Reduction gearbox counterweight energy-saving system for quay crane

An energy-saving system and balance weight technology, applied in the spring mechanism, hoisting device, etc., can solve the problems of the influence of the service life of the hoisting drum, the increase of the hoisting drum, the decrease of the strength of the hoisting drum, etc., to achieve protection Stable operation, simplified winding structure, and the effect of preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

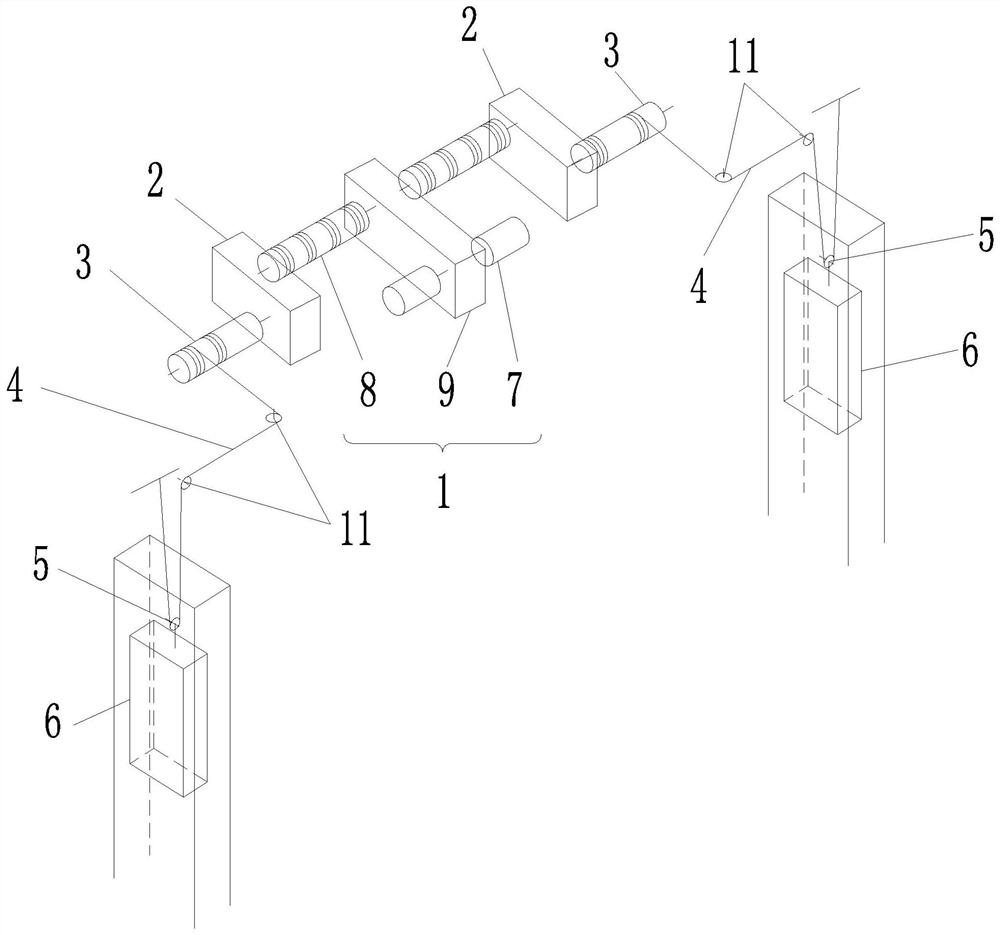

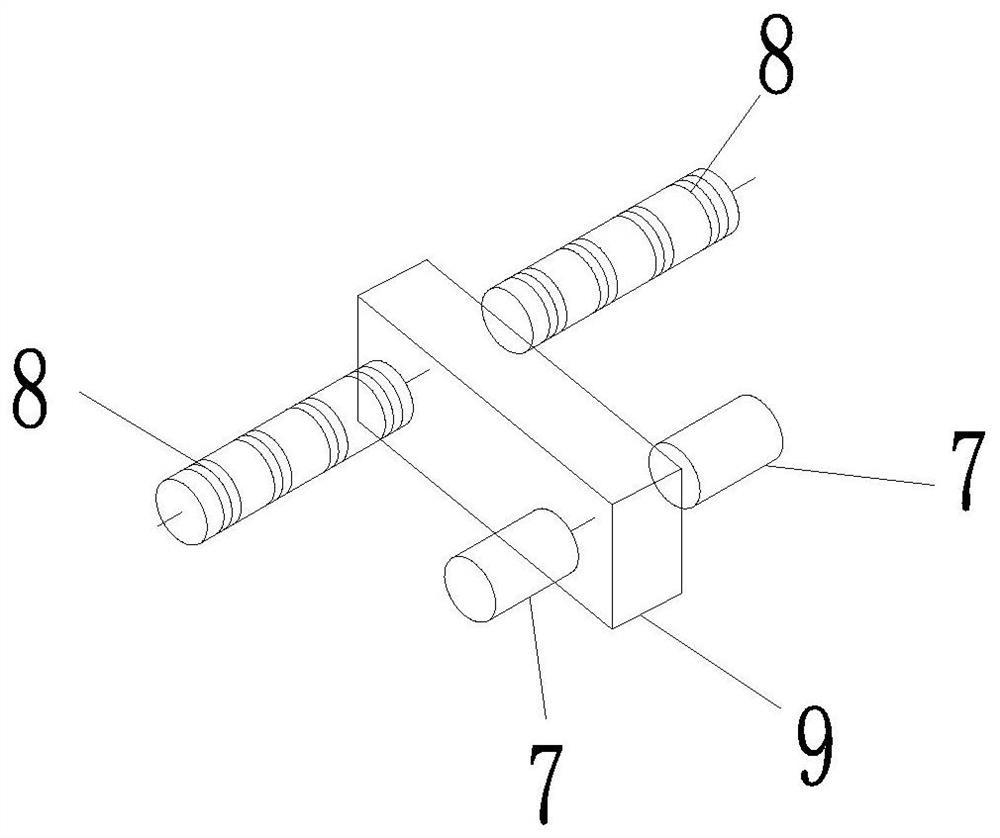

[0020] Embodiment 1 of the present invention: as figure 1 and figure 2 As shown, a gear box balance weight energy-saving system for quay cranes includes a hoisting mechanism 1 , a balance gear box 2 , a balance drum 3 , a balance weight wire rope 4 , a movable pulley 5 and a balance weight 6 . The hoisting mechanism 1 includes a motor 7 , a hoisting reel 8 , a hoisting reduction box 9 and a hoisting wire rope 10 .

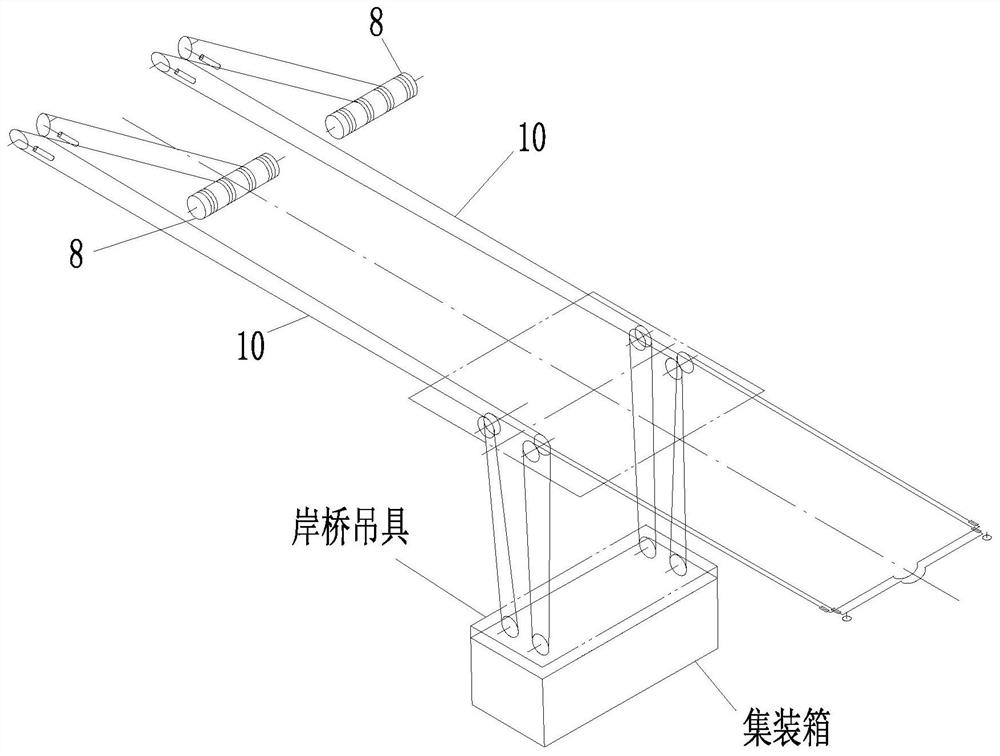

[0021] Such as image 3 As shown, the motor 7, the lifting reduction box 9 and the lifting drum 8 are sequentially connected by transmission, one end of the lifting wire rope 10 is wound on the lifting drum 8, and the other end of the lifting wire rope 10 is wound on the quay bridge On the spreader, the lifting reel 8 rotates, driving the lifting wire rope 10 to pull the quay crane spreader up or down. The quay crane is used for the transshipment of containers. When the container is fully loaded, the weight of the container is relatively large, and the process ...

Embodiment 2

