A similar modeling method for supercritical carbon dioxide compressor test

A carbon dioxide and compressor technology, applied in the field of impeller machinery, can solve problems such as differences in physical parameters and lack of similar modeling methods, and achieve the effects of reducing test costs, saving test costs, and shortening test cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

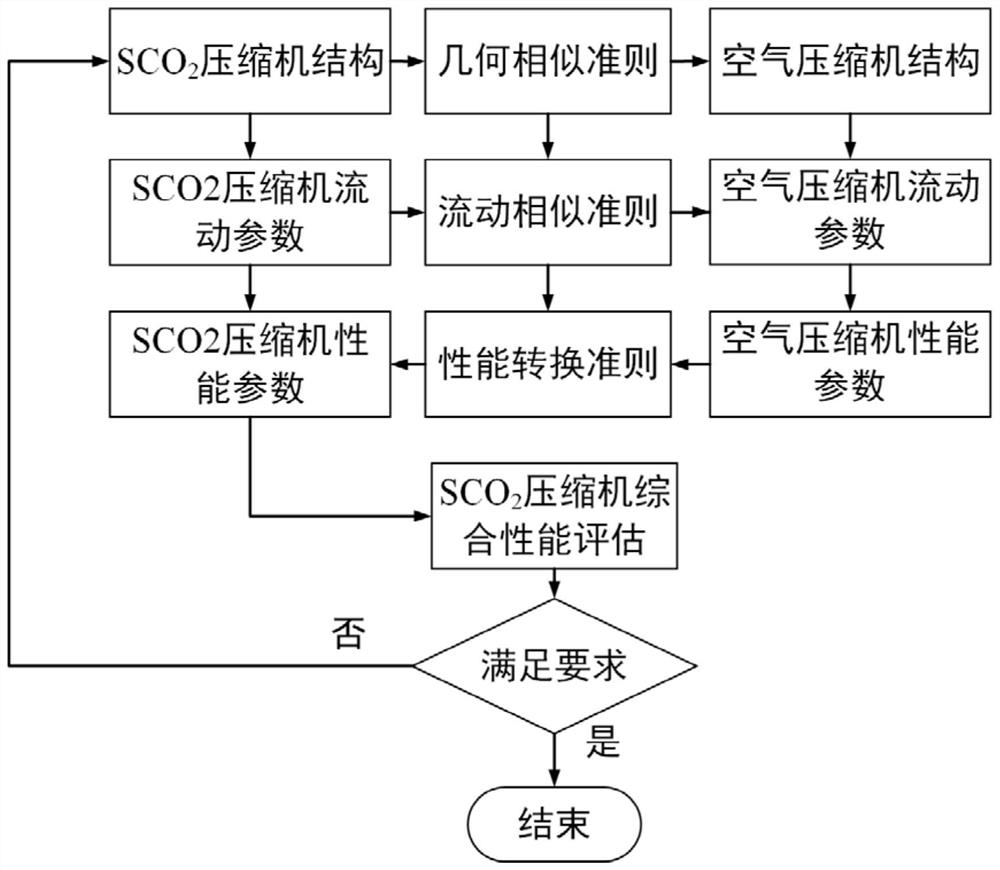

[0055] see figure 1 , figure 1 The flow chart of the similar modeling method for supercritical carbon dioxide compressor test includes four steps of geometric similar modeling, flow similar modeling, compressor performance conversion and comprehensive performance evaluation of supercritical carbon dioxide-air compressor.

