Brick masonry filled wood frame wall

A wood frame and brick masonry technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problem of long construction time, achieve the effect of improving the overall performance, improving the bearing capacity and energy consumption capacity, and delaying the horizontal joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

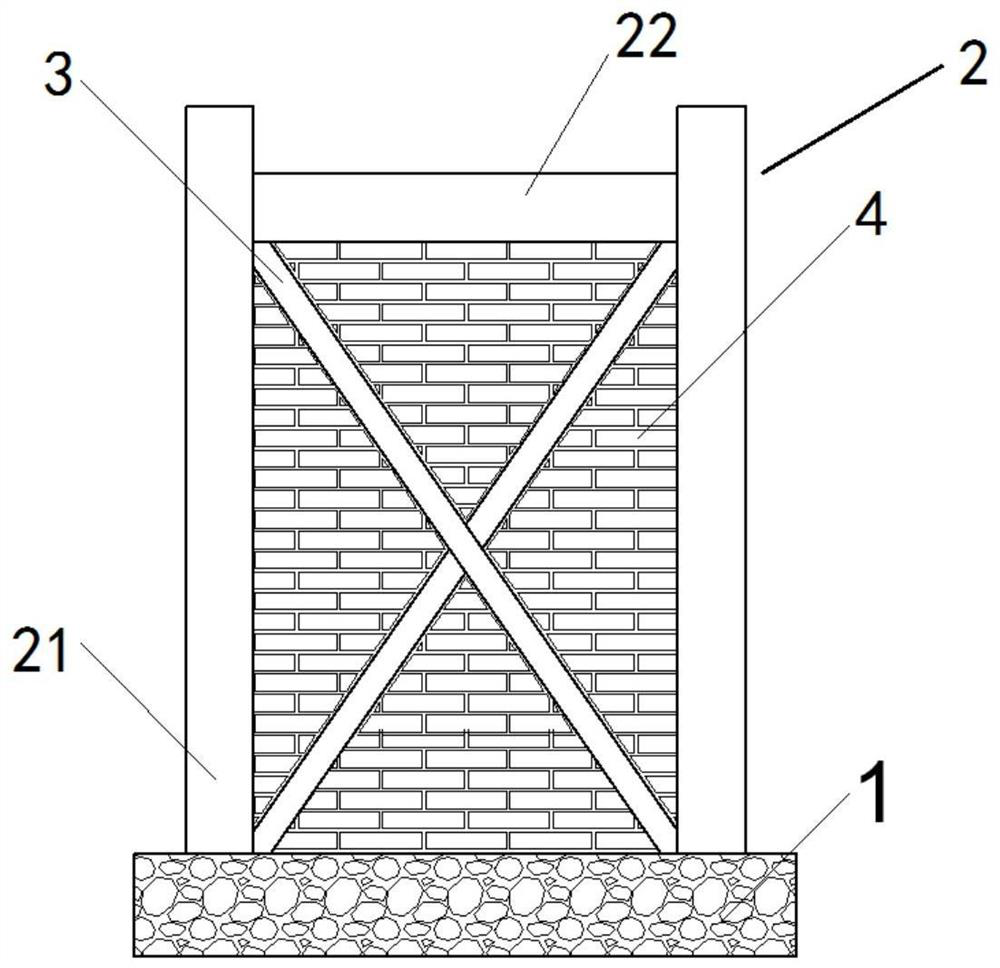

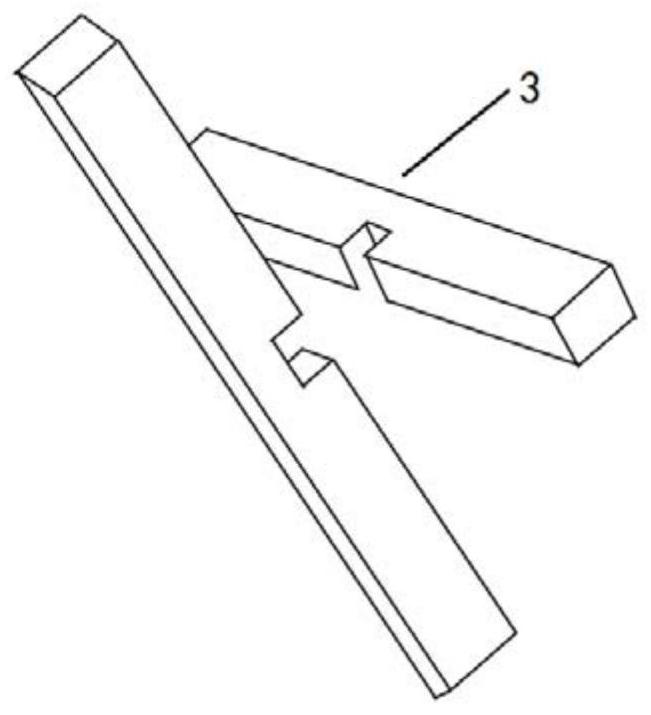

[0038] A brick masonry infill wood framed wall such as figure 1 As shown, it includes foundation 1, wooden frame 2, wooden diagonal brace 3 and brick masonry 4. The wooden frame 2 is rectangular, with an aspect ratio of 1.45:1. It is vertically installed on the foundation 1. The foundation 1 is made of concrete. Two