Dispersive rotary type liquid copper alloy casting purification device and filtering casting process thereof

A technology of alloy casting and purification device, which is applied in manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of inconvenient casting of liquid copper alloy and blocked flow of liquid copper alloy, achieve ingenious design structure and process, and avoid clogging of filter residues. , the effect of high centrifugal speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

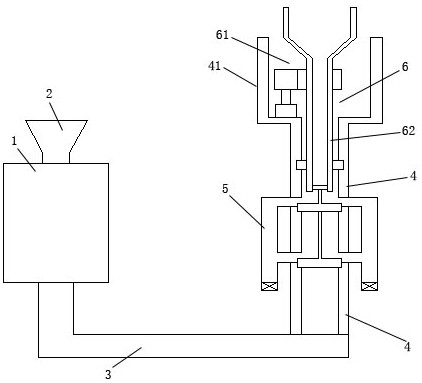

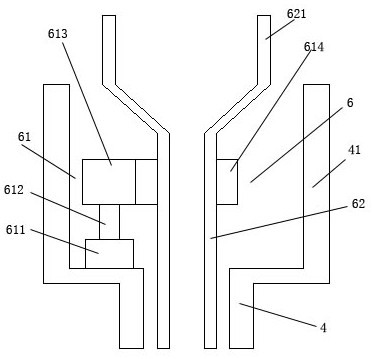

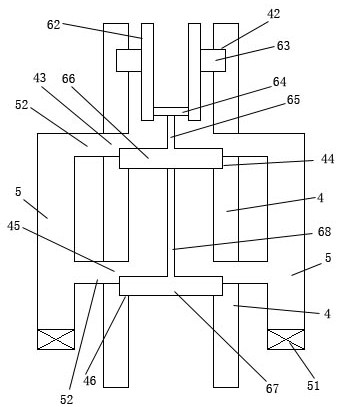

[0016] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] Such as Figures 1 to 3 As shown, a dispersive rotary liquid copper alloy casting purification device includes an ingot 1, a riser 2, a bottom horizontal pipe body 3, a longitudinal pipe body 4, a dispersed rotary filter mechanism 6, and a slag collection ring body 5; A riser 2 is installed in the middle of the upper end of the ingot 1; a bottom transverse pipe body 3 is installed on one side of the lower end of the ingot 1; a longitudinal pipe body 4 is installed above the outer end of the bottom transverse pipe body 3; the dispersed rotary filter Mechanism 6 comprises driving mechanism 61, rotating liquid inlet pipe 62, clamping ring body 63, connecting cross bar 64, connecting longitudinal bar 65, upper ceramic filter screen 66, lower ceramic filter screen 67; The minimum diameter of the hole is greater than the maximum diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com