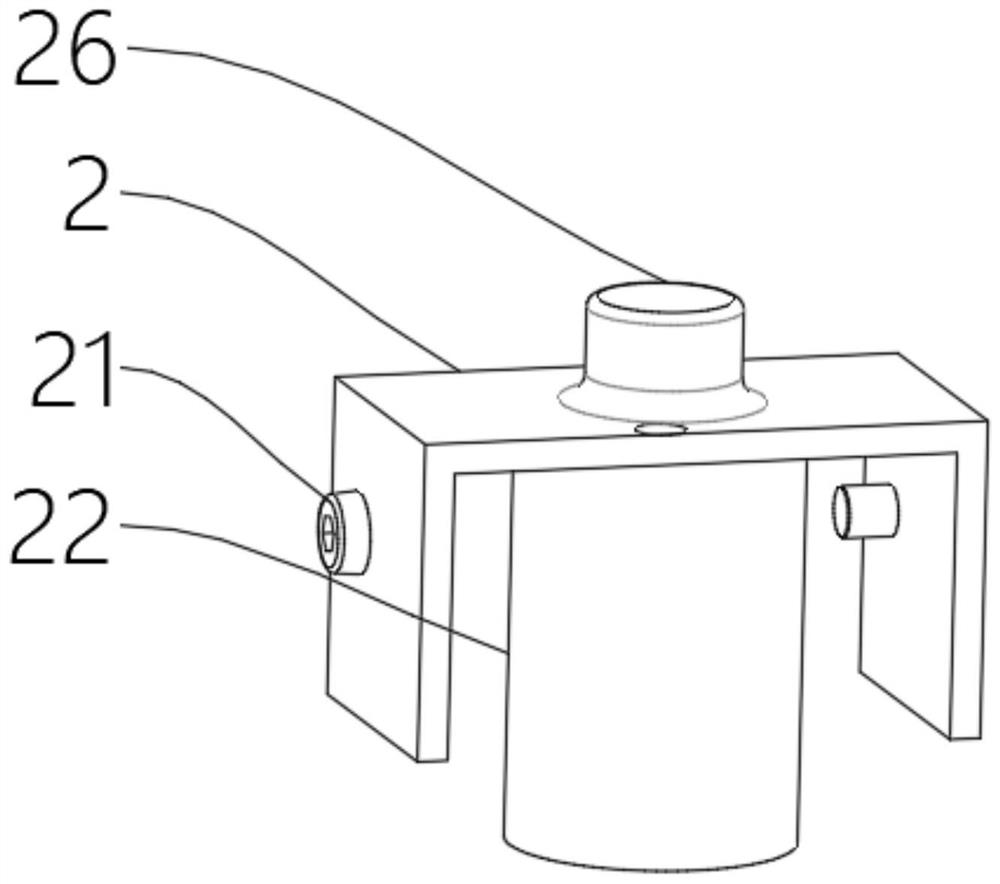

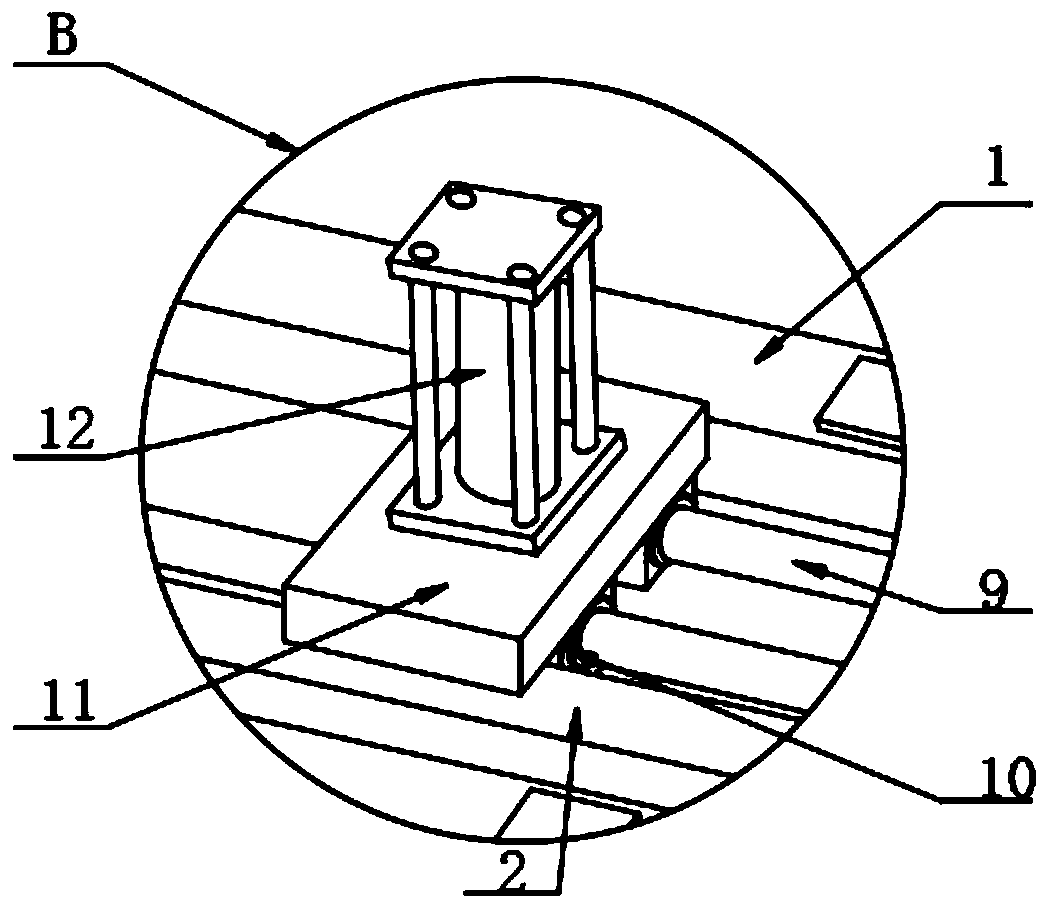

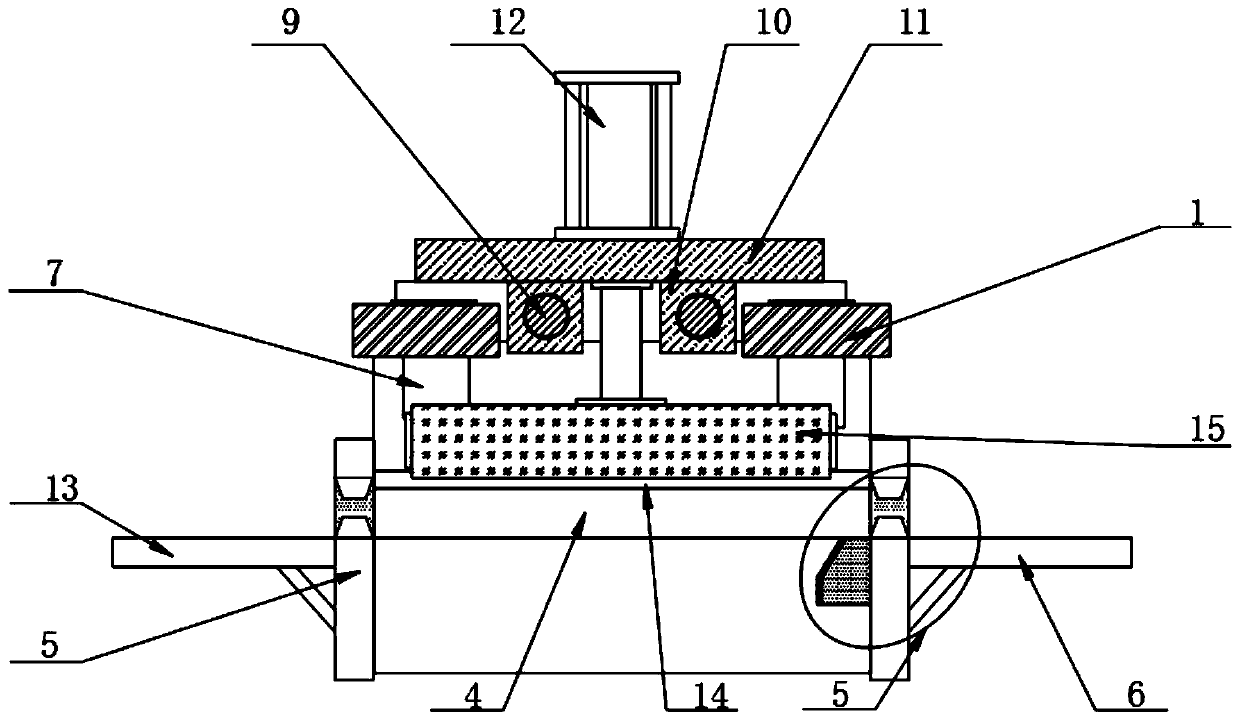

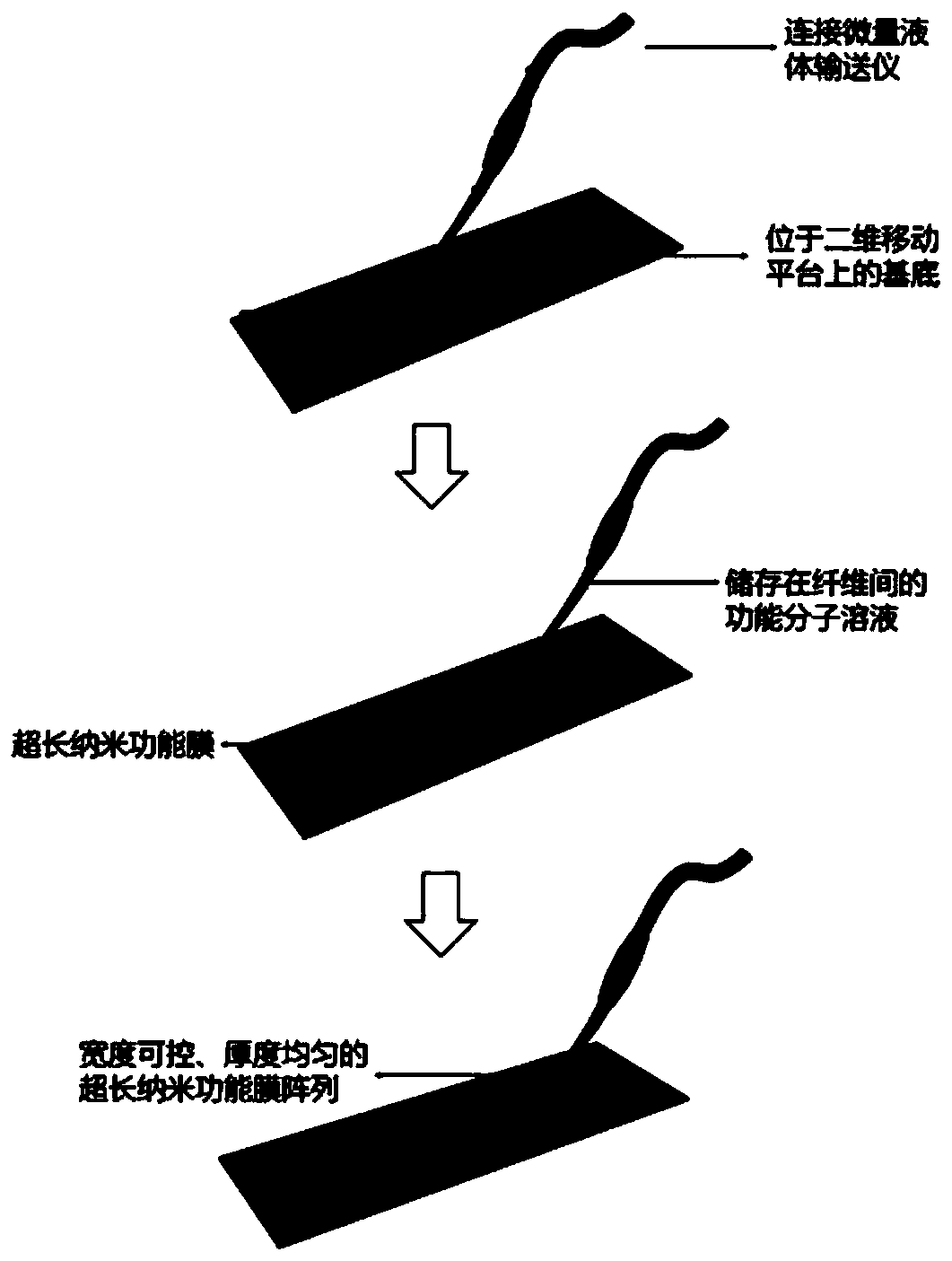

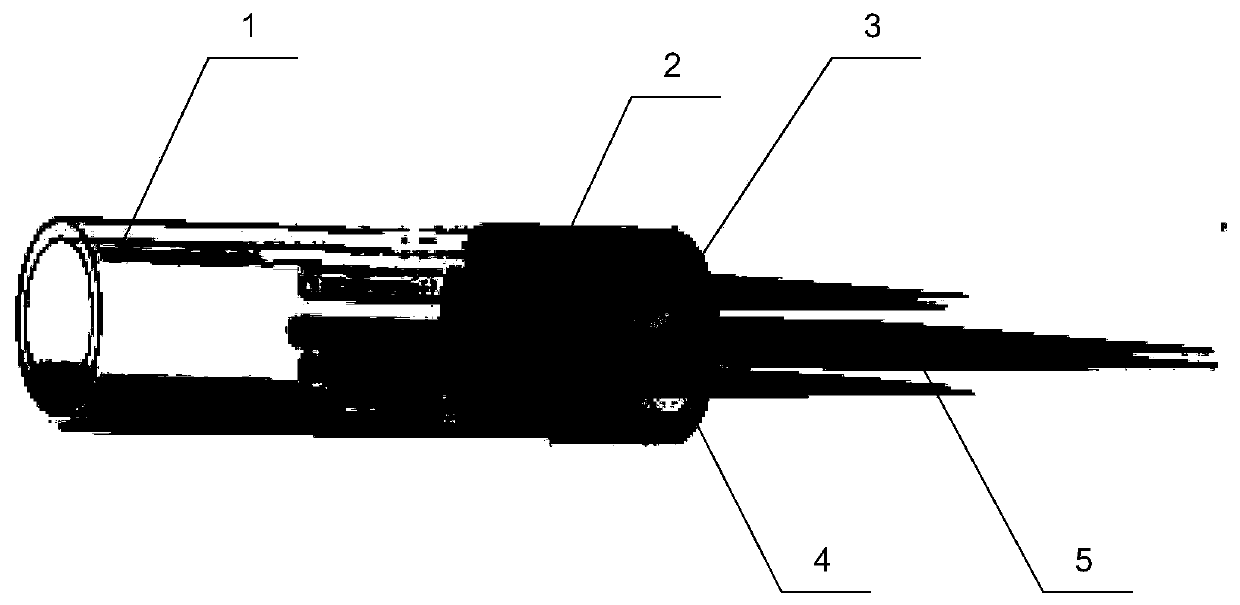

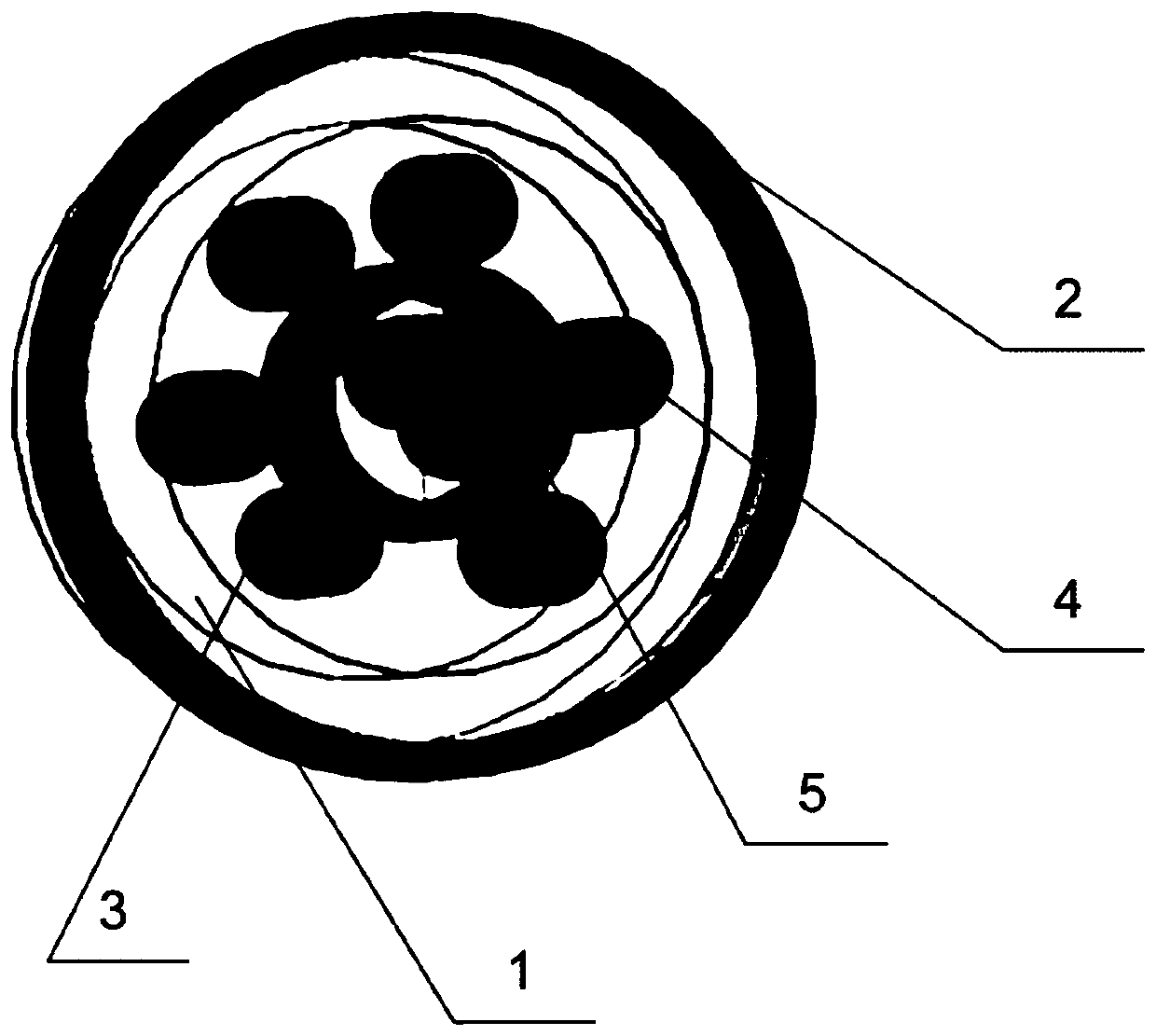

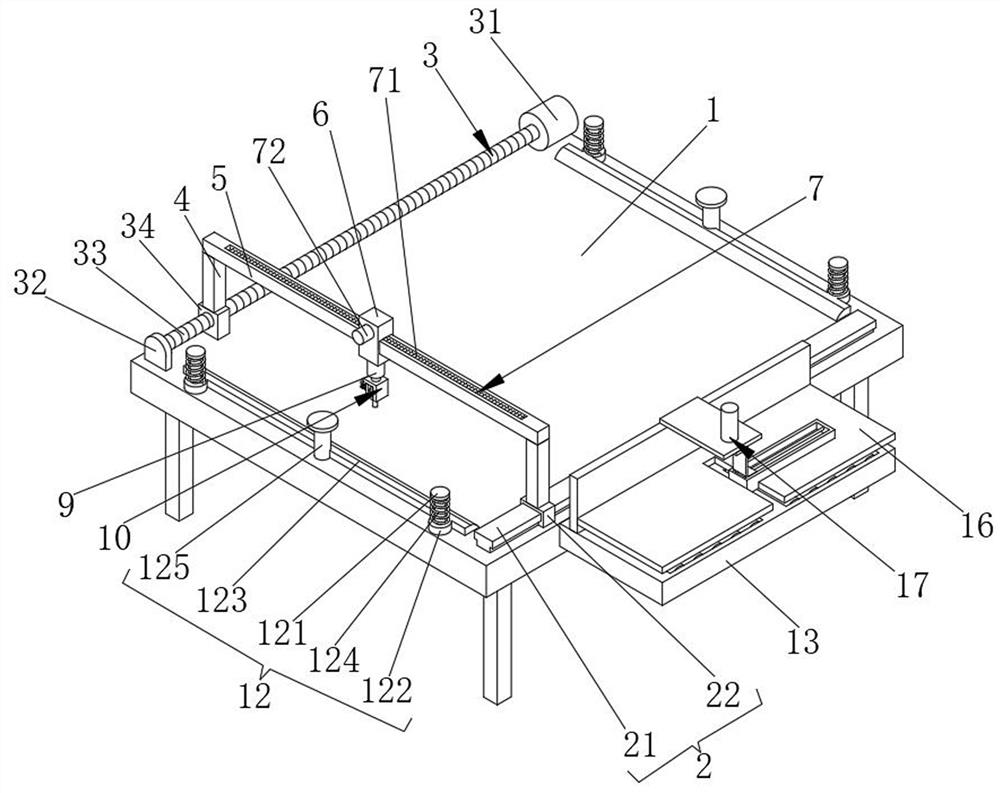

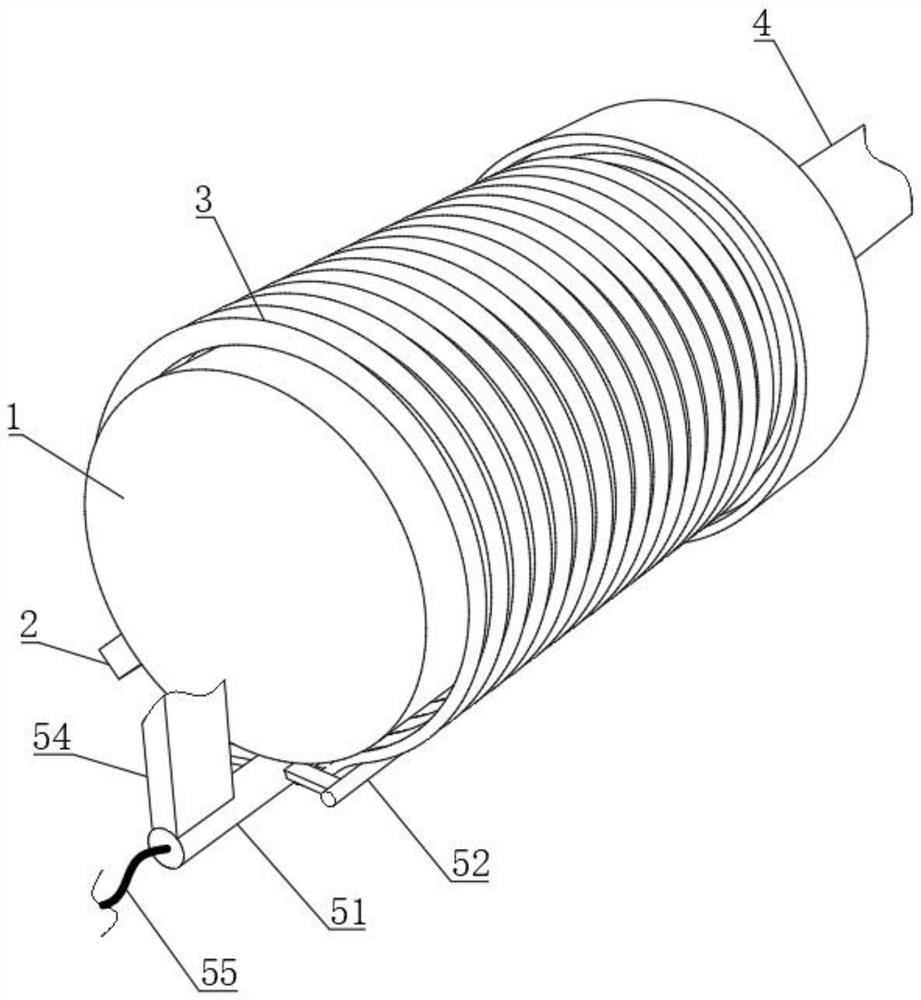

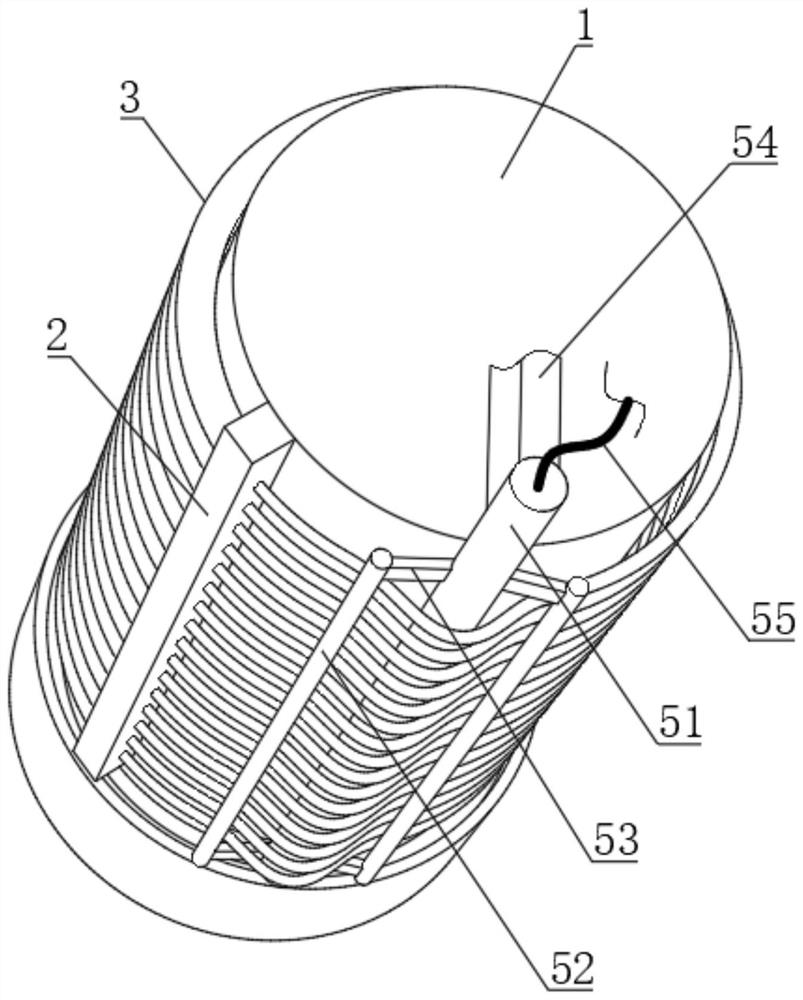

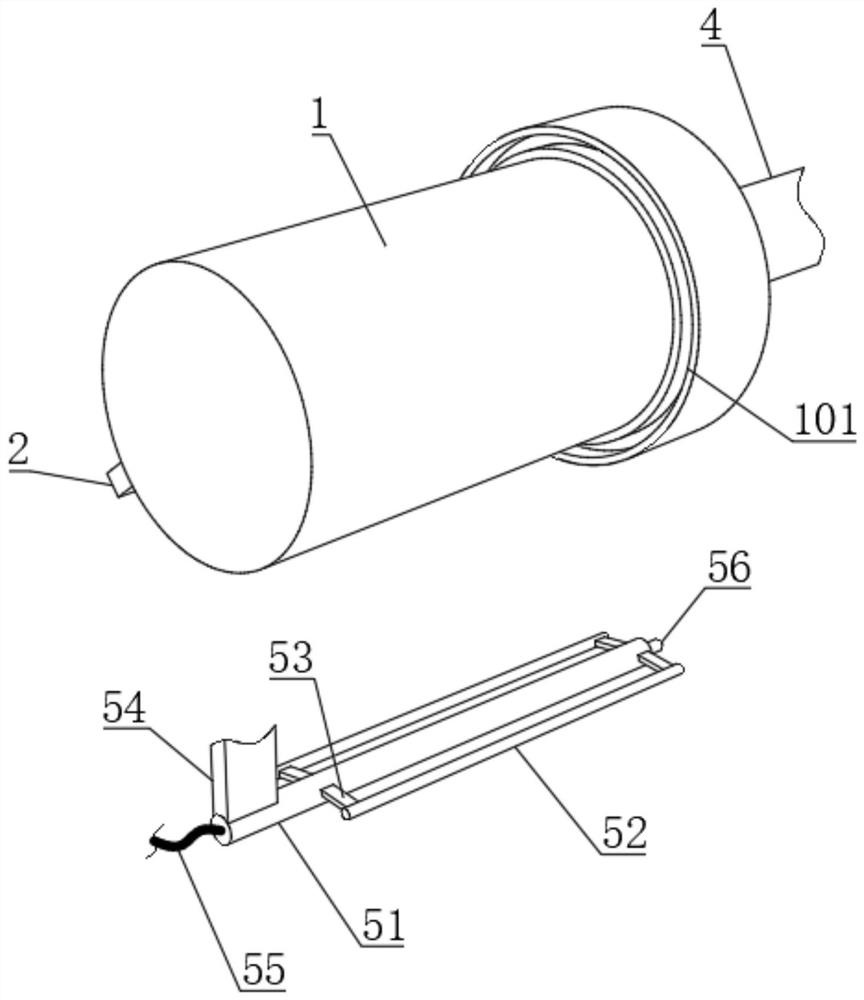

Brush printing film making device and nano film printing method based on the same

ActiveCN109693329AGuaranteed uniformityImprove adaptabilityNanostructure manufactureFlat articlesBrush deviceEngineering

The invention discloses a brush printing film making device and a nano film printing method based on the same. The brush printing film making device includes a brush device. The brush device includesan outer liquid supply pipe (1), a fastening pipe (2) and an inner liquid supply pipe (3). Several protruding pen hair (5) is fixedly arranged on the inner wall of the inner liquid supply pipe (3). The several protruding pen hair (5) is divided into two parts. Each part is arranged on each of the opposite inner walls of the inner liquid supply pipe (3), and the tip ends of the two protruding pen hair parts intersect and converge. A loop of liquid storage hair (4) is fixedly arranged on the outer wall of the inner liquid supply pipe (3) and around the inner liquid supply pipe. The outer liquidsupply pipe (1) sleeves the liquid storage hair (4). The fastening pipe (2) sleeves the outer liquid supply pipe (1). The outer liquid supply pipe and the inner liquid supply pipe fixed with the liquid storage hair and protruding pen hair are fixed by the fastening pipe, and so the protruding pen hair and the liquid storage hair are combined to be a conical fiber brush head. An ultra-long functional nano film prepared by the invention has good repeatability.

