Power nacelle

A pod and power technology, applied in the field of aerospace structures, can solve the problems of many parts of the power pod, the inability to provide thermal insulation for internal equipment, complex assembly process, etc., to achieve the effect of ensuring the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

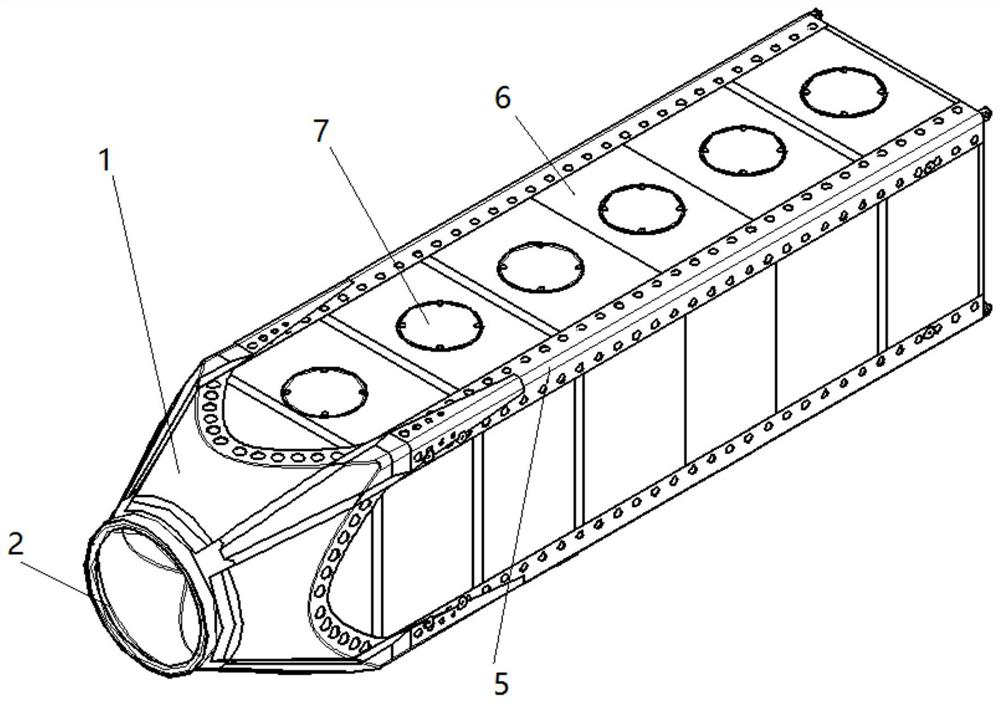

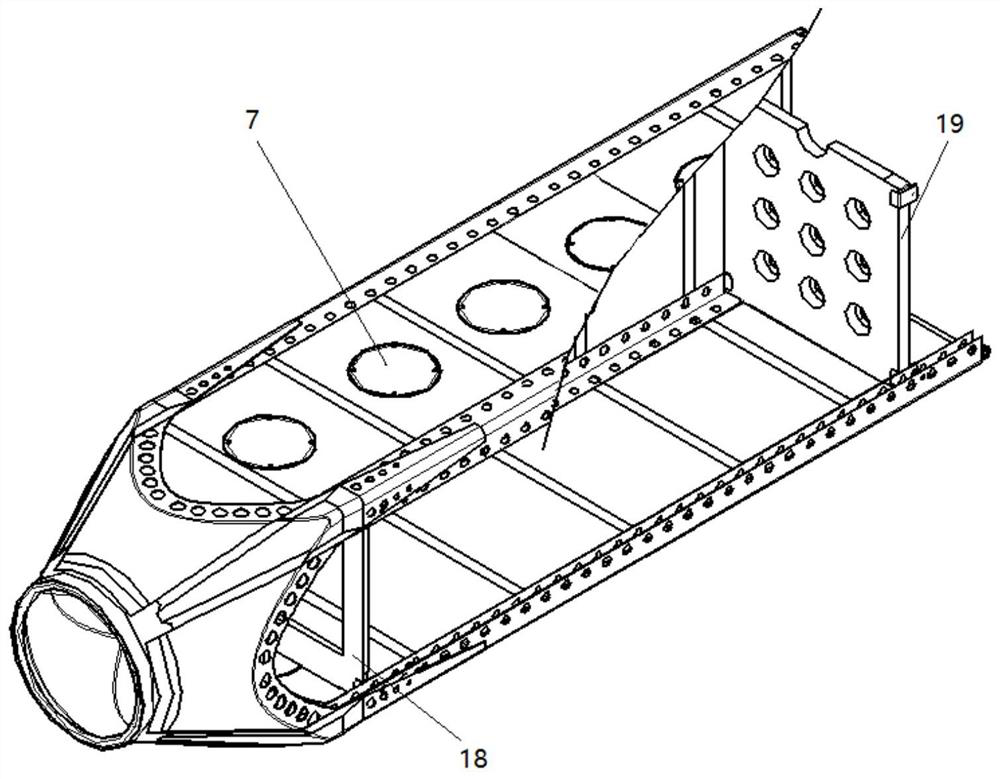

[0082]Such asFigures 1 to 14As shown, the present invention provides a power champion, including

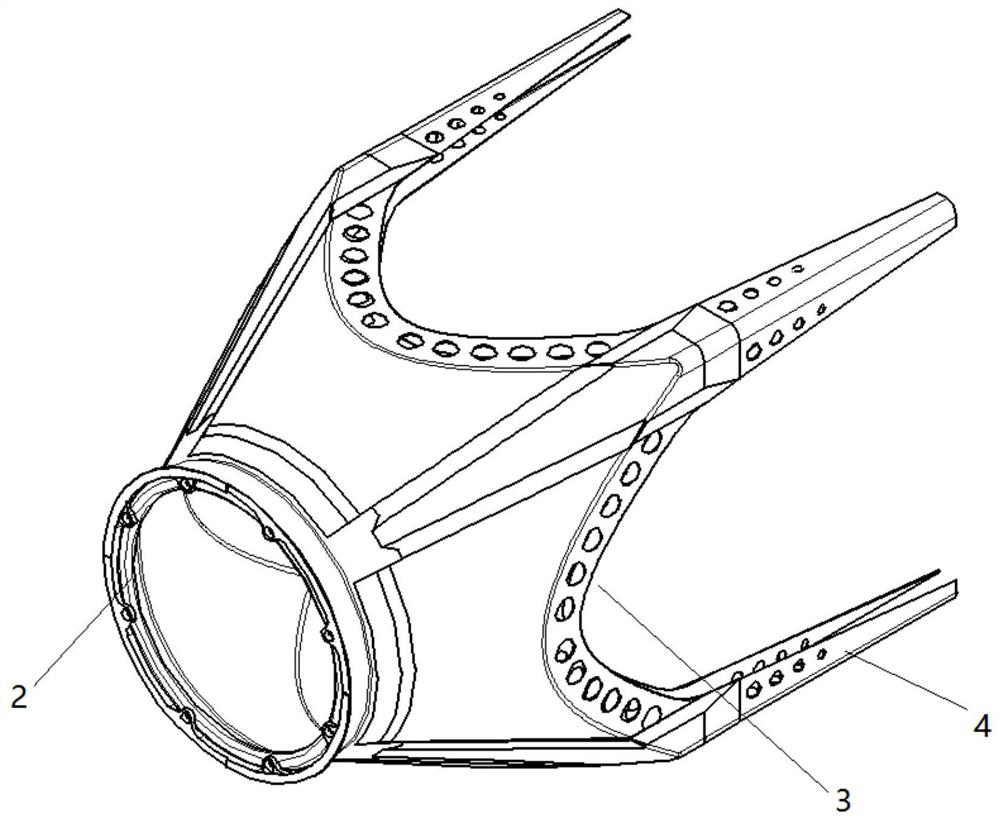

[0083]The head cone 1, the head cone 1 is a cone-shaped structure, and the front end of the head cone 1 has a first opening 2, and the end of the head cone 1 is opened 3, and the tail end of the head cone is integrated with multiple first. The connecting portion 4, the first connecting portion 4 extends toward the tail end of the head cone 1;

[0084]The plurality of fork ear tone 5, one end of the fork ear tone 5 is bonded to the first connecting portion 4, and the other end of the fork ear tilt rod 5 is used to connect to the body;

[0085]The plurality of panels 6 are bonded to the end of the head cone 1 and the side surface of the ferr gear rod 5, and the plurality of panels 6 are formed into a cylindrical structure with the plurality of fork ear tilt rods 5 and the head cone 1, and there is a mounting hole 7 on the panel 7. ;

[0086]The cover 8 is mounted with the mounting hole 7.

[0087]In th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap