Corrugated lattice web reinforced composite material sandwich structure and preparation method thereof

A technology for reinforcing composite materials and sandwich structures, applied in chemical instruments and methods, wood layered products, synthetic resin layered products, etc., can solve problems of weak bonding performance, low compressive and shearing resistance, and small contact area and other problems, to achieve the effect of reducing elastic mutation, improving failure mode and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

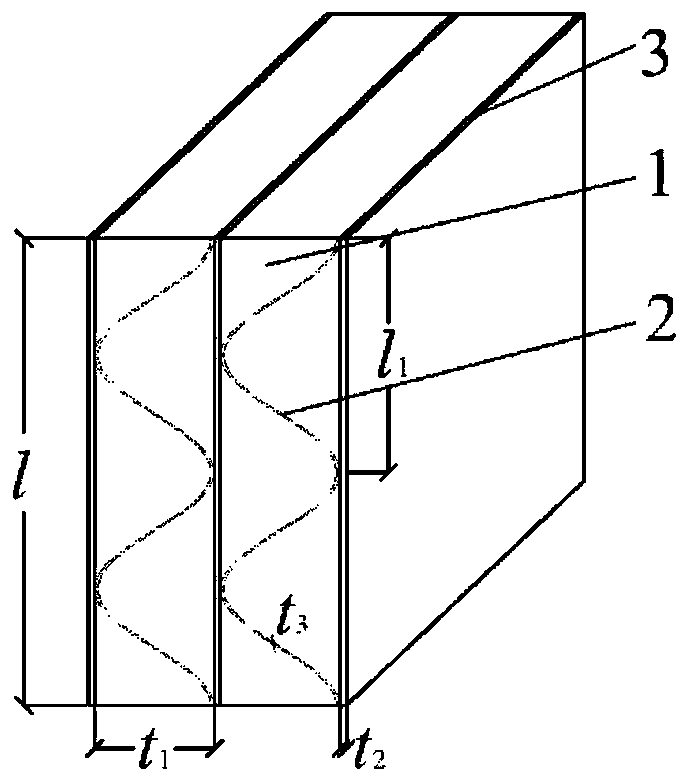

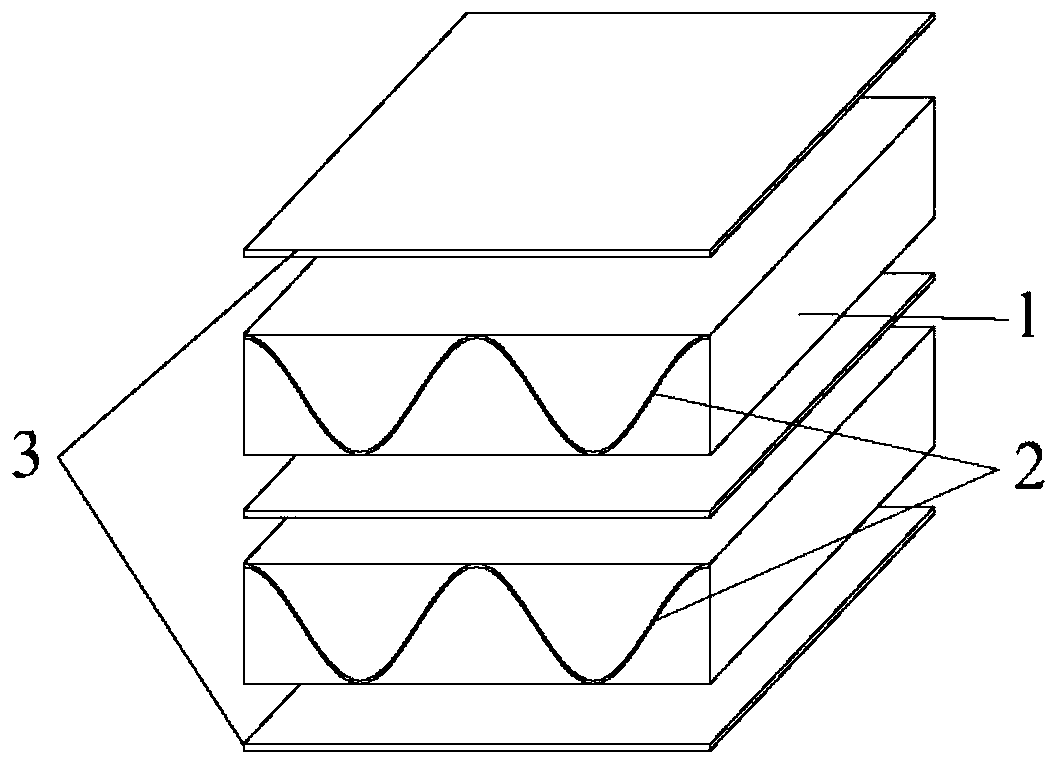

[0027] like figure 1 , figure 2 As shown, a corrugated lattice web reinforced composite material sandwich structure includes a core material 1, a corrugated lattice web 2 and a fiber panel layer 3;

[0028] The sandwich structure is a double-layer structure in which two core materials 1 are stacked together, and each core material 1 is cut in a wave shape in the thickness direction, adjacent core materials 1 are cut vertically along the same direction of the chord, and filled at the cut position The fiber cloth is introduced into the resin to form the corrugated lattice web 2, the upper and lower surfaces of the core material 1 are wrapped with the fiber cloth and cured with the resin to form the fiber panel layer 3, and the fiber cloth is one layer.

[0029] The core material 1 is polyurethane foam, the fiber panel layer 3 is uniaxial carbon fiber cloth, and the resin is unsaturated polyester.

[0030] The preparation method of the above-mentioned corrugated lattice web re...

Embodiment 2

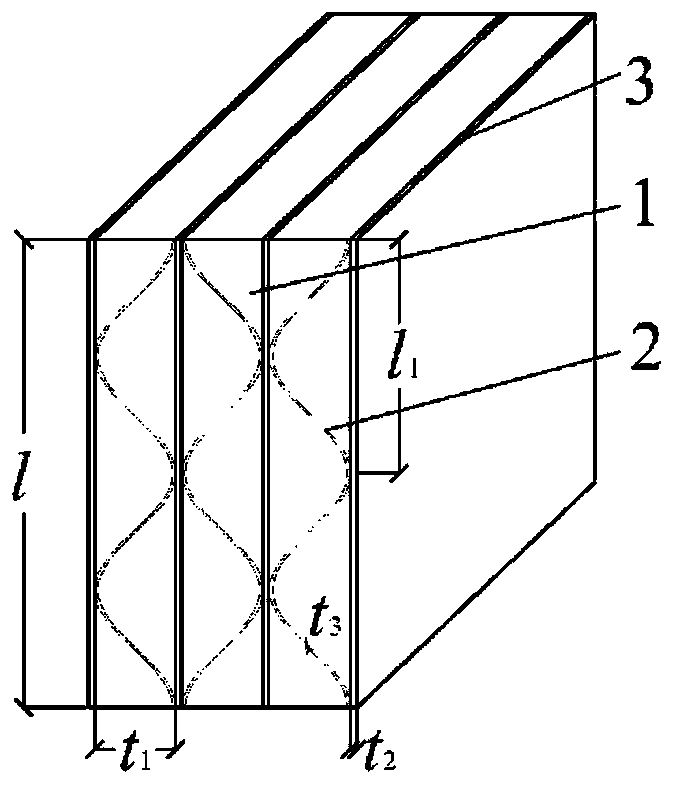

[0037] like image 3 As shown, a corrugated lattice web reinforced composite material sandwich structure includes a core material 1, a corrugated lattice web 2 and a fiber panel layer 3;

[0038] The sandwich structure is a three-layer structure in which three core materials 1 are stacked together. Each core material 1 is cut in a wave-like manner in the thickness direction, and adjacent core materials 1 are cut vertically along the chord direction and filled at the cut position. The fiber cloth is introduced into the resin to form the corrugated lattice web 2. The upper and lower surfaces of the core material 1 wrap the fiber cloth and solidify with the resin to form the fiber panel layer 3. The fiber cloth is multi-layered.

[0039] The core material 1 is paulownia wood, the fiber face layer 3 is glass fiber cloth, and the resin includes vinyl resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com