Owner:BEIJING SCITECH NANOTECH CO LTD

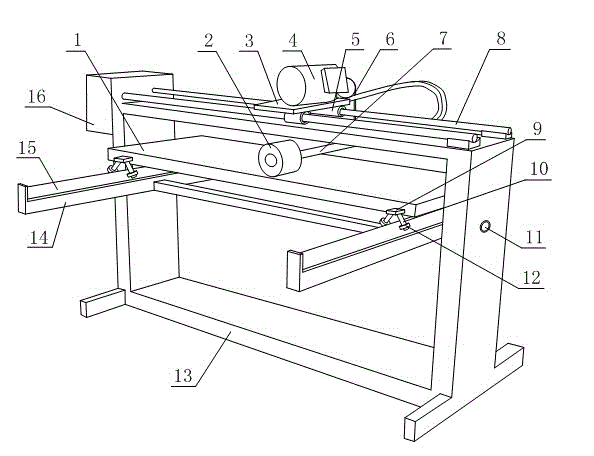

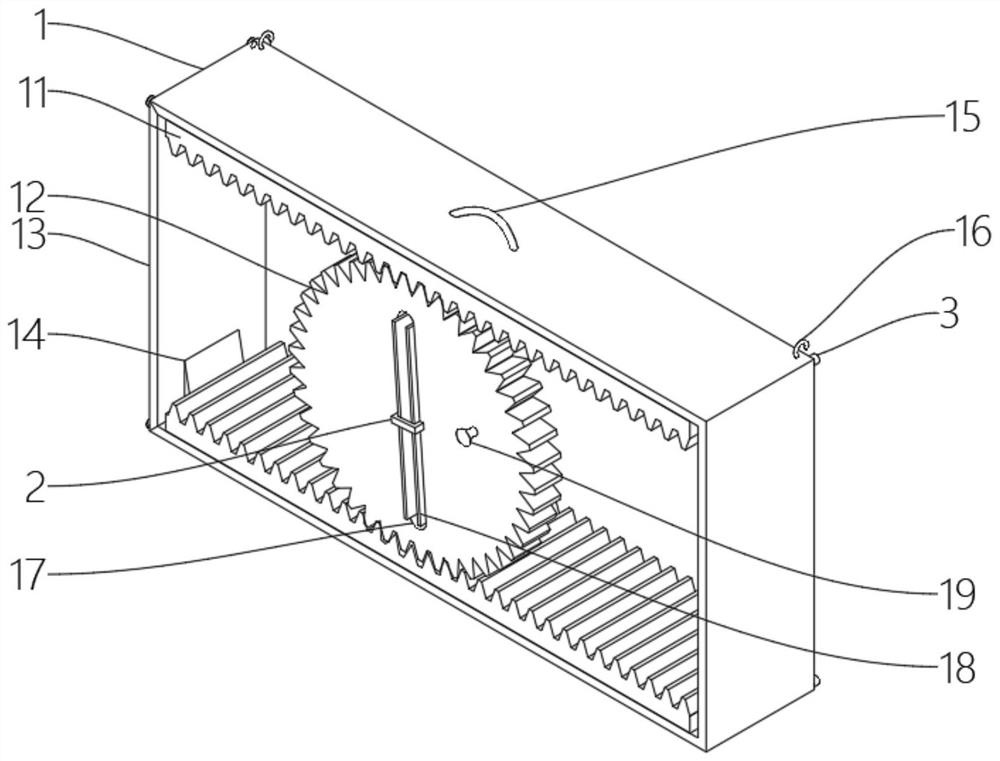

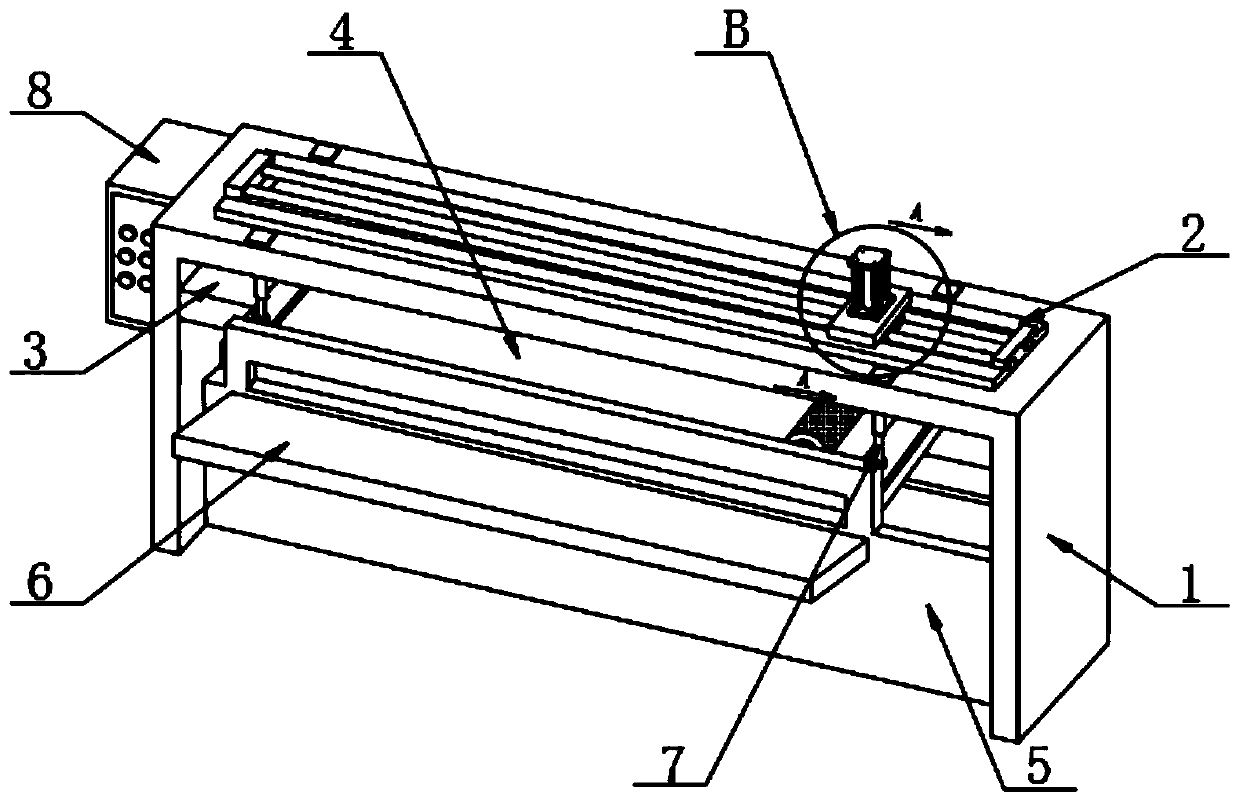

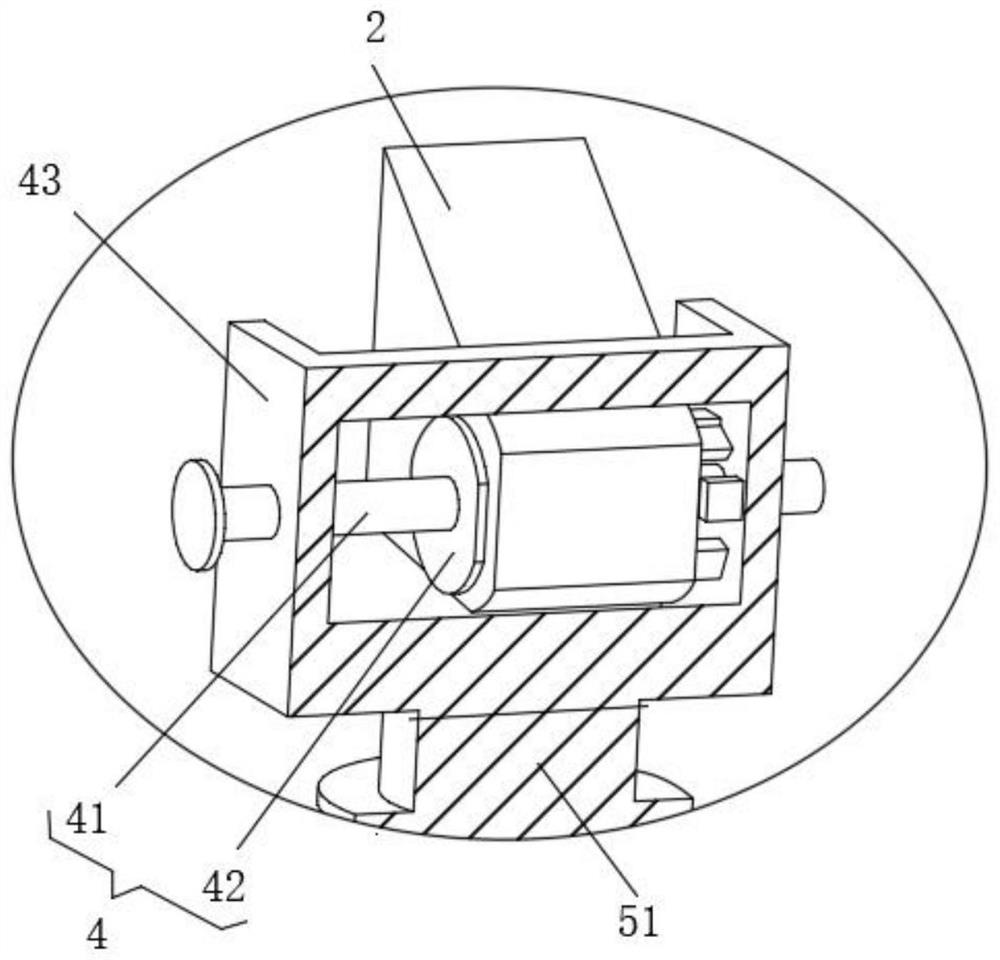

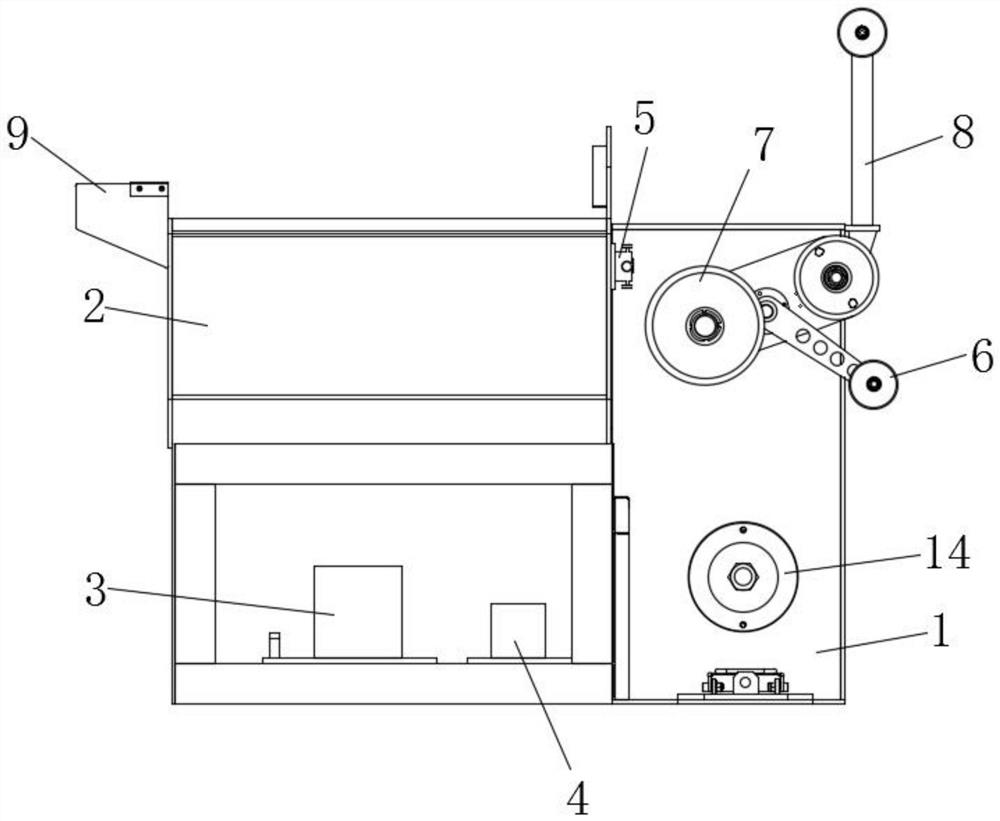

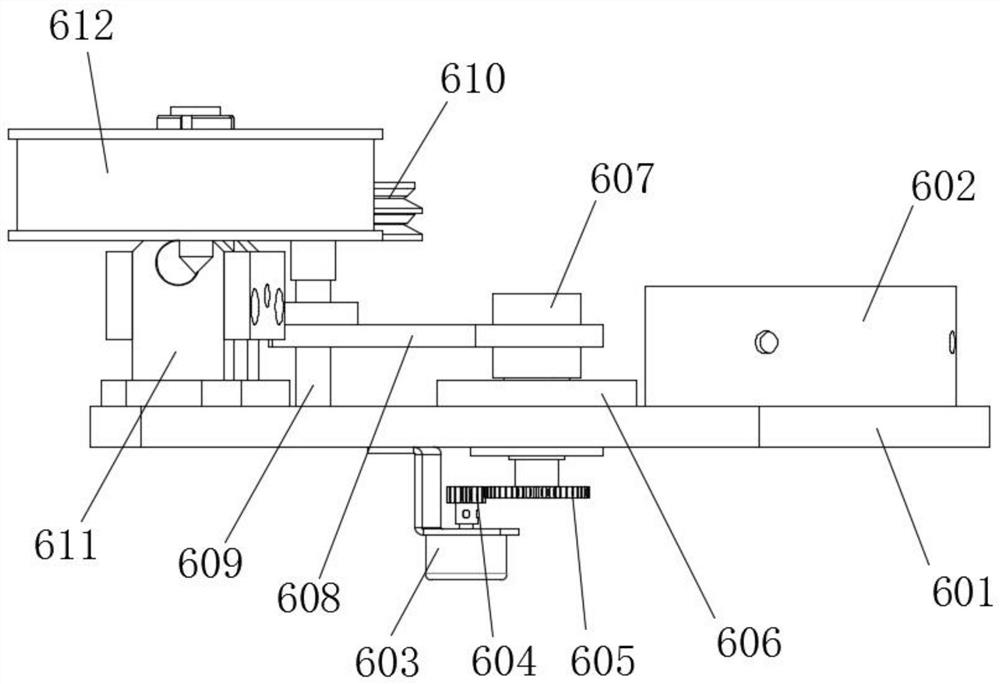

Device capable of improving wiredrawing quality

InactiveCN104608017ADrawing quality is stableSuitable for mass productionPlane surface grinding machinesHigh volume manufacturingEngineering

The invention discloses a device capable of improving wiredrawing quality. A supporting platform is arranged in a cavity of a supporting frame, a limiting frame is arranged below the supporting platform, and positioning pins are arranged in the supporting frame and penetrate through the supporting frame and the limiting frame at the same time. Guide rods are arranged on the supporting frame and fixed to the supporting frame, the guide rods are sleeved with guide sleeves, a supporting plate is arranged on the guide sleeves, a motor is fixed to the supporting plate, a control box is arranged on the outer wall of the supporting frame, the control box is connected with the motor, a wiredrawing brush is arranged in the supporting frame, a central shaft is arranged in the wiredrawing brush, the central shaft penetrates through the center of the wiredrawing brush and is fixed to the wiredrawing brush, the central shaft is sleeved with a belt, and the belt is connected with the central shaft and a belt wheel on the motor. The device is simple in structure, the principle is simple, wiredrawing can be conducted on a stainless steel plate, the wiredrawing process is stable, tracks are unique, the wiredrawing quality of the stainless steel surface is stable, the device is suitable for mass production of an enterprise, and the labor intensity is lowered.

