Optical fiber heating furnace exhaust recovery and purification recycling system and method thereof

A tail gas recovery and heating furnace technology, applied in chemical instruments and methods, inert gas compounds, inorganic chemistry, etc., can solve problems affecting system work efficiency, reduce helium loss, improve work efficiency, and increase helium recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following description is used to disclose the present invention so that those skilled in the art can implement the present invention. The preferred embodiments in the following description are only examples, and those skilled in the art can think of other obvious variations.

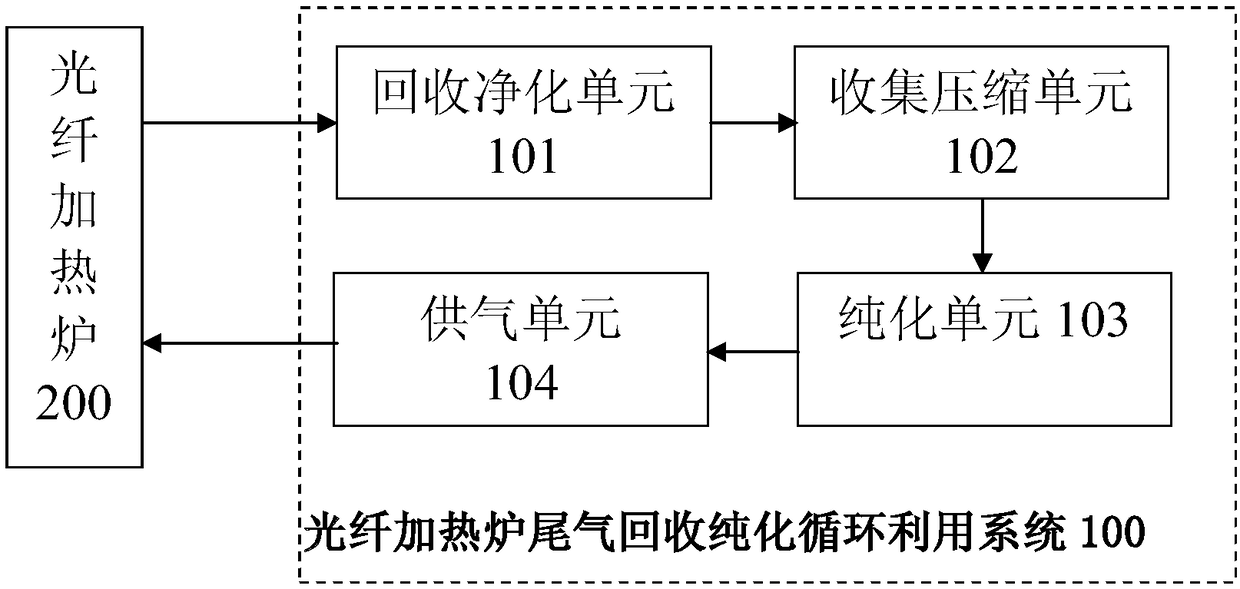

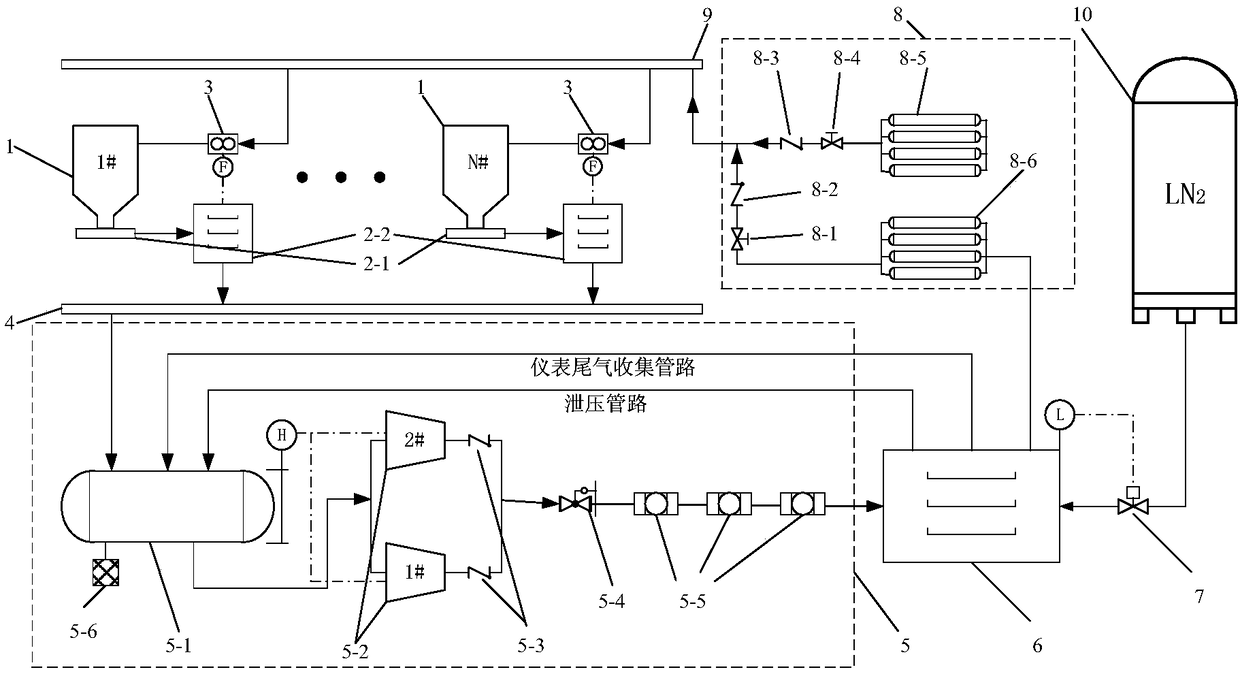

[0020] Such as Figure 1 to Figure 3 As shown, the fiber optic heating furnace tail gas recovery and purification recycling system 100 provided in this embodiment is used to recover and recycle the helium-rich tail gas of the fiber optic heating furnace 200. It includes a recovery and purification unit 101, a collection and compression unit 102, a purification unit 103, and a supply unit. 气unit 104.

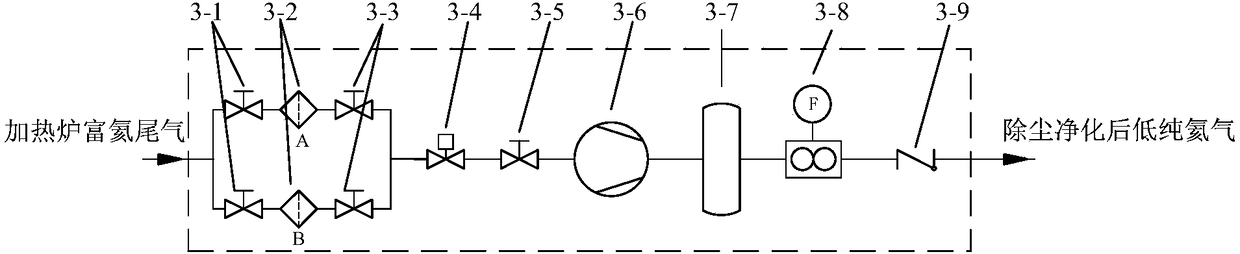

[0021] The recovery and purification unit 101 is used to recover and purify waste helium from the fiber optic heating furnace 200. The recovery and purification unit 101 includes a recovery tool 2-1, a filtering and purification device 2-2, and an exhaust gas collecting pipe 4. The fiber optic heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com