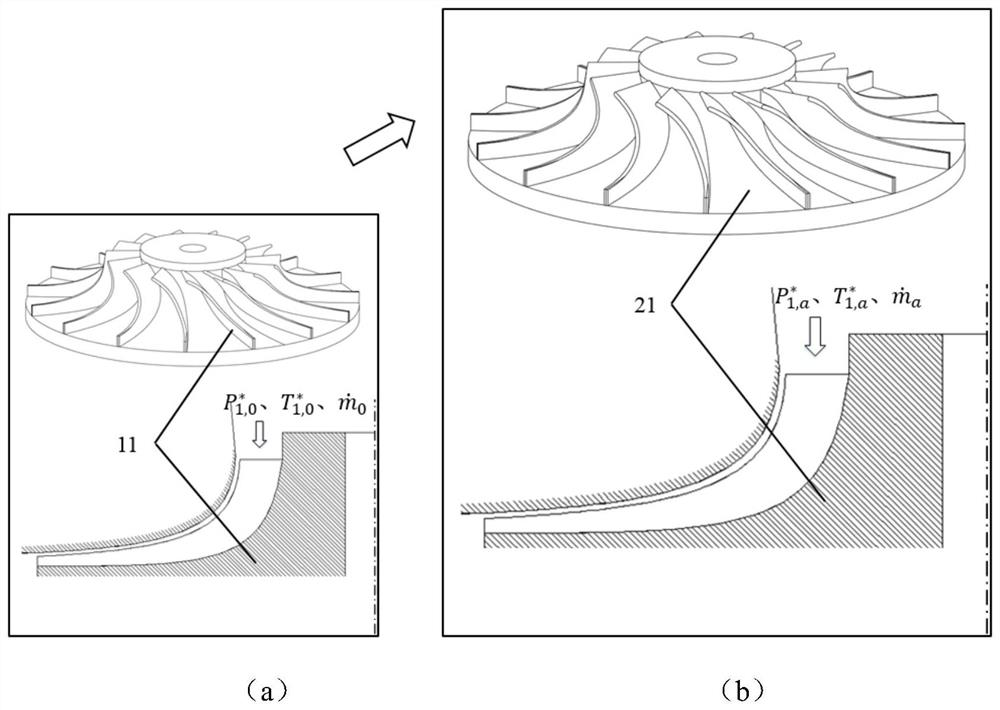

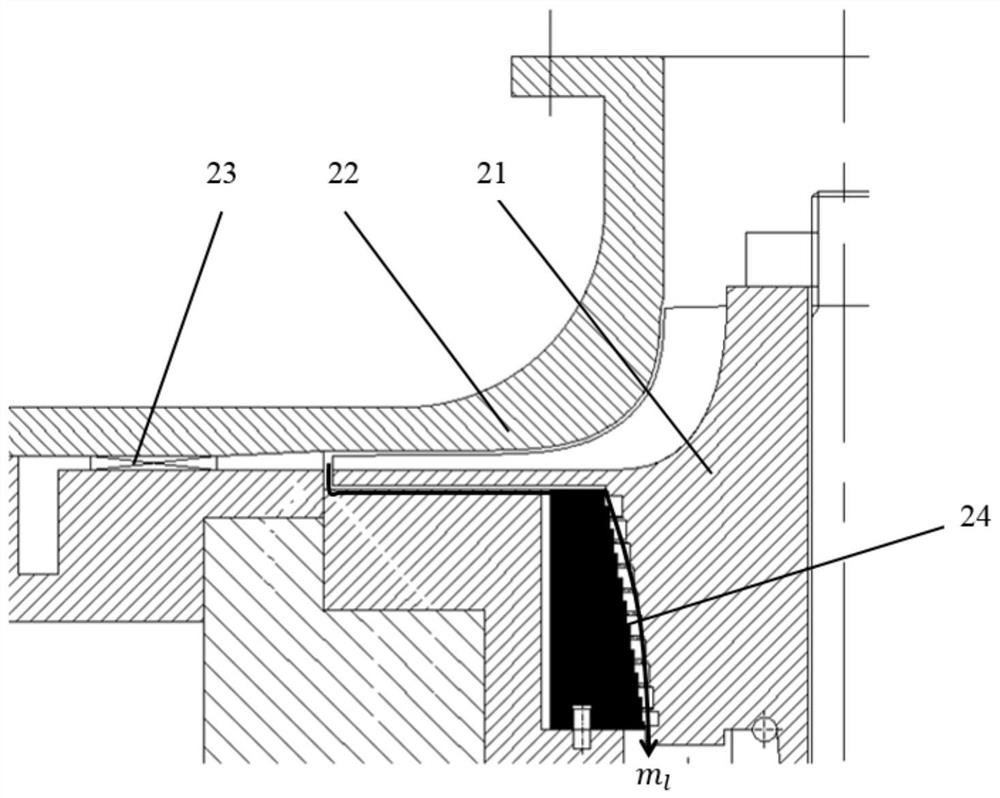

[0056] Specifically, the invention provides a similar modeling method for a supercritical carbon dioxide compressor test. First, according to the geometric similarity criterion, the geometric parameters of the test model are obtained by scaling. Then, according to the flow similarity criterion between different working fluids, the number of main criteria is consistent, and the operating parameters such as the speed, inlet pressure, inlet temperature, flow rate and other operating parameters of the air working fluid compressor are ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com