Owner:CHENGDU TAOMASI BATHROOM

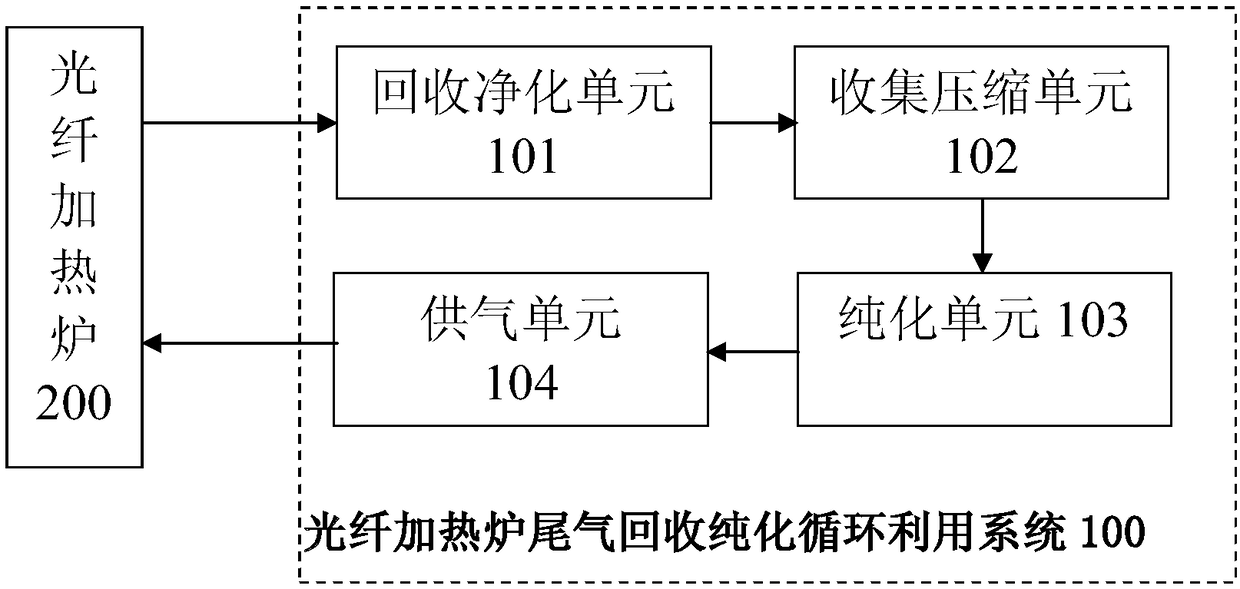

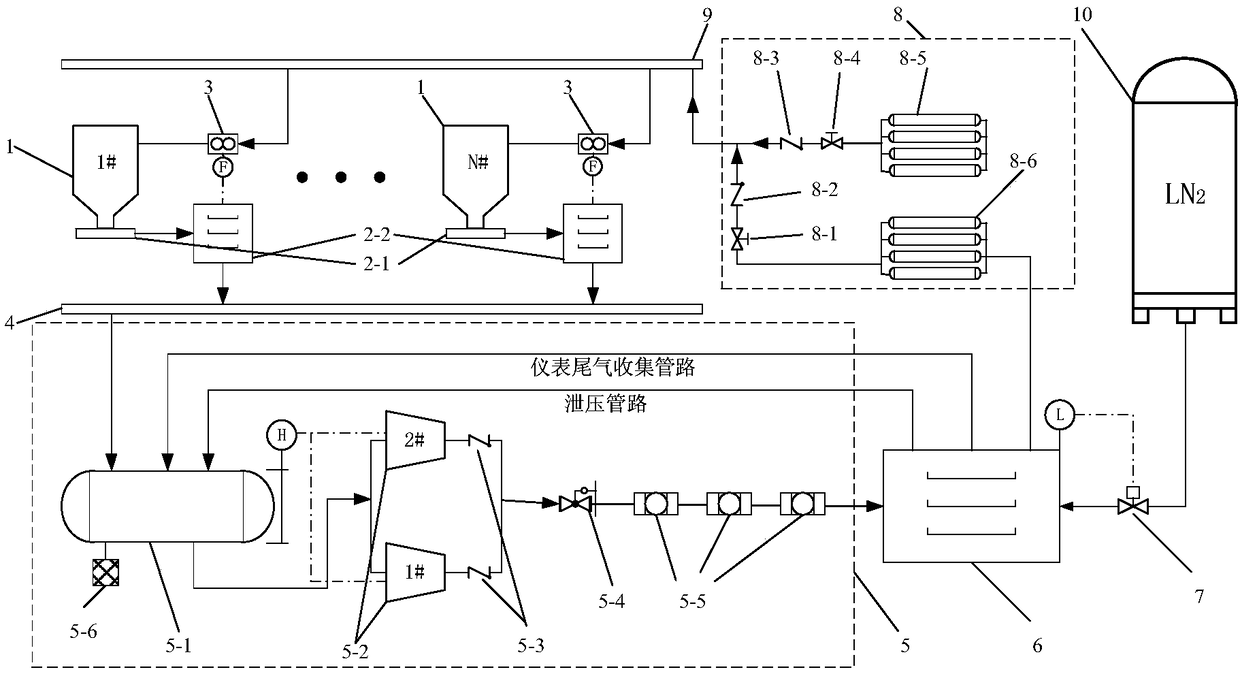

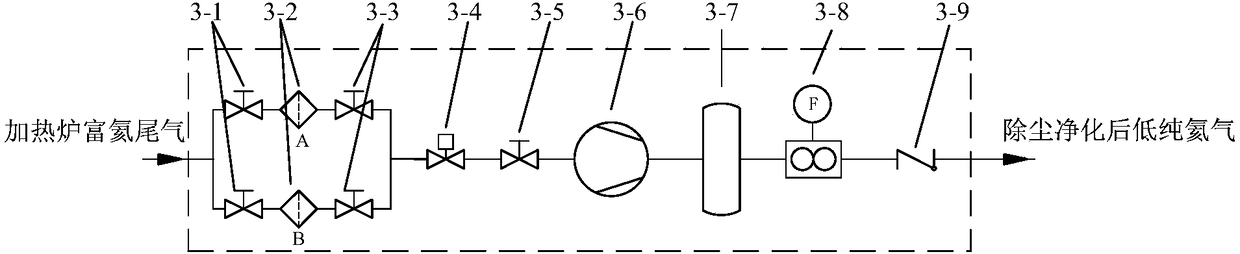

Optical fiber heating furnace exhaust recovery and purification recycling system and method thereof

InactiveCN108569682AImprove work efficiencyAvoid physical damageGlass fibre drawing apparatusNoble gas compoundsProcess engineeringHeating furnace

The invention discloses an optical fiber heating furnace exhaust recovery and purification recycling system, which is characterized by comprising a recovering and purifying unit, a collecting and compressing unit, a purifying unit and a gas supply unit, wherein the recovering and purifying unit is used for recovering and purifying helium exhaust from an optical fiber heating furnace; the collecting and compressing unit is connected with the recovering and purifying unit and comprises a controller and a flexible helium balloon and a compressor connected in sequence along the flow direction of helium gas, and the controller controls the operation of the compressor according to the amount of helium in the flexible helium balloon; the purifying unit is used for purifying helium gas supplied from the collecting and compressing unit; and the gas supply unit supplies helium gas to the optical fiber heating furnace and stores helium gas from the purifying unit. The invention also discloses a recycling method of the system. The optical fiber heating furnace exhaust recovery and purification recycling system has the technical features of ensuring high purity and high recovery rate of the helium gas, and being able to operate reliably and fully automatically in an unattended manner for a long time.

Owner:VACREE TECH

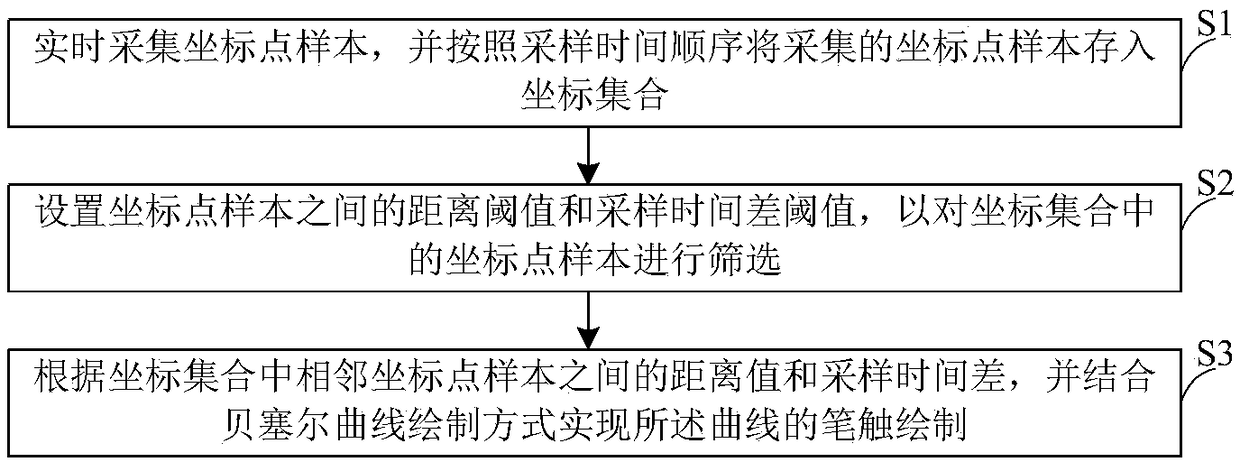

A drawing method for simulating brush strokes

PendingCN109445887AOptimization of drawing fluencyReduce redundant calculationsExecution for user interfacesBrush strokeGraphics

The invention discloses a drawing method for simulating brush strokes, belonging to the technical field of computer graphics processing. The method comprises the following steps of collecting the coordinate point samples in real time, and storing the collected coordinate point samples into a coordinate set according to the sampling time sequence; setting a distance threshold and a sampling time difference threshold between the coordinate point samples to filter the coordinate point samples in the coordinate set; according to the distance value and sampling time difference between adjacent coordinate point samples in the coordinate set, and by combining with the Bezier curve drawing mode, realizing the stroke drawing of the curve. By screening the collected coordinate point samples, the method of the invention realizes the optimization of the drawing fluency, and ensures the stable drawing under the low delay.

Owner:安徽慧视金瞳科技有限公司

Device for preparing glass tube and preparation method for device

ActiveCN108975659AFlexible replacementEasy to replaceGlass pressing apparatusHigh dimensionalHeating furnace

The invention relates to a device for preparing a glass tube and a preparation method for the device. The device comprises a molding mechanism, an extruding mechanism and a drawing mechanism, whereinthe molding mechanism comprises an upper mold, a lower mold and a heating furnace; the upper mold is adapted to a columnar cavity of the lower mold, and a molding part is arranged in the lower mold and is used for molding the glass tube. The device further comprises a feedback link mechanism which is used for controlling the extruding mechanism and the drawing mechanism so as to achieve the feedback linkage of extruding rate and drawing rate. The preparation method comprises the steps of firstly, subjecting materials to heat treatment so as to soften the materials, then, carrying out extruding, carrying out annealing, and then, carrying out drawing, thereby obtaining the glass tube. The glass tube prepared by the method has the advantages of high dimensional precision, high roundness and good linearity and has the outer diameter variation of + / -0.05mm and the inner diameter variation of + / -0.05mm; through replacing a mold, glass tubes, glass sticks and the like of different sizes and shapes can be extruded and drawn.

Owner:CHINA BUILDING MATERIALS ACAD

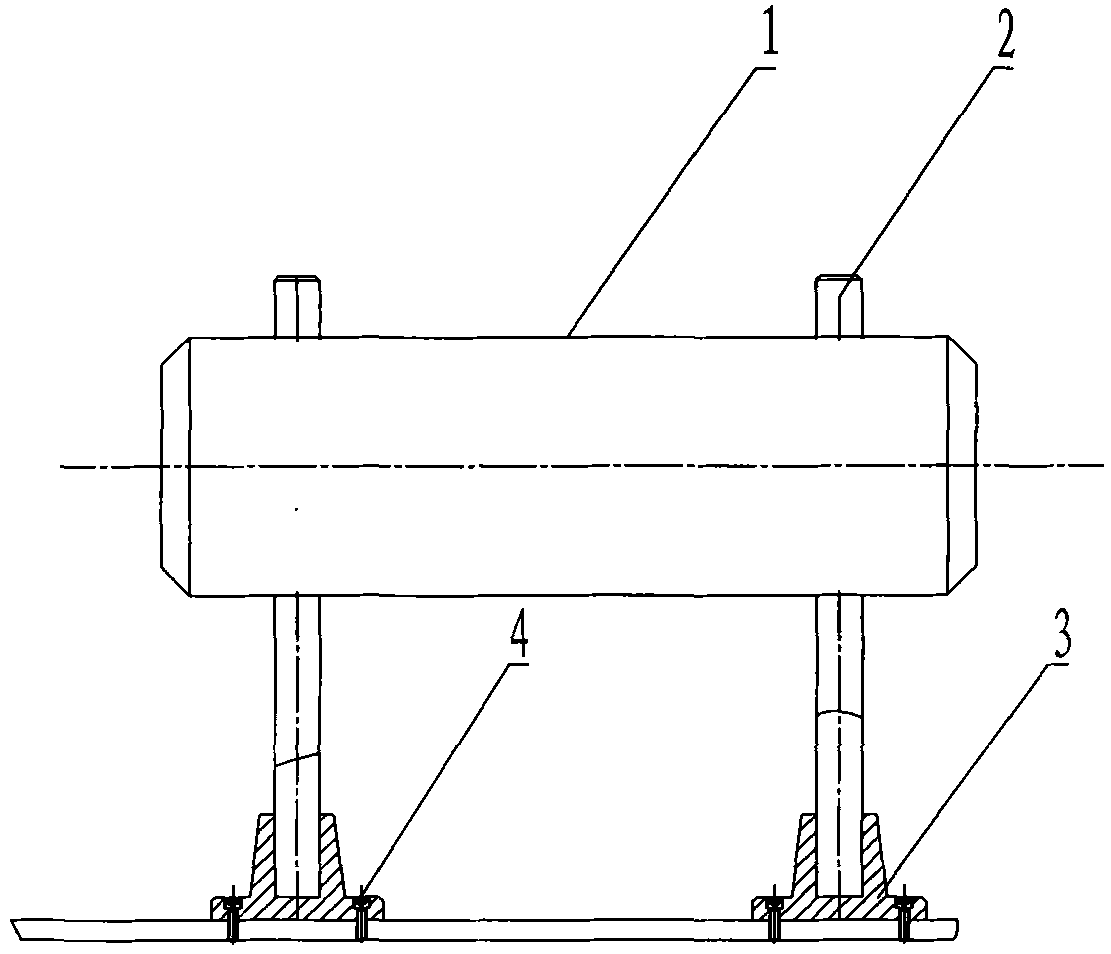

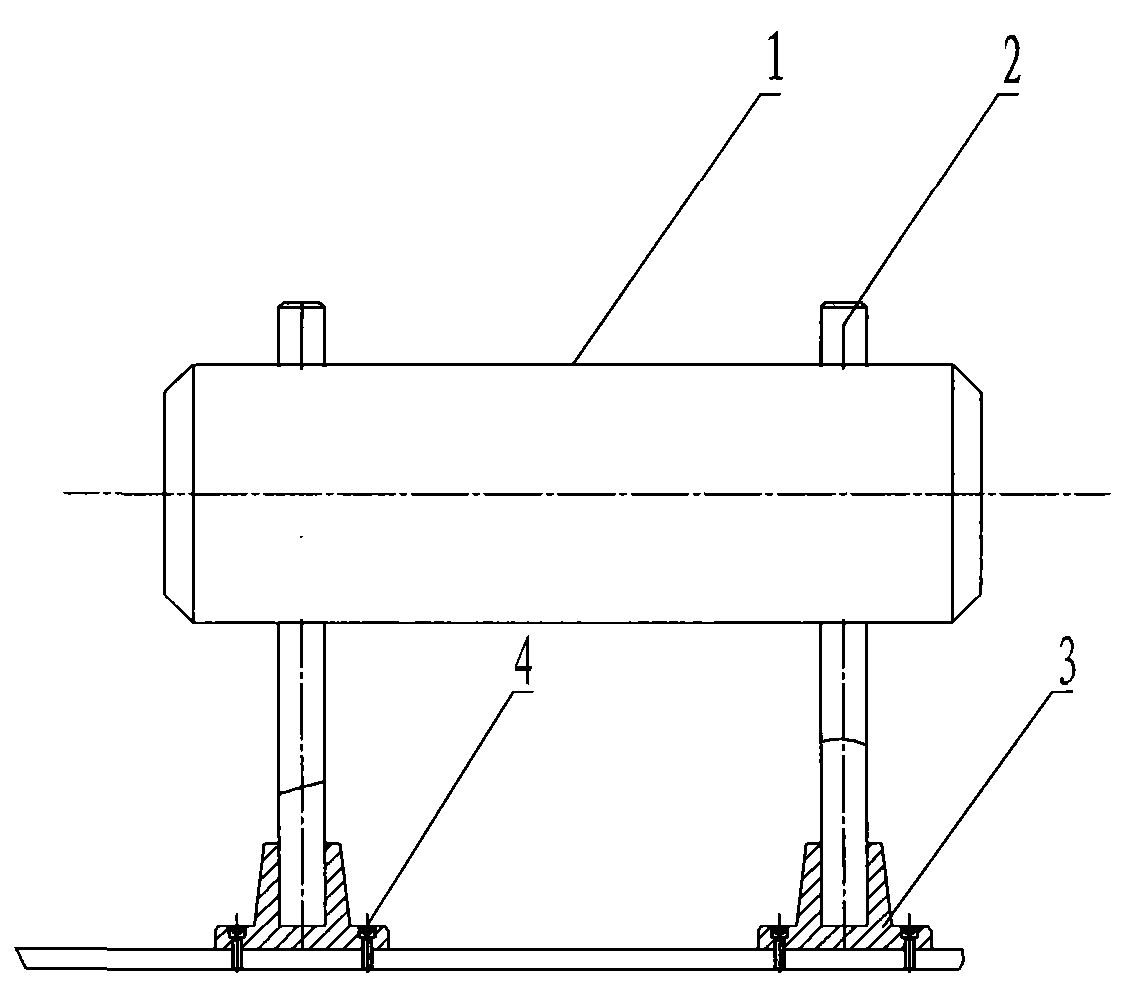

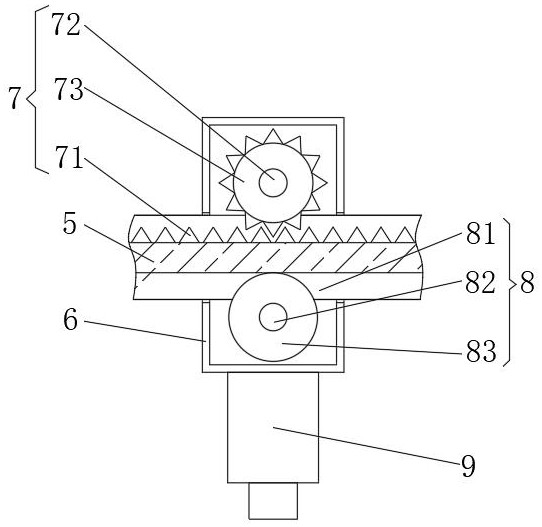

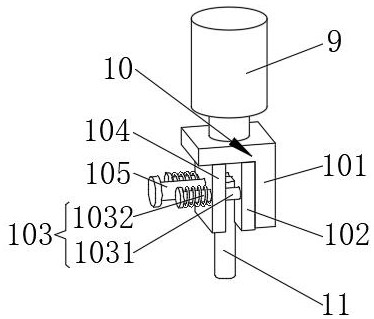

Balance weight mechanism of wire drawing machine

The invention relates to a balance weight mechanism of a wire drawing machine, particularly used for stabilizing a wire drawing on the wire drawing machine. The balance weight mechanism comprises a balance weight block, a supporting rod and a supporting base, wherein the supporting base is fixed at one side of a cover of a turning box body by using hexagon socket cap screws, the supporting rod is inserted into the supporting base, the balance weight block is sleeved on the supporting rod, and the balance weight block is fixed on the supporting rod by using the hexagon screws. The invention has simple, reasonable and economical structure and convenient disassembling and assembling, and can effectively stabilize a turning cover and the wire drawing.

