Buckling-resistant brace for energy-dissipating components constrained by ferrules

A technology of anti-buckling support and ferrule, which is applied in the direction of building components, earthquake resistance, building types, etc., to achieve the effect of optimizing the failure mode, avoiding the influence of residual stress, and improving energy consumption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

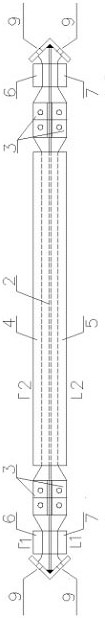

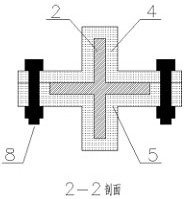

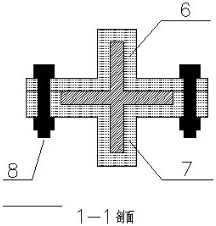

[0007] Such as Figure 1~Figure 9 As shown, the present invention is an anti-buckling support of ferrule-constrained energy-dissipating components, and a buckling-resistant support with replaceable ductile casting standard parts, including ductile casting standard parts 1, ductile casting cross cores 2, angle steel connectors 3, Cross core upper ferrule 4, cross core lower ferrule 5, energy dissipation section upper ferrule 6, energy dissipation section lower ferrule 7, high strength bolt 8, bolt hole 9, ductile casting standard part 1 by connecting section 10, transition section 11 and energy dissipating section 12 are integrally composed of three parts; the ductile casting standard part 1 and the ductile casting cross core 2 are spliced by high-strength bolts 8 through four angle steel connectors 3 to form a buckling-proof system with replaceable ductile casting standard parts The energy-dissipating member is supported; the energy-dissipating section 12 and the ductile cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com