wooden diagonal braces 3 are arranged in the wooden frame 2. The two wooden diagonal braces 3 cross each other in an X shape. Four blocks are formed between the brace 3 and the wooden frame 2, and the brick masonry 4 is fully built in the blocks.

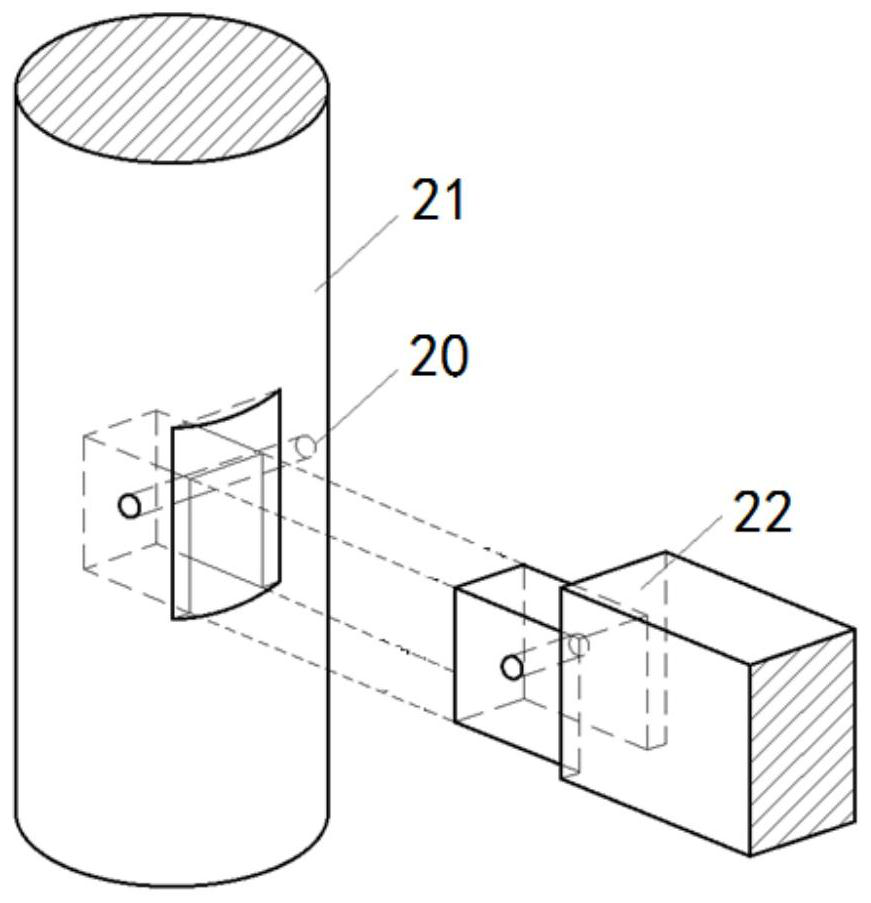

[0039] Both the wooden frame 2 and the wooden diagonal brace 3 are made of Douglas pine, such as figure 2 As shown, the wooden frame 2 includes a wooden column 21 and a wooden beam 22 connected by mortise and tenon, and a wooden pin 20 is arranged at the tenon and tenon joint, and the wooden beam 22 is horizontally connected to the wooden column 21, and the cross section of the wooden column 21 is 200 mm in diameter. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com