Owner:WUXI PINGSHENG SCI & TECH

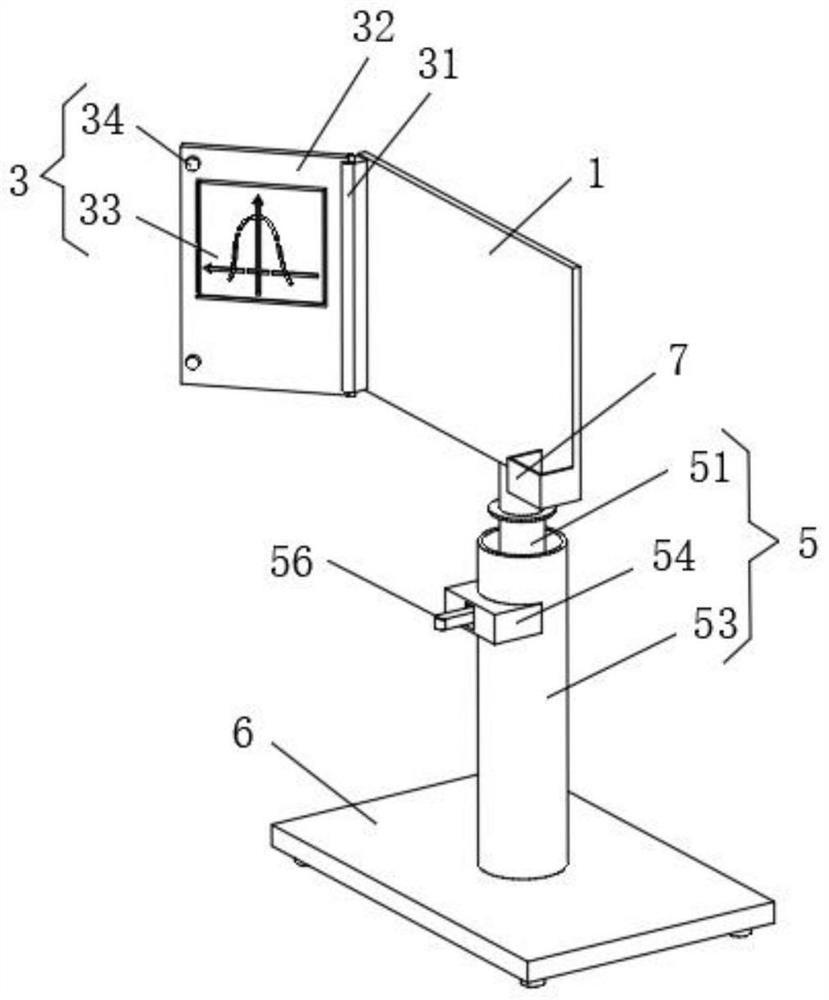

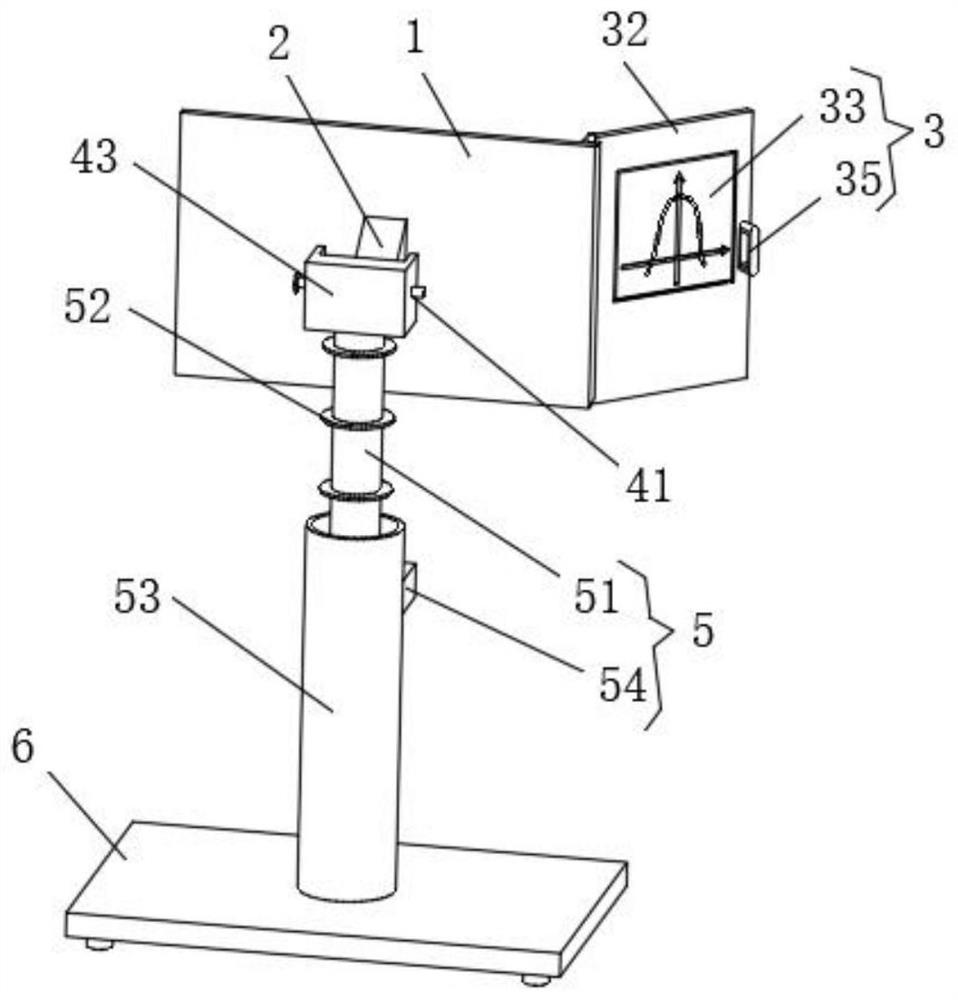

Cycloid teaching aid for university mathematics

PendingCN114038277APrevent slippingInsulation against condensation or water vaporNon-circular curve drawing instrumentsEducational modelsStructural engineeringCycloid

The invention discloses a cycloid teaching aid for university mathematics. The device comprises a frame body. A movable plate body is arranged on one side face of the frame body. Parallel racks are arranged on the two opposite inner side faces of the frame body. A limiting baffle is arranged at the position, close to the movable plate body, in the frame body. A disc rolling body is arranged in the frame body, and the disc rolling body is meshed with the racks. A through groove is formed in the disc rolling body, and the central axis face of the through groove passes through the central axis of the disc rolling body. Sliding rails are fixedly connected to the two sides of the through groove, and a sliding fit frame is arranged on the sliding rails. The sliding rails with scale marks are arranged on the two sides of the through groove, sliding relative to the sliding rails can be achieved through the sliding fit frame, then the position of chalk on the disc is controlled, and cycloid drawing demonstration at all positions is achieved. The sliding fit frame and the sliding rails can be fixed through fixing bolts on the two sides of the sliding fit frame, and a buffering piece arranged in an installation sleeve arranged on the bottom face of the sliding fit frame is used for clamping chalk so as to guarantee that cycloid drawing lines are clear and visible.

Owner:ZHEJIANG INT MARITIME COLLEGE

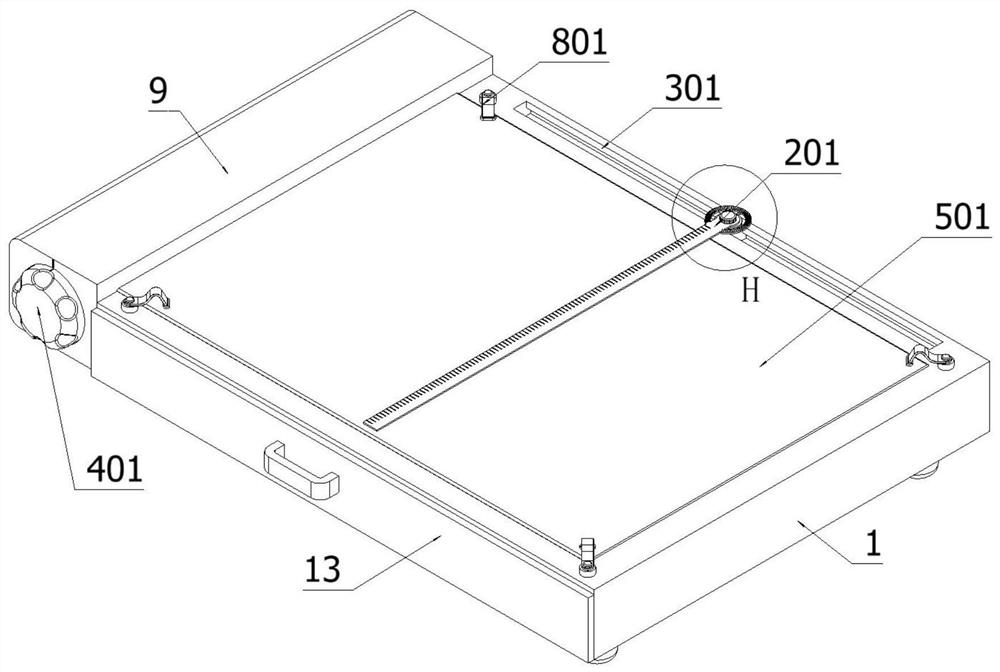

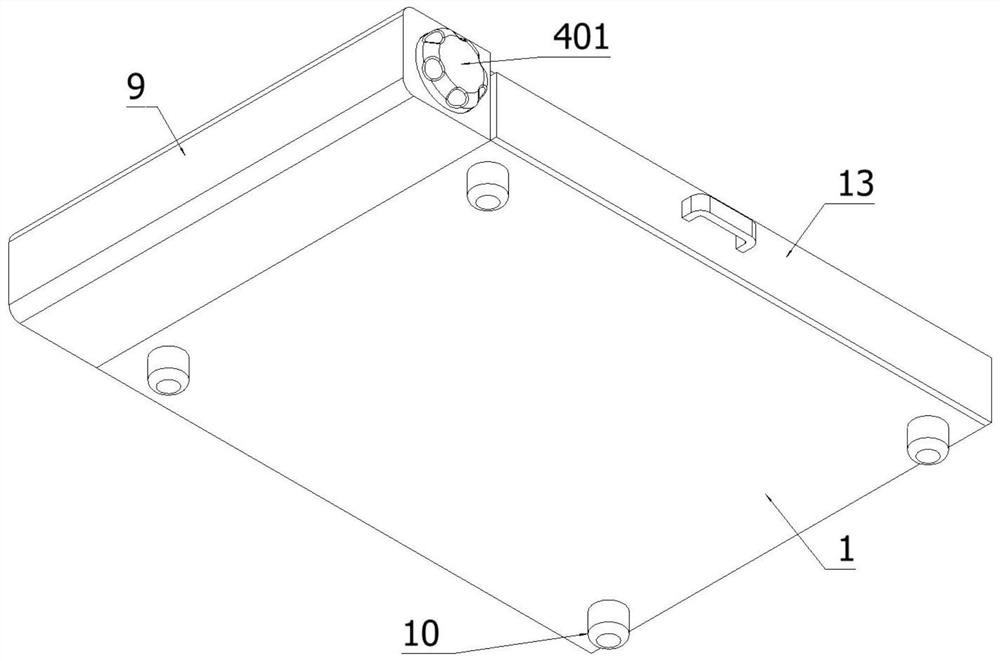

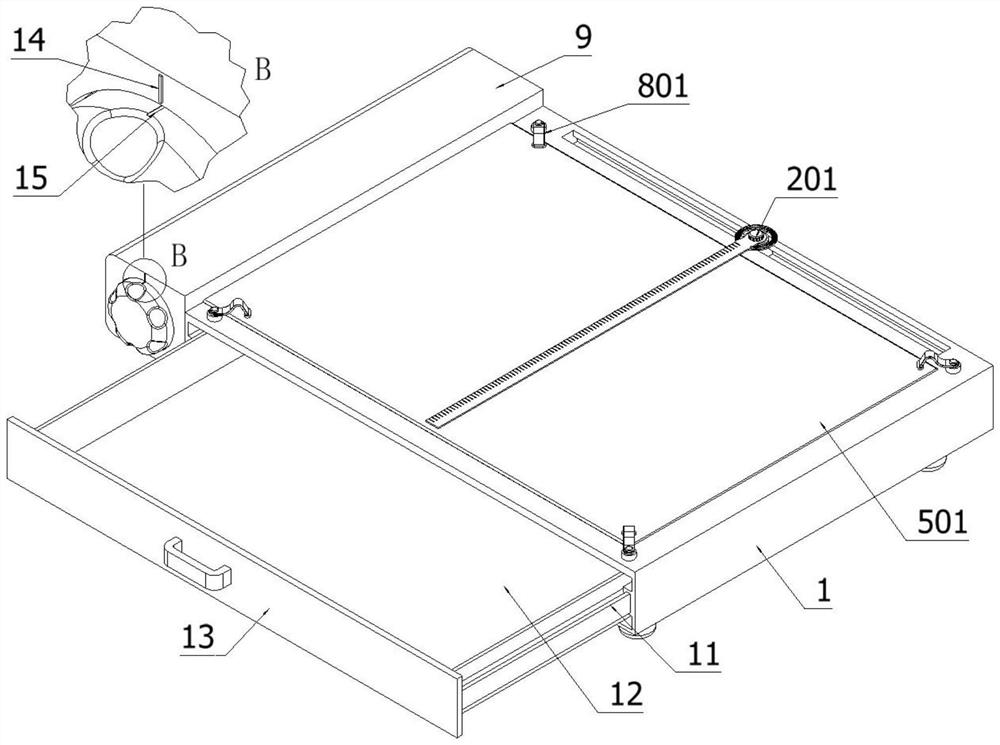

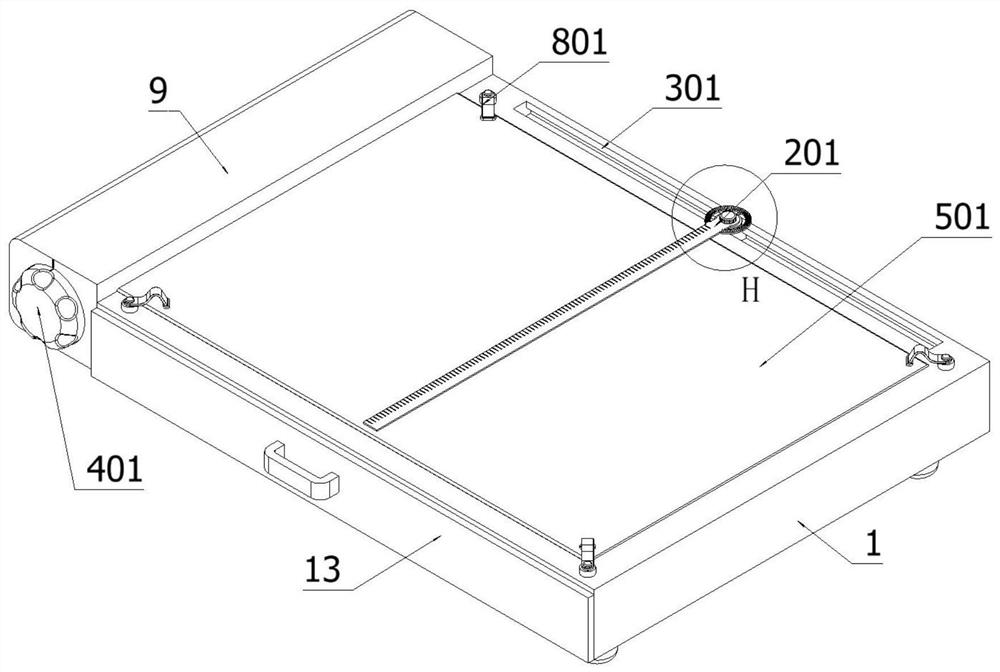

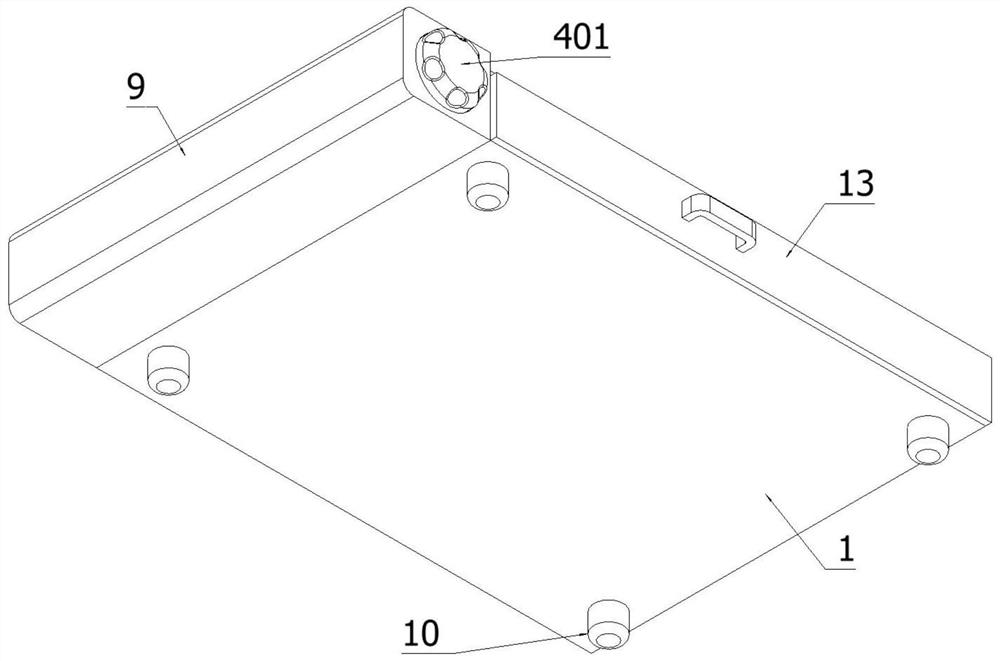

Special drawing auxiliary tool applied to architectural design

ActiveCN113147239AGuaranteed tightnessEasy to insertWriting aidsDrawing boardsRotational axisEngineering

