Shredded squid drawing machine and drawing method thereof

A technology of wire drawing machine and squid shreds, which is applied in the field of squid wire drawing machine and its wire drawing, can solve problems such as squid shreds breaking and affecting product quality, and achieve the effects of improving quality, improving wire drawing efficiency, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

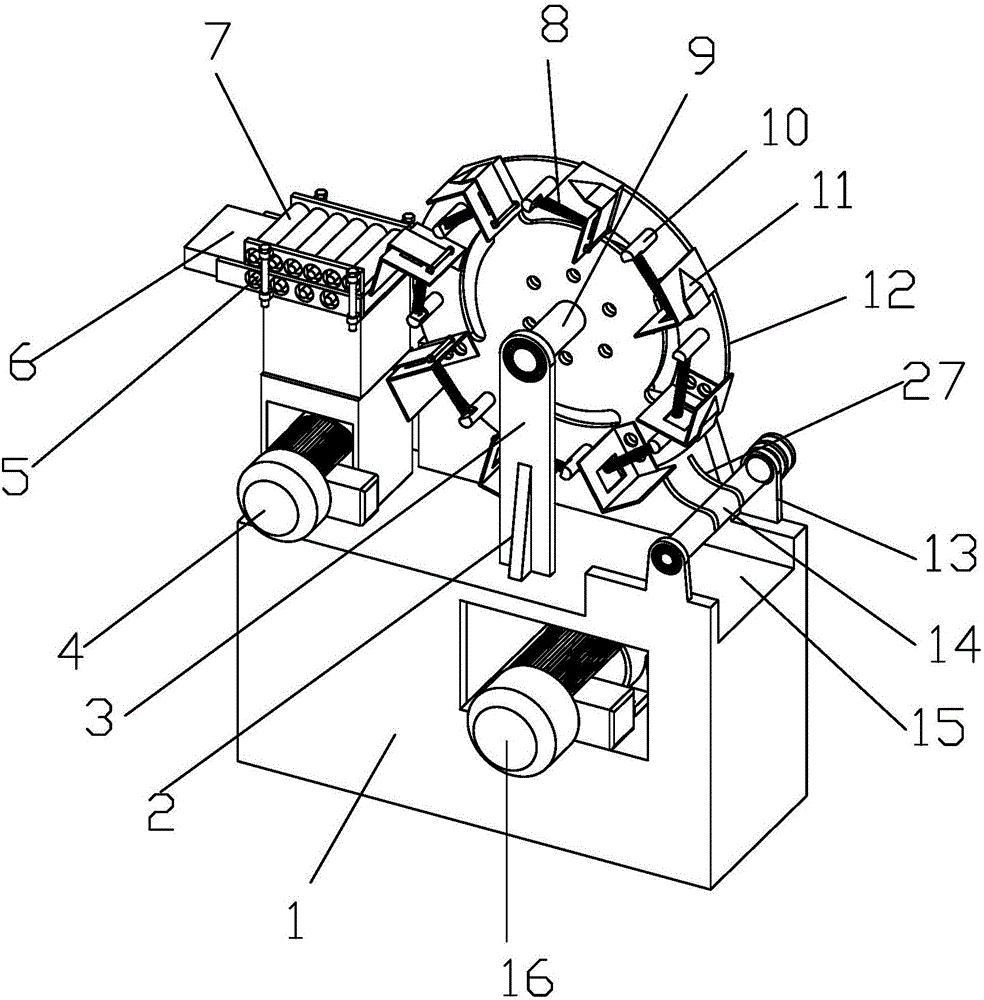

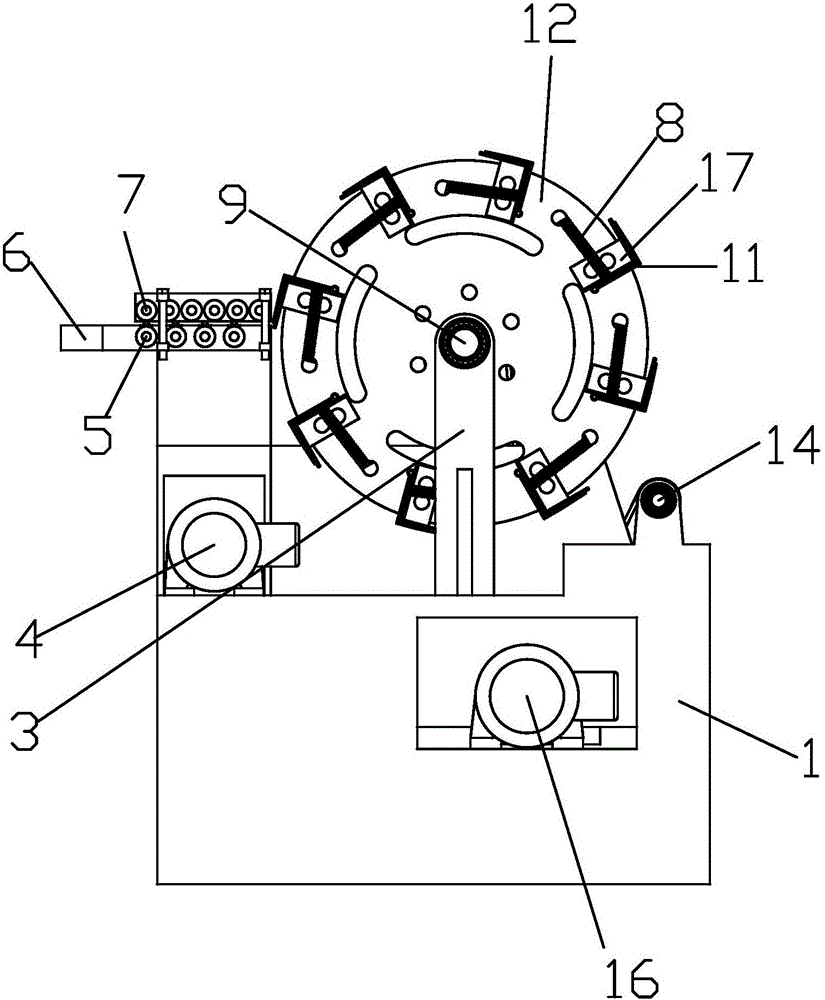

[0038] Such as Figure 1-3 Shown squid wire drawing machine, it comprises base 1, and one end of base 1 is provided with feeding port 6, and feeding port 6 is connected with transmission mechanism, and base 1 is also provided with drawing mechanism, and drawing mechanism includes being arranged on base 1 and Correspondingly provided with the first bracket 3, the first rotating shaft 9 that rotates towards the direction of the transmission mechanism is provided between the first brackets 3, the first rotating shaft 9 is provided with a turntable 12, and the spacer ring on the turntable 12 is provided with a cutter chassis 17, and the cutter chassis 17 There is a wire drawing knife 11 on it, the outlet end of the transmission mechanism is close to the blade of the wire drawing knife 11 , and the end of the base 1 far away from the feed port 6 is provided with a discharge port 15 .

