Nondestructive vertical automatic wire drawing method for optical fibers

An optical fiber, non-damaging technology, applied in glass fiber drawing devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as uneven diameter of twisted wire drawing, scalding rubber drawing wheel, slipping of optical fiber wire, etc., to achieve wire drawing Process stabilization, reduced surface contact and skin wear, improved surface quality and better results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

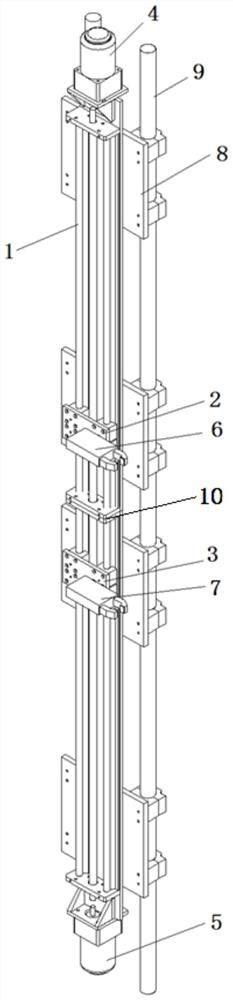

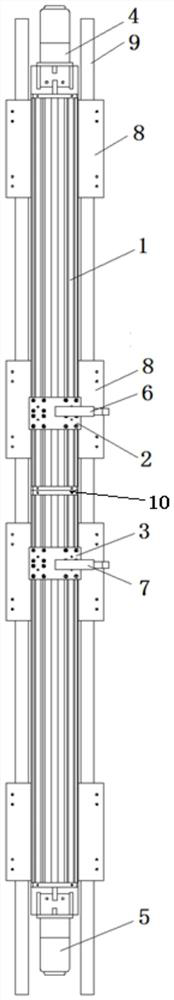

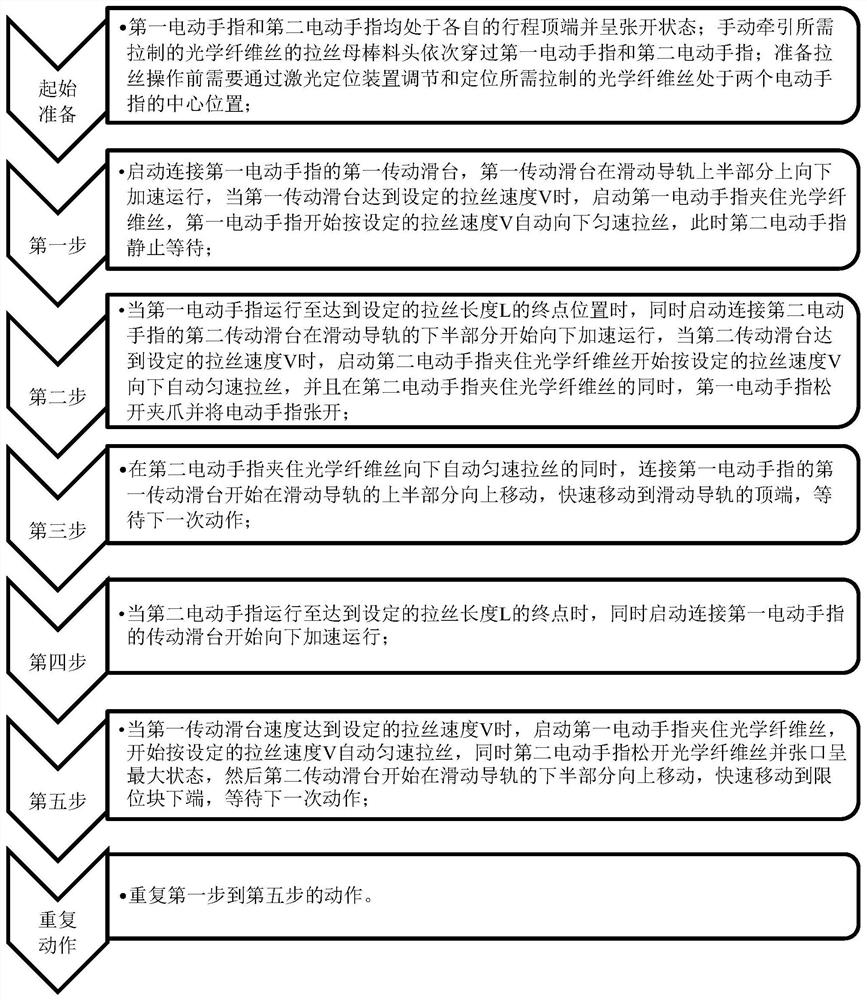

[0063] see image 3 , a method for non-damaging vertical automatic drawing of optical fibers, comprising the following steps:

[0064] Initial preparation: Both the first electric finger and the second electric finger are at the top of their respective strokes and their openings are at the maximum state; the drawing head of the optical fiber to be drawn is manually pulled through the first electric finger and the second electric finger in turn. Fingers: before the wire drawing operation, the laser positioning device needs to be used to adjust and position the optical fiber wire to be drawn in the center of the two electric fingers;

[0065] The first electric finger is at the top of the stroke of the upper half of the sliding guide rail, and the second electric finger is at the top of the stroke of the lower half of the sliding guide rail. The sliding guide rail is divided into the upper half and the lower half by the limit block; the length of the sliding guide rail is 1600mm...

Embodiment 2

[0075] The steps are the same as in Example 1, except that the drawing speed V is 70 mm per second, the drawing distance L is 800 mm, and the length of the sliding guide rail is 2000 mm.

Embodiment 3

[0077] The steps are the same as in Example 1, except that the wire drawing speed V is 20 mm per second, the wire drawing distance L is 400 mm, and the length of the sliding guide rail is 1200 mm.

[0078] The invention sets, adjusts and controls the wire drawing speed of the transmission slide, the return speed of the transmission slide, and the wire drawing length of the transmission slide through an intelligent control system; an optical fiber non-damage automatic wire drawing system of the present invention is used for automatic wire drawing, The splint of the electric finger is used to clamp the optical fiber. The splint of the electric finger is in contact with the optical fiber through point contact, forming a point-contact drawing traction method. The transmission slide and the electric finger are not in contact with the optical fiber during the traction process. The contact or touch of other positions of the filament reduces the contact with the optical fiber filament,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Ellipticity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com