The invention provides a special drawing auxiliary tool applied to architectural design. The special drawing auxiliary tool comprises a mounting shell, wherein anti-skid mounting feet are fixedly connected to four corners of the bottom of the mounting shell; a sliding device is fixedly connected to the top of the mounting shell, and an auxiliary drawing device is fixedly connected to the sliding device; reel mounting boxes are fixedly connected to the side face of the mounting shell, and a rotating shaft in each reel mounting box is connected with a reel device; two groups of rotary limiting devices are fixedly connected to each reel device; and a drawing backup device is fixedly connected to the top of the mounting shell, the drawing backup device is arranged, the mode that drawing printing paper is attached to a sealing film is adopted, the sealing film can effectively guarantee the sealing effect of a backup drawing, the drawing which is being drawn is copied through the drawing printing paper, and the condition that the first drawing is damaged and lost, and water is splashed to cause reworking and reduction of the working efficiency of building construction if backup is not performed in time is avoided.

Owner:杭州朴筑建筑设计有限公司

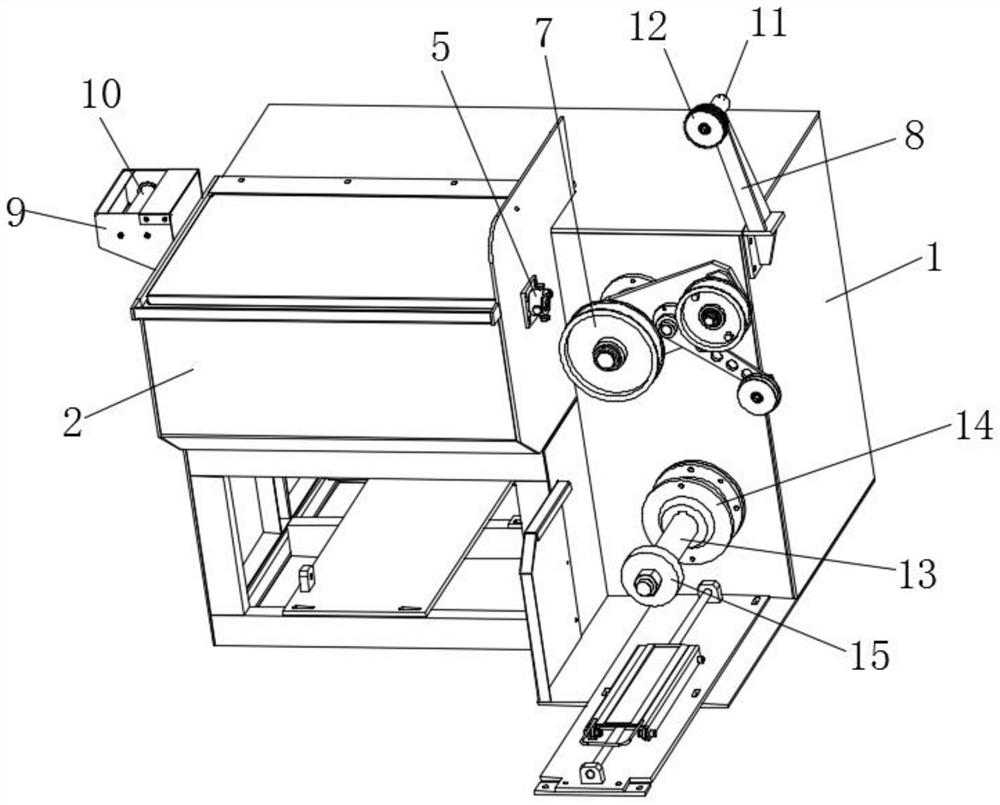

Surface treatment device for aluminum magnesium alloy die castings

InactiveCN110434722AStable drawingGuaranteed drawing effectGrinding drivesGrinding machinesDie castingMaterials science

The invention discloses a surface treatment device for aluminum magnesium alloy die castings, and in particular relates to the technical field of surface treatment. The surface treatment device comprises a rack, a through groove is formed in the top end of the rack, and a base is welded on the edge, close to the through groove, of the rack. A cross beam is arranged at the position, close to the top end, of the inner side of the rack, and the cross beam is welded with rack. A working platform is arranged on the upper surface of the cross beam, and a wire drawing mechanism is arranged on the upper surface of the base. The wire drawing mechanism comprises a group of sliding rods transversely inserted into the base, and transverse transplanting cylinders are fixedly arranged on the outer surfaces of the sliding rods in a sleeving mode. Pressing plates are erected at the two ends in the transverse direction of the top end of the working platform, and pressing cylinders are fixedly arrangedat the two ends in the radial direction of the upper surfaces of the pressing plates through bolts. Compared with the prior art, the surface treatment device is not limited by dies and ensures that the wire drawing area is not limited, so that the wire drawing process of the aluminum magnesium alloy die castings is stable, and the wire drawing effect is ensured.

Owner:巢湖宜安云海科技有限公司

A brush printing film-making device and a nano-film printing method based on the device

ActiveCN109693329BImprove adaptabilityAvoid distortionNanostructure manufactureFlat articlesFiberEngineering

Owner:BEIJING SCITECH NANOTECH CO LTD

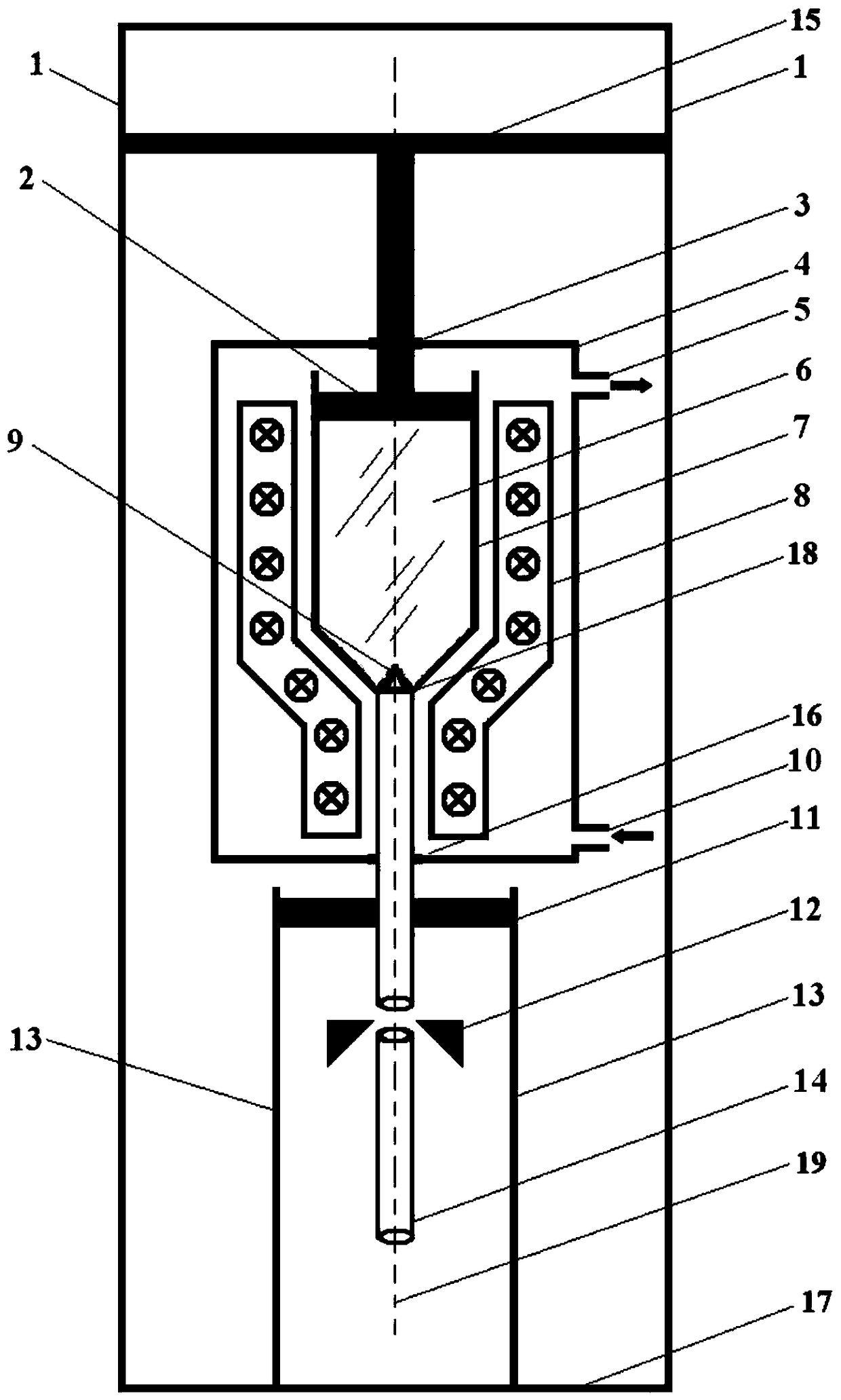

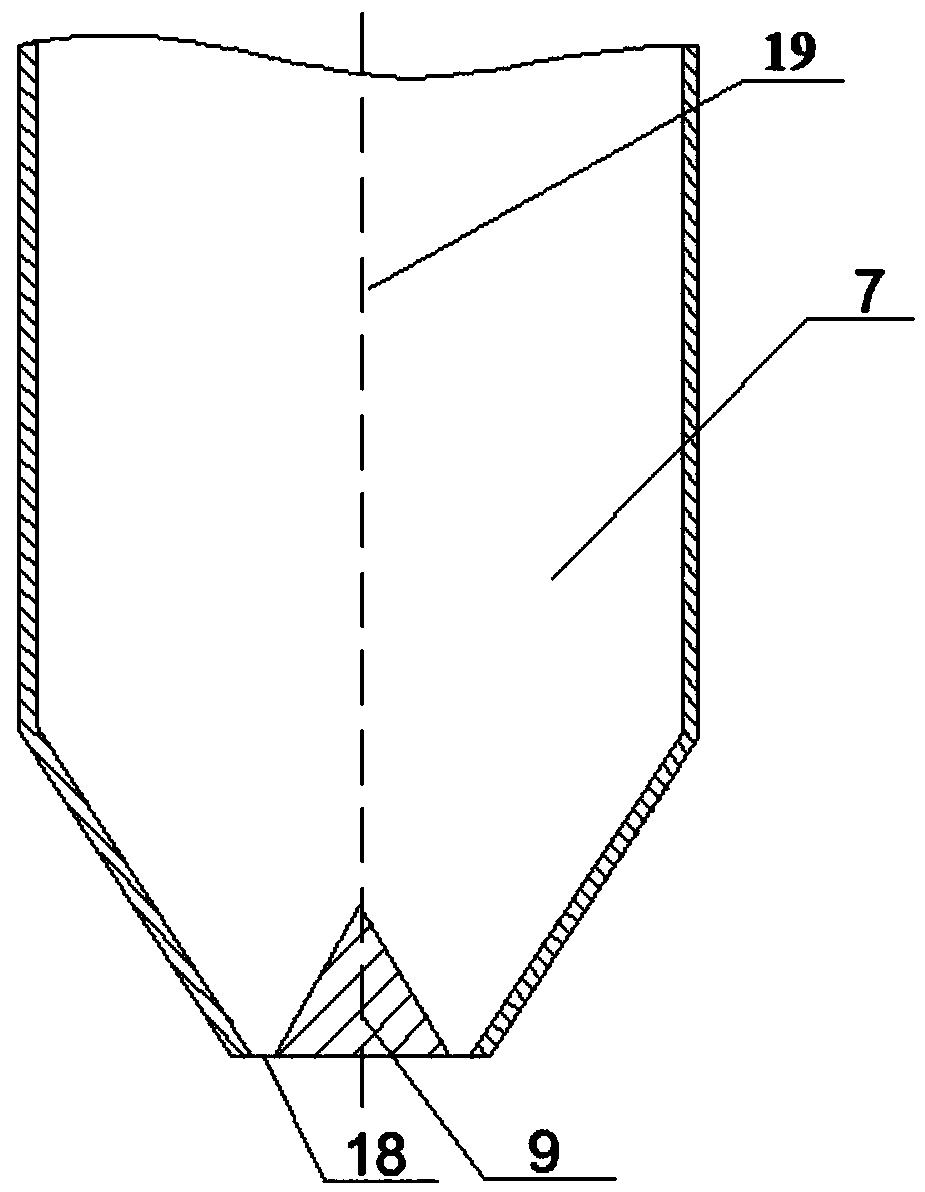

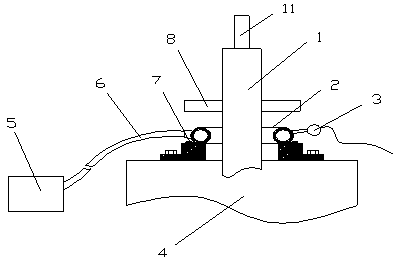

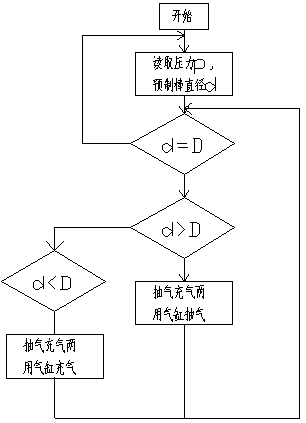

A sealing device and control method for the mouth of a wire drawing furnace

ActiveCN106219963BGuaranteed tightnessStable drawingGlass making apparatusAutomatic controlMeasuring instrument

An apparatus for sealing a furnace mouth of a drawing furnace and a sealing control method. The apparatus comprises: an extendable and retractable sealing ring which is provided coaxially with the furnace mouth of the drawing furnace; an air extracting / inflating device which extracts air from or inflates air to the extendable and retractable sealing ring to change the pressure in the extendable and retractable sealing ring and correspondingly change the inner diameter of the extendable and retractable sealing ring; a laser diameter measuring instrument for measuring the actual diameter of an optical fiber preform; a pressure sensor for measuring the pressure in the extendable and retractable sealing ring; and a controller which analyzes, according to the measured pressure in the extendable and retractable sealing ring and the measured actual diameter of the optical fiber preform, diameter data of the optical fiber preform to control the air extracting / inflating device to extract air from or inflate air to the extendable and retractable sealing ring, so that the inner ring surface of the extendable and retractable sealing ring always abuts against the optical fiber preform. The control method can seal a gap between the furnace mouth of the drawing furnace and the optical fiber preform.