[0023] Embodiment 2 of the present invention: as figure 1 and figure 2 As shown, a gear box balance weight energy-saving system for quay cranes includes a hoisting mechanism 1 , a balance gear box 2 , a balance drum 3 , a balance weight wire rope 4 , a movable pulley 5 and a balance weight 6 . The hoisting mechanism 1 includes a motor 7 , a hoisting reel 8 , a hoisting reduction box 9 and a hoisting wire rope 10 .

[0024] Such as image 3 As shown, the motor 7, the lifting reduction box 9 and the lifting drum 8 are sequentially connected by transmission, one end of the lifting wire rope 10 is wound on the lifting drum 8, and the other end of the lifting wire rope 10 is wound on the quay bridge On the spreader, the lifting reel 8 rotates, driving the lifting wire rope 10 to pull the quay crane spreader up or down. The quay crane is used for the transshipment of containers. When the container is fully loaded, the weight of the container is relatively large, and the process ...

Embodiment 3

[0028] Embodiment 3 of the present invention: as figure 1 and figure 2 As shown, a gear box balance weight energy-saving system for quay cranes includes a hoisting mechanism 1 , a balance gear box 2 , a balance drum 3 , a balance weight wire rope 4 , a movable pulley 5 and a balance weight 6 . The hoisting mechanism 1 includes a motor 7 , a hoisting reel 8 , a hoisting reduction box 9 and a hoisting wire rope 10 .

[0029] Such as image 3 As shown, the motor 7, the lifting reduction box 9 and the lifting drum 8 are sequentially connected by transmission, one end of the lifting wire rope 10 is wound on the lifting drum 8, and the other end of the lifting wire rope 10 is wound on the quay bridge On the spreader, the lifting reel 8 rotates, driving the lifting wire rope 10 to pull the quay crane spreader up or down. The quay crane is used for the transshipment of containers. When the container is fully loaded, the weight of the container is relatively large, and the process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com