Ball grinding mill bearing bush lubricating oil and manufacturing method thereof

A lubricating oil and ball mill technology, applied in the field of lubricating oil, can solve problems such as poor lubrication of ball mill bearing bushes, and achieve the effects of easy promotion, reduced wear, and firm film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

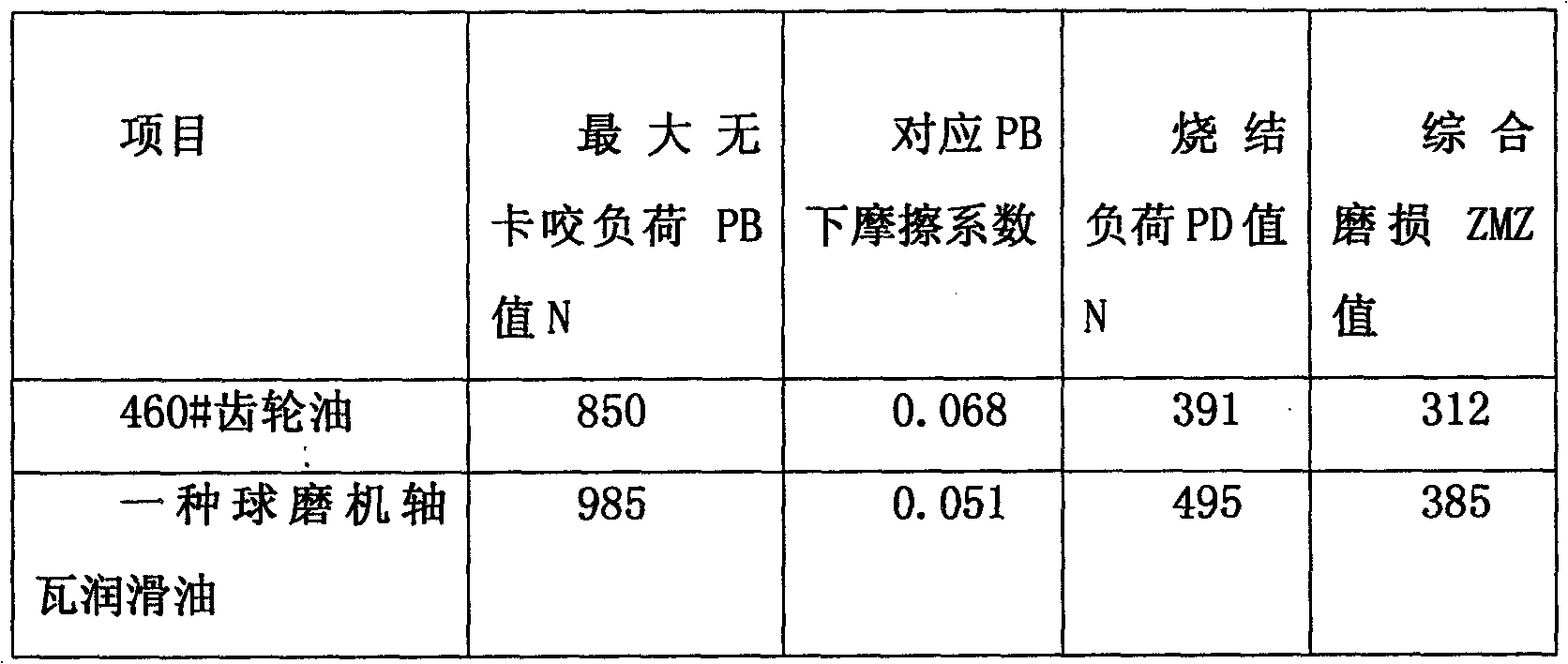

Image

Examples

Embodiment 1

[0044] A ball mill bearing bush lubricating oil is composed of the following components by mass percentage: 60% of mineral lubricating oil, 32% of polyester synthetic oil, 0.1% of tackifier, 3% of organic molybdenum composite additive, 3% of T306 additive, T202 anti- Oxygen agent 0.5%, T551 metal deactivator 0.8%, T704 rust inhibitor 0.6%, the sum of the components is 100%.

[0045] A method for manufacturing ball mill bearing lubricating oil, the specific process steps are: first pour 50% of the total mass of mineral lubricating oil into a closed reaction kettle with a stirrer and heat it to 80°C according to the mass percentage, and then pre-crushed Add the ethylene-propylene rubber into the reaction kettle and stir for 2.5 hours; until it is completely dissolved, add 60% of the total mass of polyester synthetic oil, stir and cool down to 70°C, then add organic molybdenum composite additives, stir and dissolve for 1.8 hours, until fully dissolved Disperse, then add the remai...

Embodiment 2

[0048] A ball mill bearing bush lubricating oil is composed of the following components by mass percentage: 55% of mineral lubricating oil, 36% of polyester synthetic oil, 0.08% of tackifier, 4% of organic molybdenum composite additive, 3% of T306 additive, T202 anti- Oxygen agent 0.5%, T551 metal deactivator 0.8%, T704 rust inhibitor 0.62%, the sum of the components is 100%.

[0049] A method for manufacturing ball mill bearing lubricating oil, the specific process steps are: first pour 50% of the total mass of mineral lubricating oil into a closed reaction kettle with a stirrer and heat it to 80°C according to the mass percentage, and then pre-crushed Add the ethylene-propylene rubber into the reaction kettle and stir for 2 hours; until it is completely dissolved, add 60% of the total mass of polyester synthetic oil, stir and cool down to 70°C, then add organic molybdenum composite additives, stir and dissolve for 1.5 hours, until fully dissolved Disperse, then add the remai...

Embodiment 3

[0052]A ball mill bearing bush lubricating oil is composed of the following components by mass percentage: 65% of mineral lubricating oil, 26% of polyester synthetic oil, 0.12% of tackifier, 4% of organic molybdenum composite additive, 3% of T306 additive, T202 anti- Oxygen agent 0.5%, T551 metal deactivator 0.7%, T704 rust inhibitor 0.68%, the sum of the components is 100%.

[0053] A method for manufacturing ball mill bearing lubricating oil, the specific process steps are: first pour 50% of the total mass of mineral lubricating oil into a closed reaction kettle with a stirrer and heat it to 80°C according to the mass percentage, and then pre-crushed Add the ethylene-propylene rubber into the reaction kettle and stir for 3 hours; until it is completely dissolved, add 60% of the total mass of polyester synthetic oil, stir and cool down to 70°C, then add organic molybdenum composite additives, stir and dissolve for 2 hours, until fully dissolved Disperse, then add the remainin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com