Owner:ZHONGTIAN TECH FIBER OPTICS +1

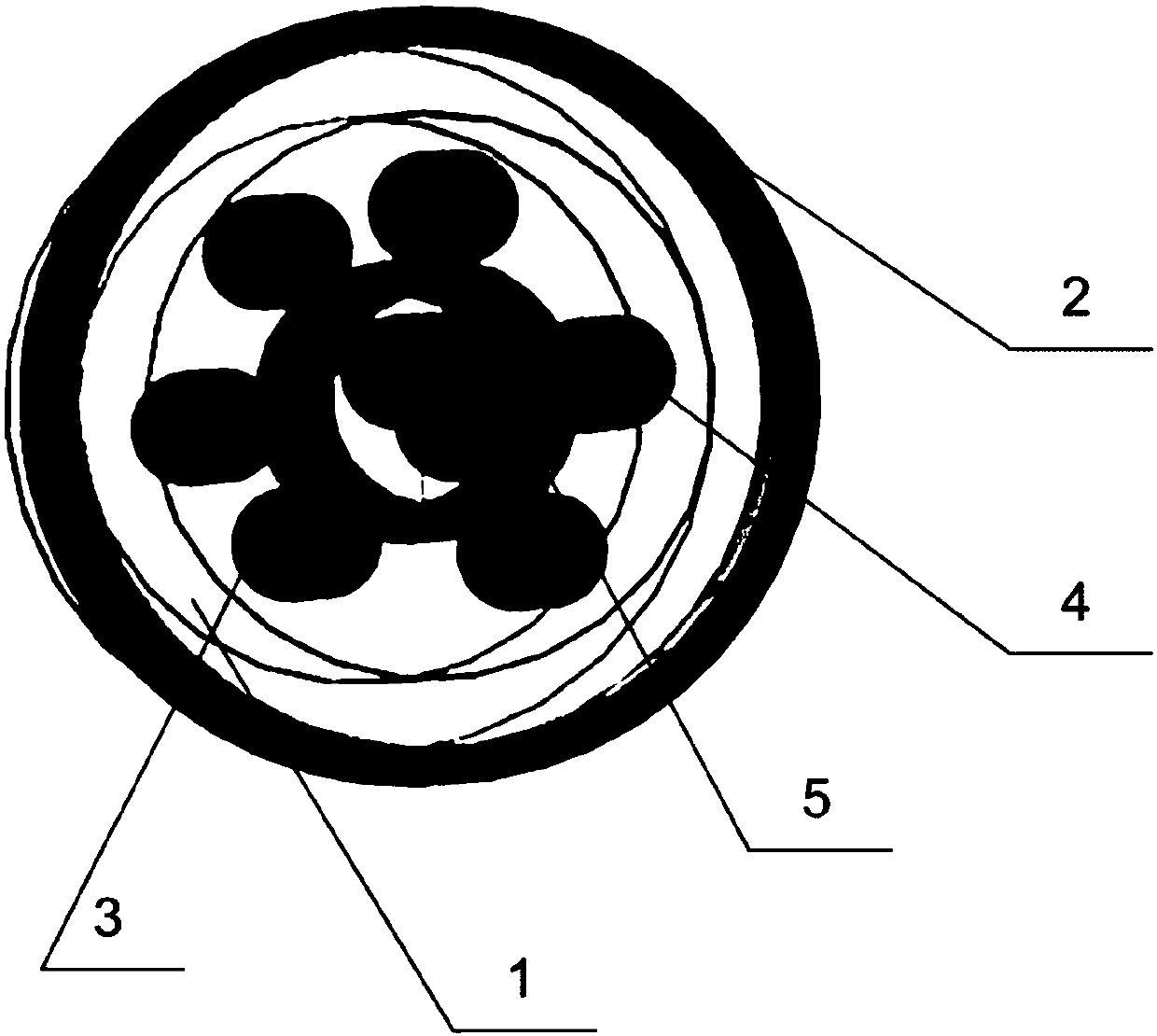

A kind of cable drawing structure and cable drawing method

ActiveCN111760919BGood drawing tension maintenance effectGuaranteed to workReduction of cables/conductors sizeStructural engineeringElectrical and Electronics engineering

Owner:青海鑫邦线缆有限公司

Ball grinding mill bearing bush lubricating oil and manufacturing method thereof

ActiveCN102559347BImprove the lubrication effectReduce the temperatureBase-materialsPolyesterEngineering

Ball grinding mill bearing bush lubricating oil and a manufacturing method thereof solve the problem that a ball grinding mill bearing bush is poor in lubrication in the severe environment. The ball grinding mill bearing bush lubricating oil is formed by using synthetic oil as base oil and refining multiple added efficient composite additives, has the advantages of being abrasion-resisting, high-temperature-resisting, oxidation-resisting, firm in formed film and the like, and can repair wire drawing and reduce abrasion and bearing bush temperature at fastest speed. The work efficiency and the product quality are improved obviously, the repair and maintenance costs are reduced, the service life of a device is prolonged, and energy consumption is reduced greatly. The ball grinding mill bearing bush lubricating oil is composed of, by mass, mineral lubricating oil 49%-69%, polyester synthetic oil 20%-40%, thickening agent 0.05%-0.15%, organic molybdenum composite additive 2.5%-4.5%, T306 additive 1%-3%, T202 antioxygen 0.4%-0.6%, T551 metal deactivator 0.7%-0.9% and T704 antirust additive 0.6%-0.8%, wherein the summation of the components is a hundred percent.

Owner:洛阳正本润滑材料有限公司

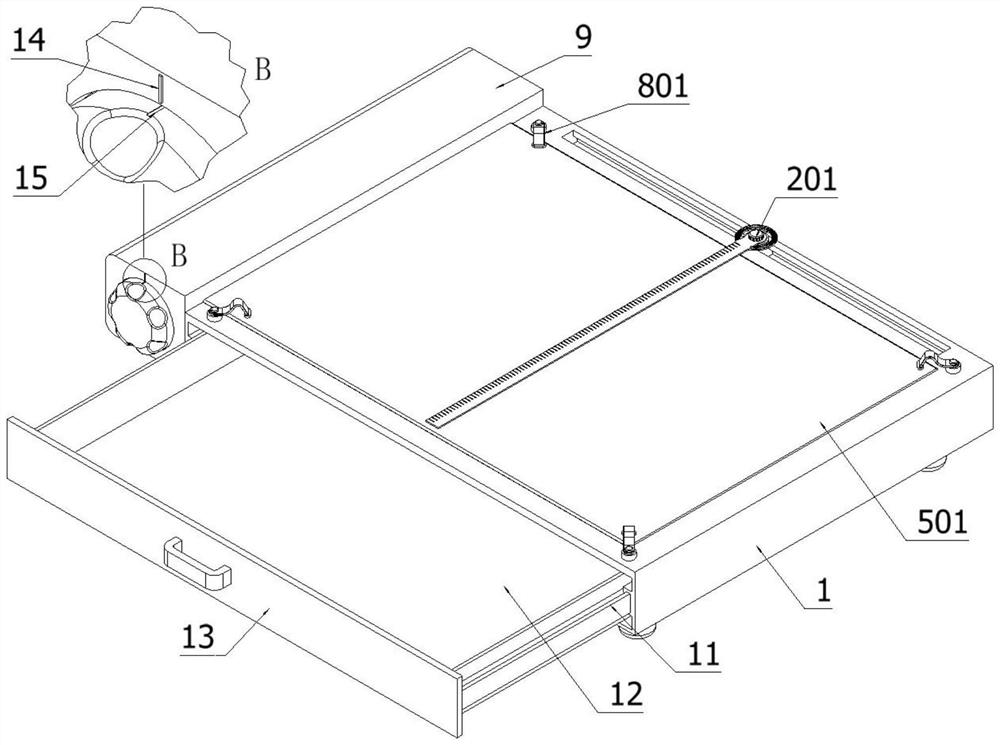

Line drawing and positioning integrated device for garment decoration splicing process

The invention discloses a line drawing and positioning integrated device for a garment decoration splicing process. The device comprises a workbench, a first limiting mechanism is arranged on the right side of the top of the workbench, and a front-back moving mechanism is arranged on the left side of the top of the workbench. Firstly, cloth is flatly laid on the top of a workbench, and the cloth is fixed through two second clamps; the situation that cloth deviates in scribing process of chalk body is avoided, and the purpose of stable scribing can be achieved. The first clamp and the chalk body can move freely at the top of the workbench through the front-back moving mechanism and the left-right moving mechanism, drawing of straight lines, curves and oblique lines can be achieved, the purpose of high automation degree can be achieved, and after scribing is completed, cloth is taken down from the top of the workbench and inserted between a positioning base and a transverse plate, the spliced position is positioned through the positioning mechanism, repositioning in the sewing process is avoided, positioning is also achieved in a mechanical mode, and the purpose of high comfort levelcan be achieved.

Owner:孙国林

Mathematics teaching board capable of rapidly drawing function curve

InactiveCN114851747AQuick drawStable drawingWriting boardsNon-circular curve drawing instrumentsDisplay boardStructural engineering

The invention discloses a mathematics teaching board capable of rapidly drawing a function curve. The mathematics teaching board comprises a display board, a function drawing unit and an angle adjusting unit, a connecting angle block is mounted at the rear end of the middle of the display board; the function drawing unit comprises a movable seat, a movable plate, a function groove plate, a sucker and a movable plate handle, the movable seat is mounted on the front side of the left end of the display plate, the right end of the movable plate is rotatably connected with the movable seat through a movable vertical column, the function groove plate is clamped in the middle of the movable plate, and the sucker is mounted on the left side of the front end of the movable plate. The movable plate handle is mounted at the left rear end of the movable plate; according to the mathematics teaching board capable of rapidly drawing the function curve, function images can be drawn on the display board by replacing different types of function drawing boards, angle and height adjustment is more stable, and the mathematics teaching board can better meet teaching requirements in use.

