Diverging device of differentiated fine concentrator main machine

A differentiated and refined technology, applied in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc., can solve problems such as large dust pollution, poor mineral particle classification effect, and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

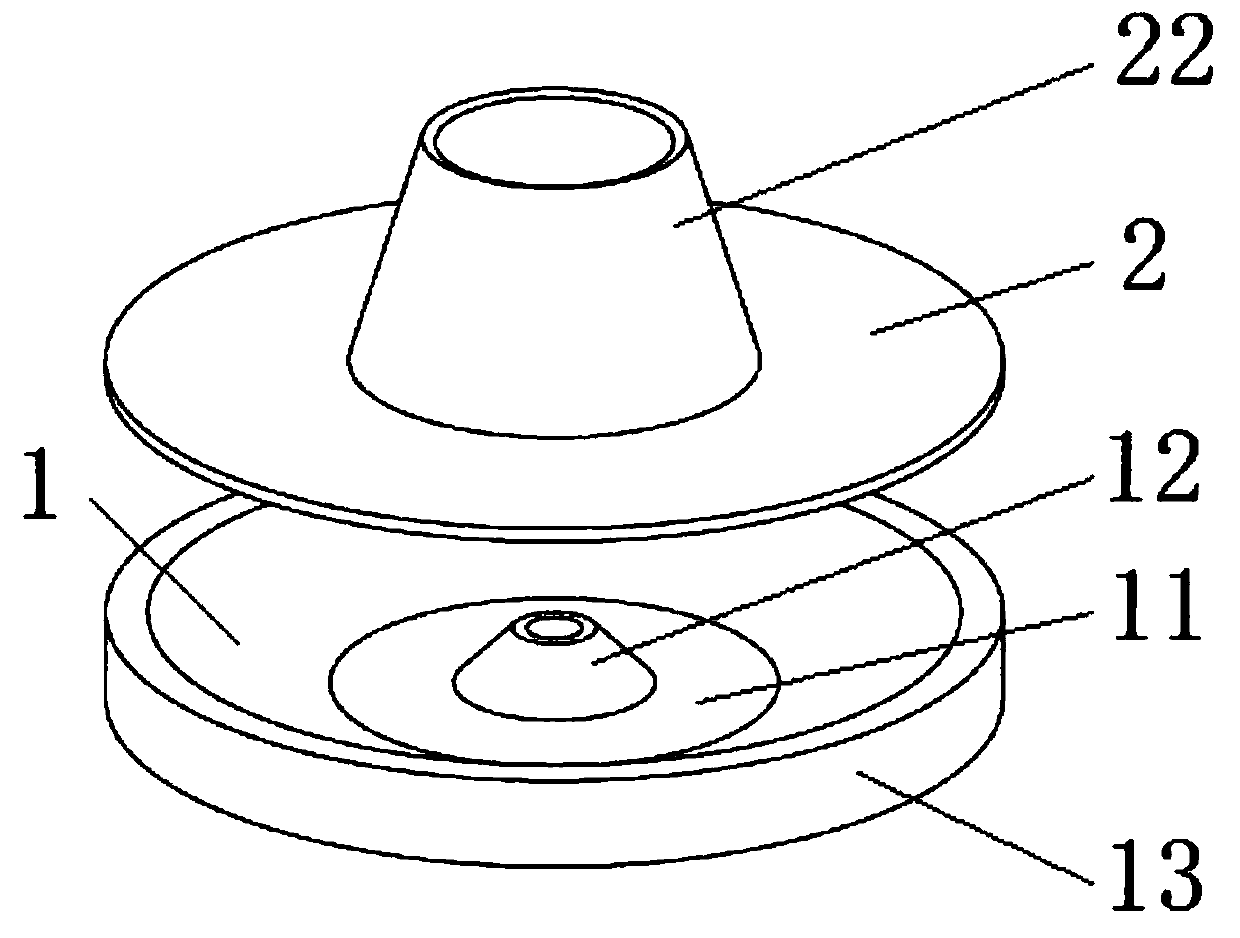

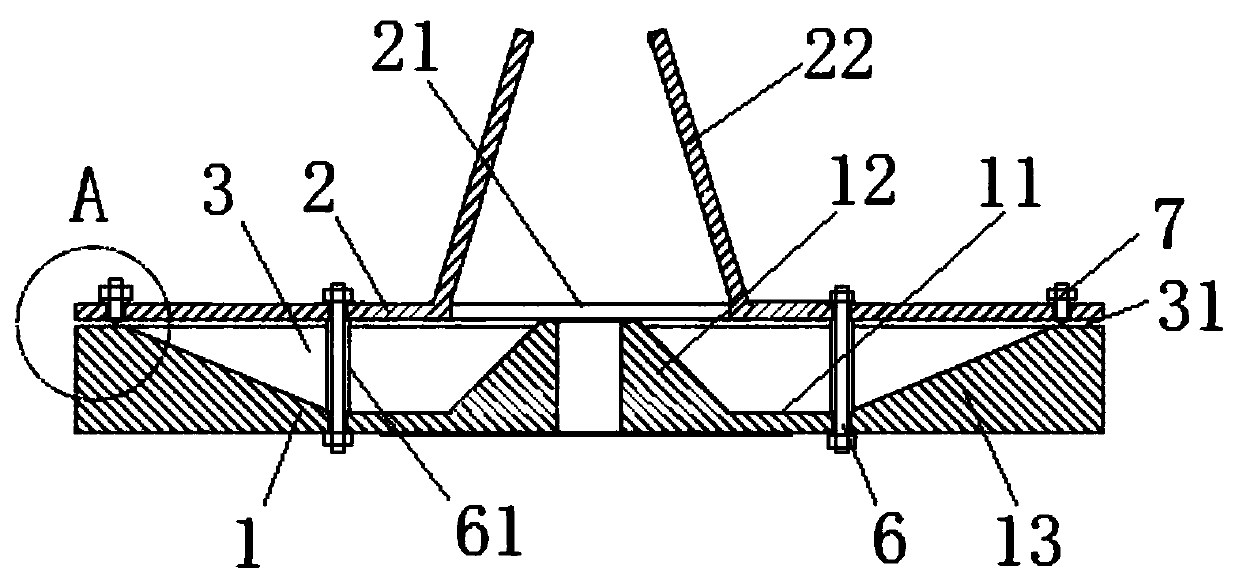

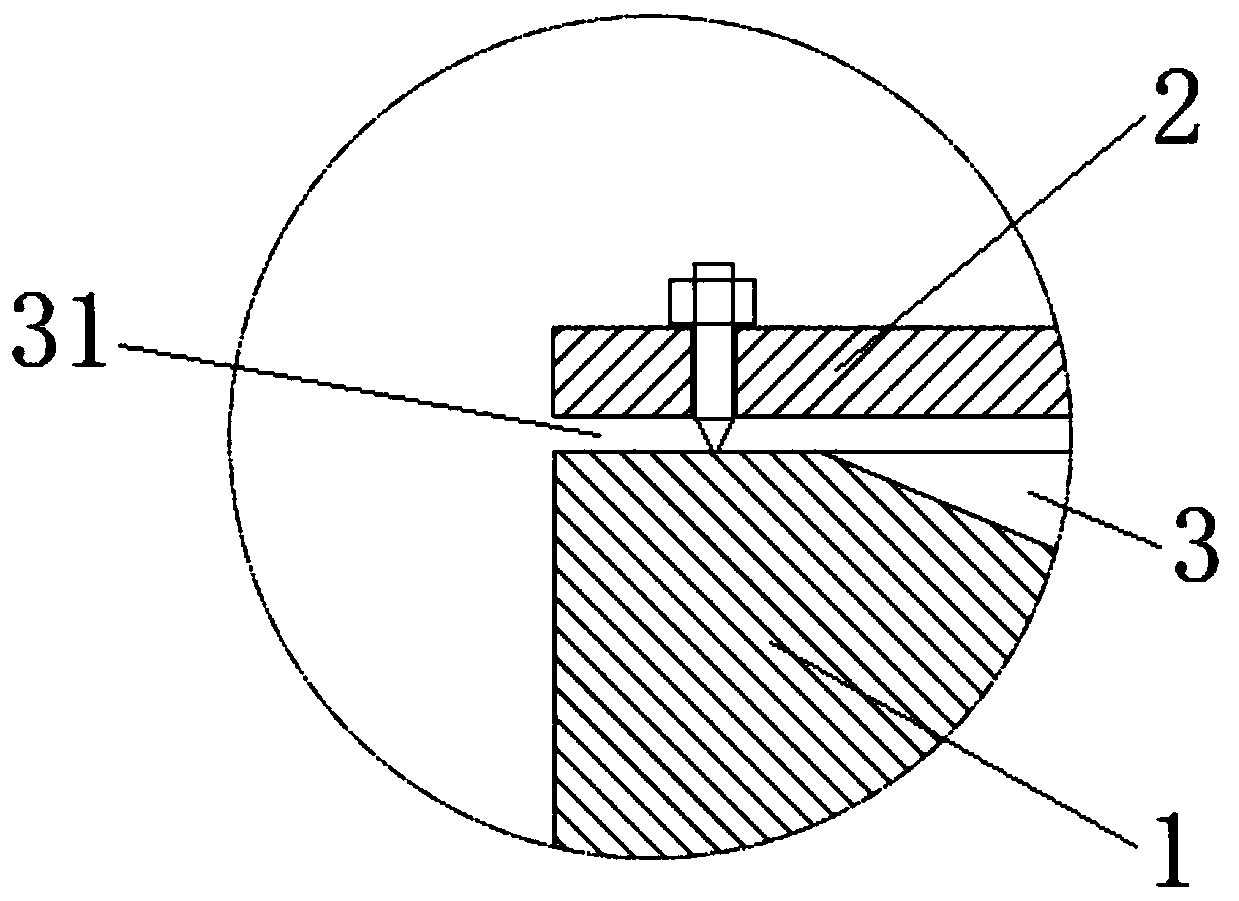

[0032] Such as figure 1 As shown, a diffuser device of a differentiated fine mineral processing main engine is installed in a differentiated fine mineral processing main engine, and is used to throw mineral particles horizontally. A feeding pipe 8 is arranged above it, and a material classification sleeve 9 is arranged below it. Such as figure 1 and figure 2 As shown, the receiving tray 1 comprises a circular chassis 11, a round table 12 is installed in the middle of the circular chassis 11, and a circular wall 13 concentric with the circular chassis 11 is also installed, and the outer ring of the circular wall 13 is perpendicular to the chassis 11 , the outer diameter is the same as the circular chassis 11, the width is the same as the height of the circular platform 12, the section of the ring wall 13 is a right-angled trapezoid whose bottom edge is parallel to the circular chassis 11, and the longer lower bottom edge contacts the circular chassis 11; A gap 31 is formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com