Basalt fibers applied to epoxy prepreg and production method of basalt fibers

A technology of basalt fiber and production method, which is applied in the field of fiber production, can solve the problems of lower production efficiency, degumming of epoxy prepreg, slow development of sizing agent, etc., and achieve the goal of improving film forming performance, good winding performance and reducing wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

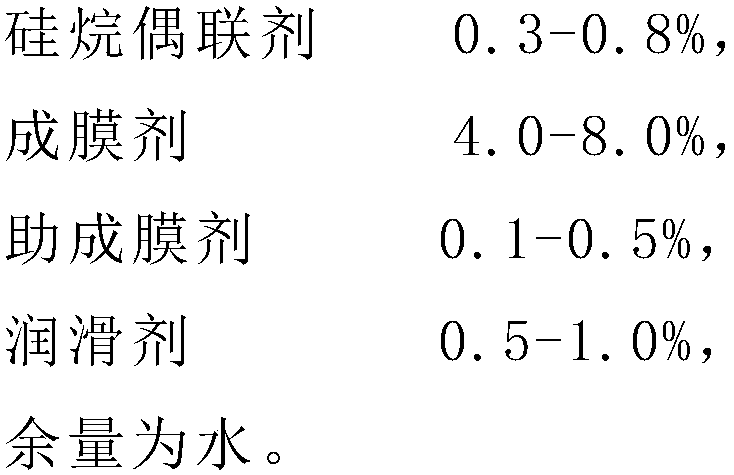

[0031] A production method of basalt fiber applied to epoxy prepreg, the steps are as follows: ① Grinding basalt ore into 500-mesh powder. ② When charging the stove, add 5kg of the powder every 10 minutes. ③For wire drawing, use a 600-hole furnace, set the flow rate to 20kg / h, and set the head speed to 2000 rpm, which can draw basalt fibers of 16 microns and 325tex. ④ Treat the surface of the basalt fiber with a sizing agent of a specific formula, and the sizing agent formula is:

[0032] Silane coupling agent with brand KH560: 0.3kg;

[0033] E51 bisphenol A epoxy resin emulsion: 6.0kg;

[0034] Cationic epoxy resin emulsion with brand NBR-290: 0.3kg;

[0035] Zwitterionic surfactant with brand NBR-1070: 0.5kg;

[0036] Deionized water: 92.9kg.

[0037] ⑤ To dry the yarn, raise the temperature from normal temperature to 95°C, heat it up to 125°C after 2 hours of heat preservation, and cool it to room temperature after 3 hours of heat preservation. 6. Winding, set the dr...

Embodiment 2

[0042] A production method of basalt fiber applied to epoxy prepreg, the steps are as follows: ① Grinding basalt ore into 100-mesh powder. ② When charging the stove, add 7kg of the powder every 20 minutes. ③For wire drawing, use a 600-hole furnace, set the flow rate to 28kg / h, and set the head speed to 2800 rpm, which can draw basalt fibers of 16 microns and 325tex. ④ Treat the surface of the basalt fiber with a sizing agent of a specific formula, and the sizing agent formula is:

[0043] Silane coupling agent with brand KH560: 0.8kg;

[0044] E51 bisphenol A epoxy resin emulsion: 4kg;

[0045] Cationic epoxy resin emulsion with brand NBR-290: 0.1kg;

[0046] The brand is the zwitterionic surfactant of NBR-1070: 1.0kg;

[0047] Deionized water: 94.1kg.

[0048] ⑤ To dry yarn, raise the temperature from normal temperature to 90°C, heat it up to 120°C after 2 hours of heat preservation, and cool it to room temperature after 3 hours of heat preservation, with a temperature r...

Embodiment 3

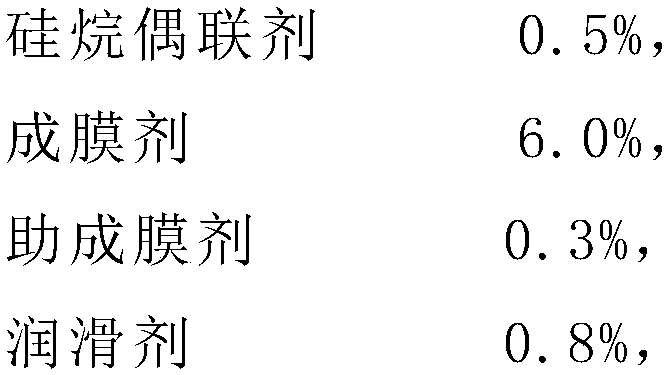

[0052]A production method of basalt fiber applied to epoxy prepreg, the steps are as follows: ① Grinding basalt ore into 1000 mesh powder. ② When charging the stove, add 6kg of the powder every 15 minutes. ③For wire drawing, use an 800-hole hearth, set the flow rate to 24kg / h, and set the head speed to 3000 rpm, which can draw basalt fibers of 13 microns and 264tex. ④ Treat the surface of the basalt fiber with a sizing agent of a specific formula, and the sizing agent formula is:

[0053] KH560: 0.5kg;

[0054] E44 emulsion: 8.0kg;

[0055] NBR-290 (manufacturer Sinoma Science and Technology Special Fiber Division): 0.5kg;

[0056] Zwitterionic surfactant with brand name NBR-1070: 0.8kg;

[0057] Deionized water: 90.2kg.

[0058] ⑤ To dry the yarn, raise the temperature from normal temperature to 100°C, heat it for 3 hours, then heat it up to 140°C, hold it for 2 hours, and cool it to room temperature. 6. Winding, set the drum speed to be 7000 rpm, so that two strands of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com