Owner:枣庄科技职业学院

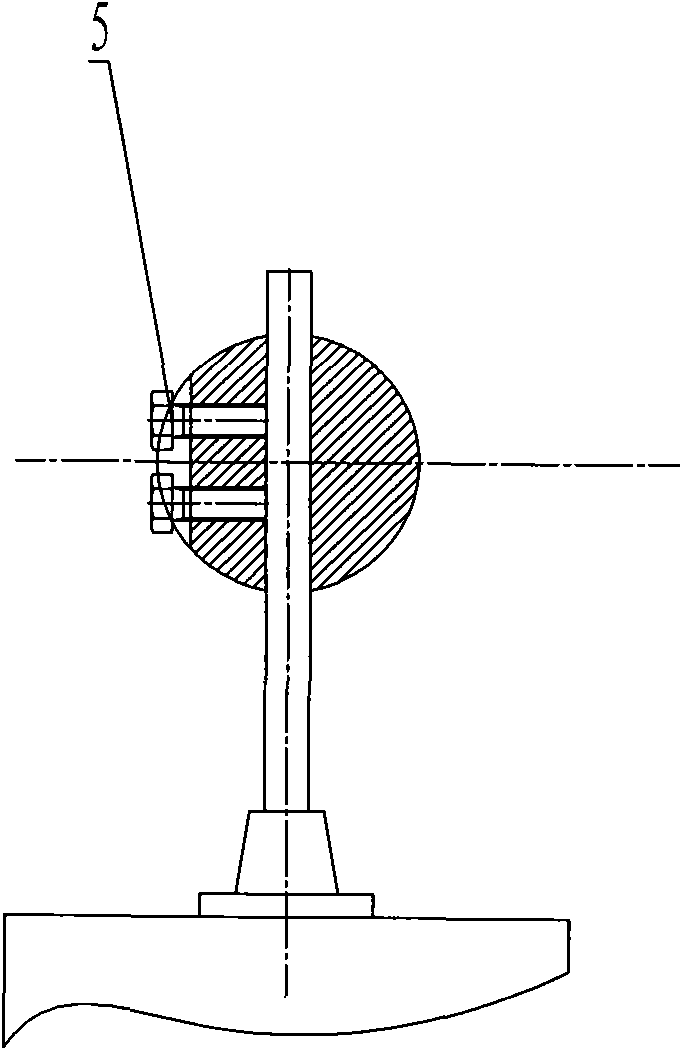

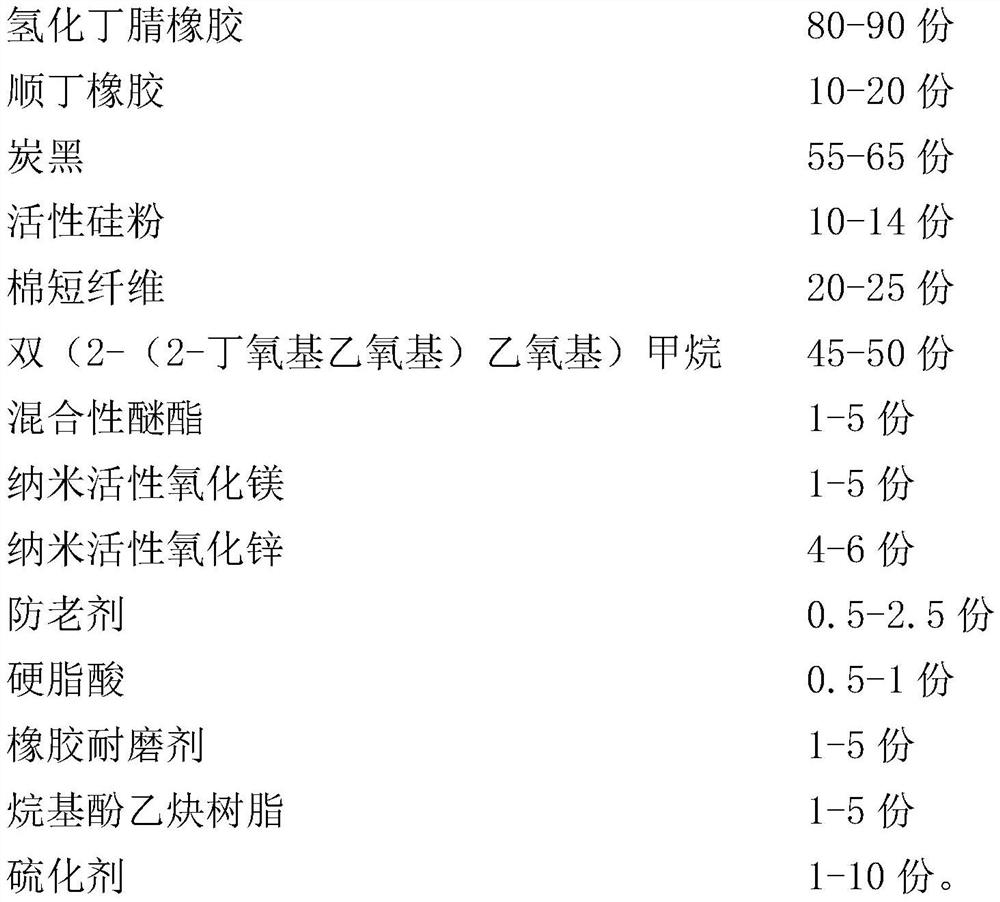

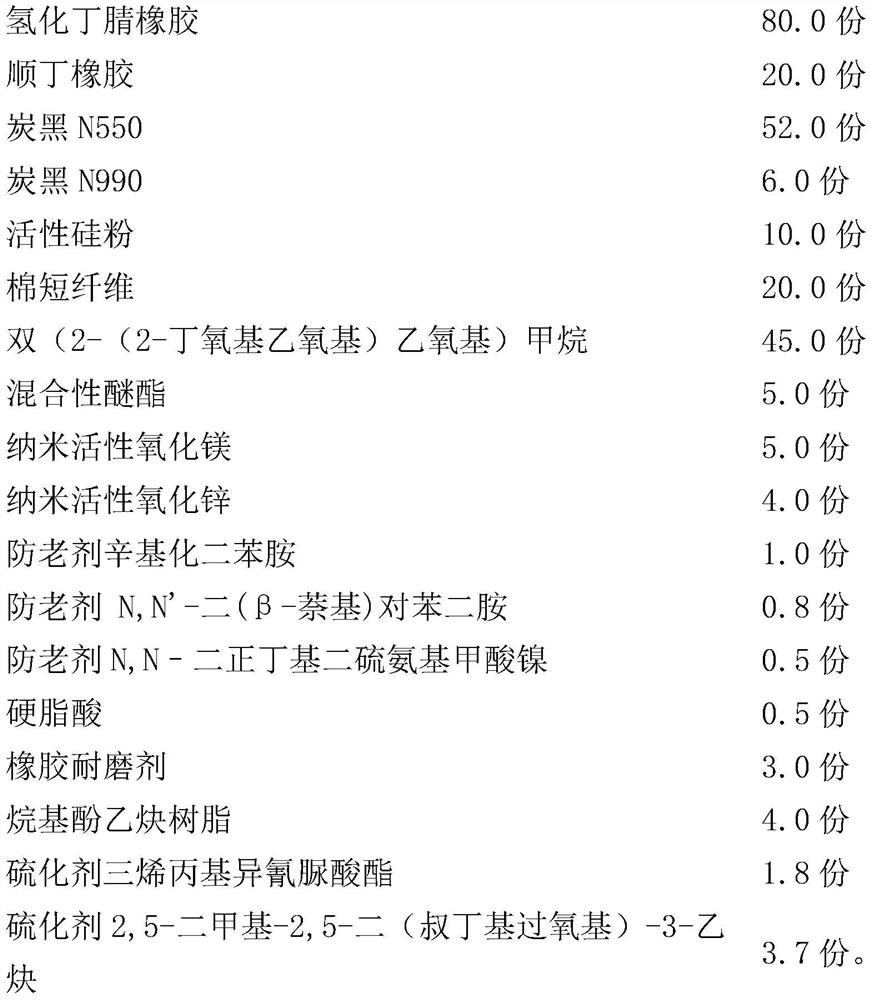

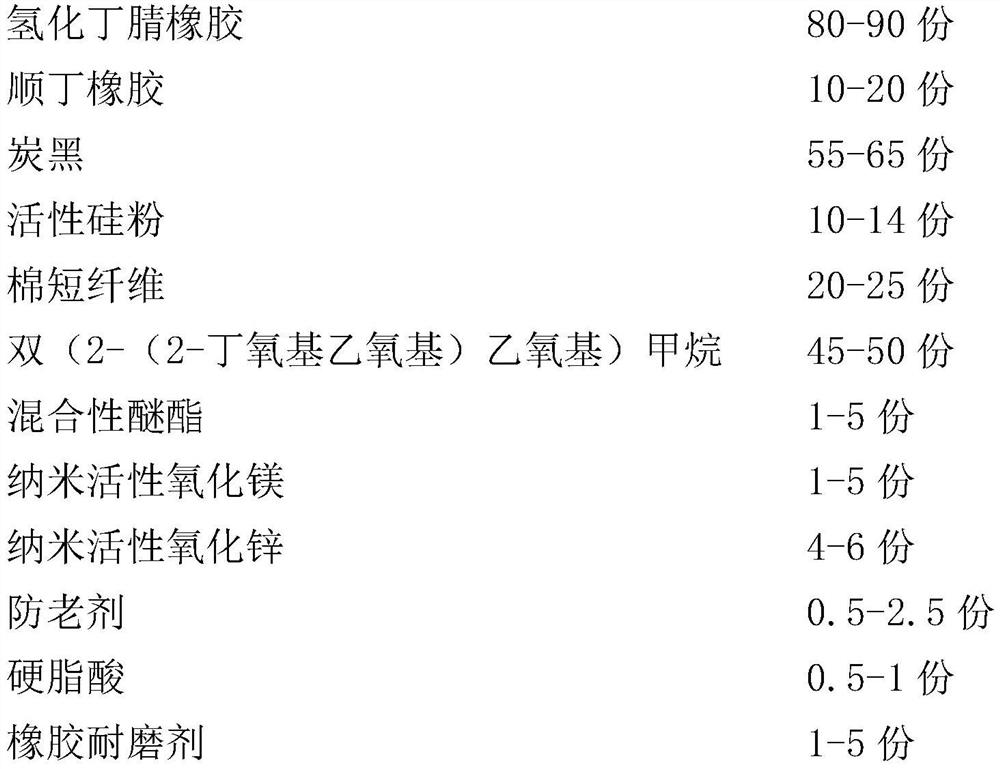

Hydrogenated nitrile rubber material for manipulator clamping jaw of wire drawing machine, and preparation method thereof

The invention discloses a hydrogenated butadiene-acrylonitrile rubber material for a manipulator clamping jaw of a wire drawing machine, and a preparation method thereof. The hydrogenated butadiene-acrylonitrile rubber material comprises hydrogenated butadiene-acrylonitrile rubber, butadiene rubber, carbon black, active silicon powder, short cotton fiber, bis(2-(2-butoxyethoxy)ethoxy)methane, mixed ether ester, nano active magnesium oxide, nano active zinc oxide,. an anti-aging agent, stearic acid, a rubber wear-resistant agent, alkylphenol acetylene resin, triallyl isocyanurate and 2, 5-dimethyl-2, 5-di(tert-butylperoxy)-3-acetylene. According to the invention, the hydrogenated nitrile rubber material is researched and developed, so that the surface viscosity of the material is reduced, the friction resistance and the surface scratch-proof capability are improved, the influence on the original rebound resilience is small, the process operability is obviously improved, the manufacturing process is simple, reliable and stable, and the material is suitable for a manipulator clamping jaw material for automatically drawing optical fibers. The invention also relates to a preparation method of the hydrogenated nitrile rubber.

Owner:CHINA BUILDING MATERIALS ACAD

Thickness-controllable roller brush for metal wire drawing and use method of thickness-controllable roller brush

ActiveCN113103092ANot easy to soften and deformReduce generationGrinding machine componentsPlane surface grinding machinesBrushMetal dust

The invention discloses a thickness-controllable roller brush for metal wire drawing and a using method of the thickness-controllable roller brush, and belongs to the technical field of metal wire drawing. Before a wire drawing procedure is carried out, a T-shaped roller can be rotated according to the thickness of required ropiness, and clamping and pressing parts of a variable-diameter steel wire and a wire adjusting frame are adjusted, so that the part, with the corresponding thickness, on the variable-diameter steel wire is rotated to the wire adjusting frame, the part is pressed by a main pressing bar and an auxiliary pressing bar to bulge, and then a metal workpiece is drawn to obtain the ropiness of required thickness on the surface of the metal workpiece. According to the thickness-controllable roller brush for metal wire drawing and the using method of the thickness-controllable roller brush, the thickness range of the processable ropiness is within the diameter change range of the variable-diameter steel wire, so that the application range of the thickness-controllable roller brush is greatly widened, and in the wire drawing process, due to the contact extrusion between the wire adjusting frame and the variable-diameter steel wire, water on the wire adjusting frame can overflow to the variable-diameter steel wire, dust generated by wire drawing is absorbed, and the influence of metal dust on workers and air is reduced.

Owner:杭州余海金属拉丝有限公司

A kind of preparation technology of power cable for city building

ActiveCN110379563BPull out stableAvoid damageReduction of cables/conductors sizeInsulating conductors/cablesPower cableElectrical conductor

The invention discloses a preparation process of a power cable for urban buildings. The preparation process specifically includes the steps of carrying out wire drawing, stranding conductors, extruding an insulating layer, extruding an inner sheath, wrapping a shielding layer, braiding an armor layer, extruding an outer sheath, carrying out finished product inspection and obtaining a finished product. The shielding layer is formed by wrapping an aluminum-plastic composite tape on a wrapping machine or a cable forming machine, the outer layer of the inner sheath is provided with the aluminum-plastic shielding and the armor layer to form a combined shielding layer, so that the transmission impedance of the power cable is enabled not to be greater than 1 omega / m when the shielding transfer impedance of the finished power cable is reduced to 100MHz or below, thereby ensuring the finished power cable to have good shielding performance, enabling the power cable not to cause interference to adjacent circuits when being electrified and used, and thus increasing the stability of the finished power cable in use.

Owner:TIANCHANG HUILING ELECTRIC APPLIANCE METER FACTORY

A special drawing aid tool applied to architectural design

ActiveCN113147239BGuaranteed tightnessEasy to insertWriting aidsDrawing boardsRotational axisBuilding design

The invention provides a special drawing auxiliary tool applied to architectural design, comprising an installation shell; anti-skid installation feet are fixedly connected to the four corners of the bottom of the installation shell; a sliding device is fixedly connected to the top of the installation shell, and the sliding device An auxiliary drawing device is fixedly connected to it; a reel installation box is fixedly connected to the side of the installation casing, and a reel device is connected to the rotating shaft inside the reel installation box; two sets of rotation limit devices are fixedly connected to the reel device; The top of the installation shell is fixedly connected with a drawing backup device, and a drawing backup device is installed. The drawing printing paper and the sealing film are attached together. The sealing film can effectively ensure the sealing effect of the backup drawings. To prevent the damage and loss of the first draft and the low water, the failure to make backups in time leads to rework and reduces the efficiency of construction work.

Owner:杭州朴筑建筑设计有限公司

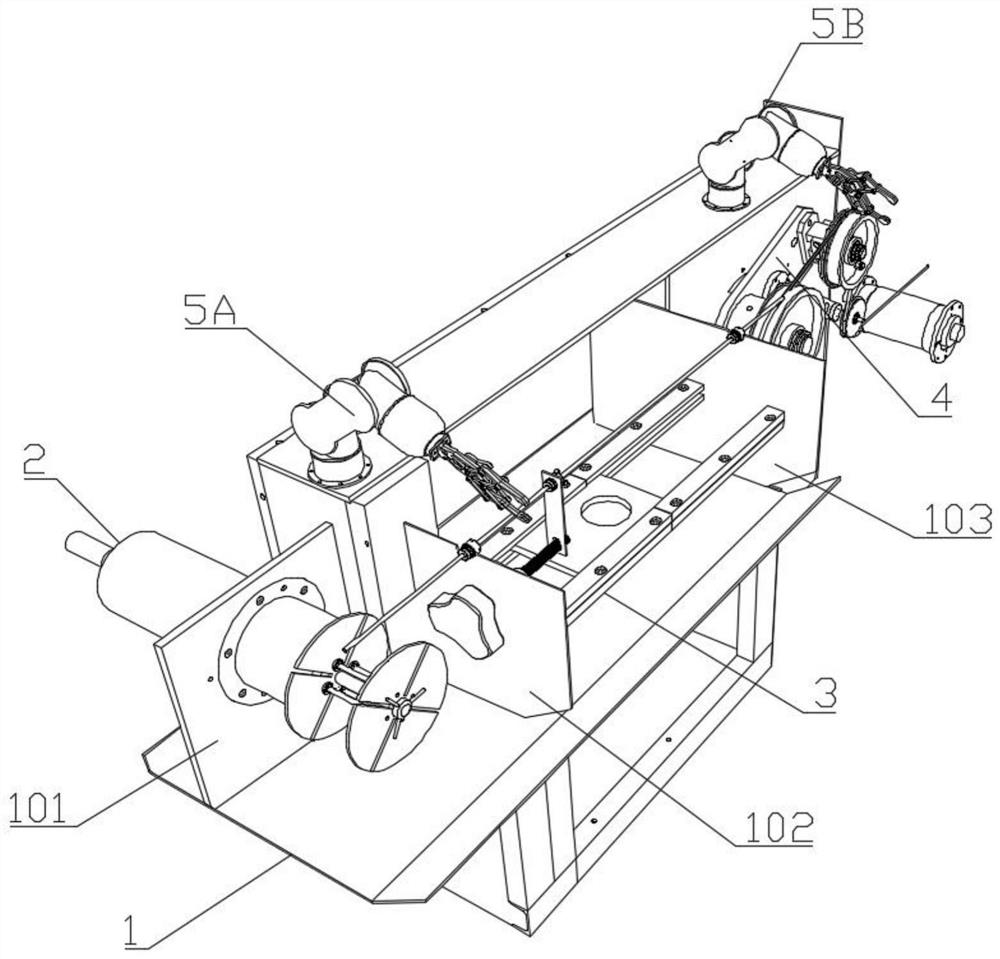

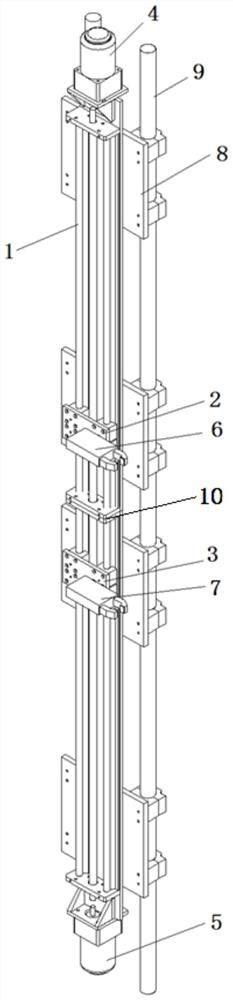

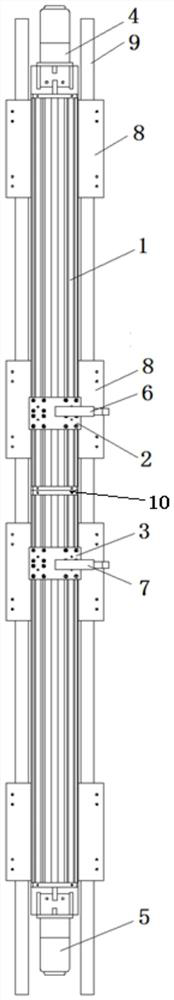

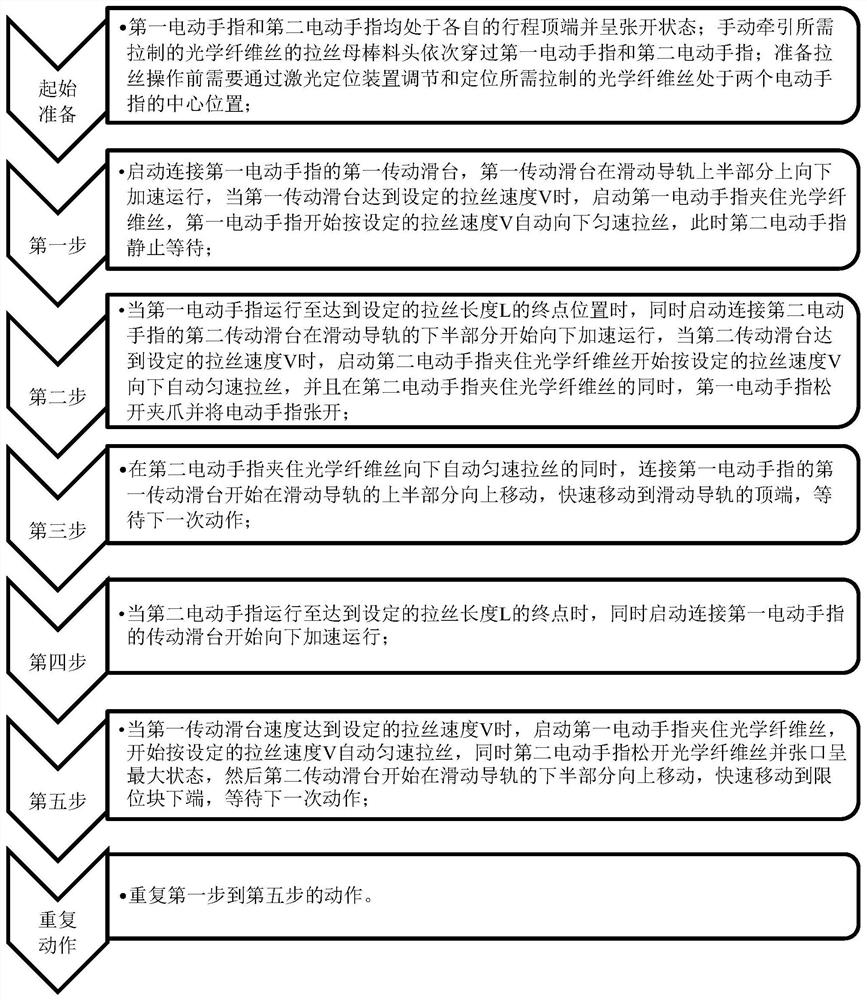

Nondestructive vertical automatic wire drawing method for optical fibers

ActiveCN111943501AThe drawing process is stableReduces surface contact and cortex wearGlass fibre drawing apparatusEngineeringElectrical and Electronics engineering

The invention discloses a nondestructive vertical automatic wire drawing method for optical fibers. The method comprises the steps that a first electric finger and a second electric finger are respectively positioned at the top ends of respective strokes at the beginning, a first transmission sliding table accelerates downwards and starts the first electric finger to clamp an optical fiber wire atthe beginning of wire drawing, the first electric finger loosens a clamping jaw when the first transmission sliding table moves to an end point, a second transmission sliding table begins to accelerate downwards and starts the second electric finger to clamp the optical fiber wire for downward wire drawing at the same time, and the first transmission sliding table quickly moves to the top end ofa sliding guide rail at the moment; and when the second electric finger moves to the end point of a wire drawing length L, the second electric finger is loosened, the first transmission sliding tableis started to begin downward accelerated operation, the first electric finger is started to perform automatic wire drawing, and then the second transmission sliding table starts to quickly move to thetop end of the stroke to wait for repeating of the next action. Through the nondestructive automatic wire drawing method, the surface contact and skin layer damage of the optical fiber are reduced, and the drawing surface quality of the optical fiber and the stability of a wire diameter are improved.

Owner:CHINA BUILDING MATERIALS ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com