[0039] Further, such as Figure 4-5 The shown tool chassis 17 includes a first connecting portio...

Embodiment 2

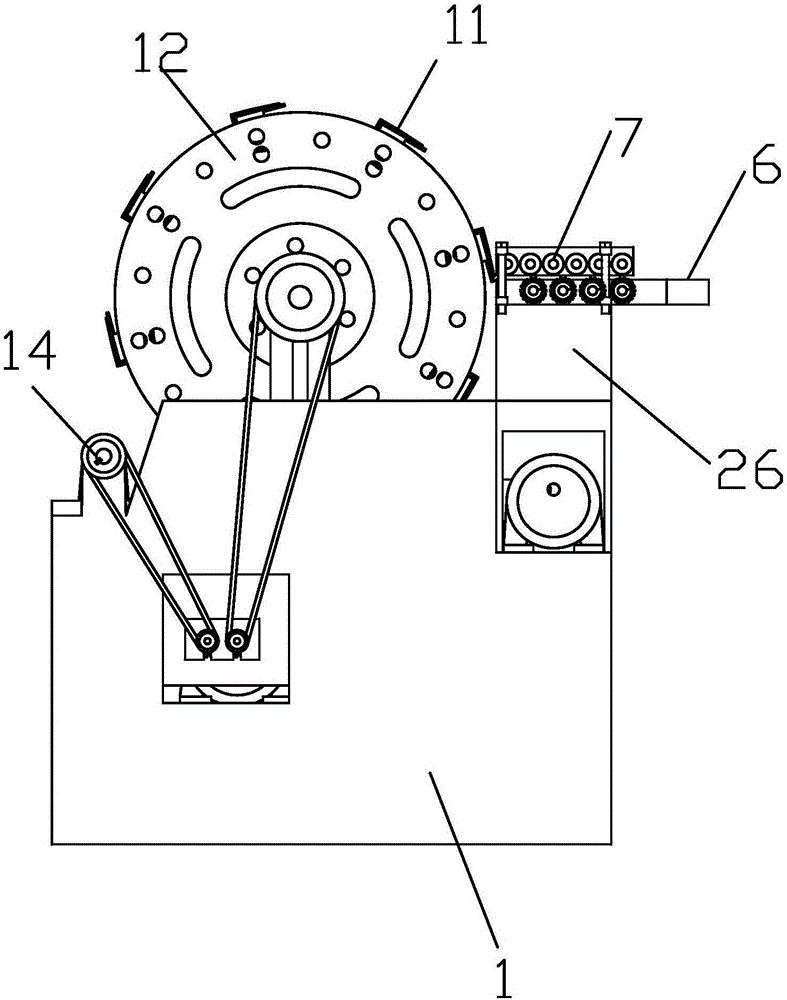

[0054] The difference from Embodiment 1 is that a double-station squid wire drawing machine is provided on the same base.

[0055] Such as Figure 6 and 7 In the described double-station squid wire drawing machine, it can be seen that the No. 1 feed port 61 and the No. 2 feed port 62 are arranged side by side above the base, wherein the No. 1 feed port 61 is connected with the No. 1 transmission mechanism, and the No. 1 transmission mechanism It is connected with the No. 1 wire drawing mechanism, the No. 2 feed port 62 is connected with the No. 2 transmission mechanism, and the No. 2 transmission mechanism is connected with the No. 2 wire drawing mechanism. It is only necessary to set the wire-removing shrapnel 27 at positions corresponding to the No. 1 wire drawing knife 111 and the No. 2 wire drawing 112 . The structure is simple like this, and only one set of wire-removing mechanism is needed to complete the wire-removing operation for two sets of wire-drawing mechanisms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com