Welding method and application of maritime work high-strength steel plates

A technology of high-strength steel plates and welding methods, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as uneconomical, low impact absorption energy of welds, and difficulty in meeting the requirements of classification societies , to achieve the effect of reducing thermal energy consumption, high economy, and reducing welding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 50mm thickness Q500E horizontal butt welding, specific process and implementation steps:

[0030] ① Welding materials

[0031] Flux cored wire YCJ551K2, specification Φ1.2; CO 2 Gas, purity 99.95%; welding parameters: current 220~230A, voltage 26~27V, welding speed 36~42cm / min.

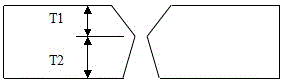

[0032] ② Groove form

[0033] Take an asymmetrical X-groove (such as figure 1 As shown), the groove angle is 45° on the T1 side and 40° on the T2 side, leaving a gap of 2mm at the root of the groove, and the thickness of both sides is 22mm on the T1 side and 28mm on the T2 side.

[0034] ③The implementation steps are:

[0035] First, arrange far-infrared heating devices on both sides of the steel plate, preheat to 100 ° C ~ 150 ° C within 500 mm from the groove, and use thermal insulation blankets to prevent heat dissipation.

[0036] Secondly, on the deep side of the groove (T2 side), use YCJ551K2 flux-cored wire for back welding of 3~4 layers, the welding thickness is about 14mm, and the...

Embodiment 2

[0060] 60mm thickness Q500E horizontal T-joint welding, specific process and implementation steps:

[0061] ① Welding material

[0062] Flux cored wire YCJ551K2, specification Φ1.2; CO 2Gas, purity 99.95%; welding parameters: current 220~230A, voltage 26~27V, welding speed 36~42cm / min.

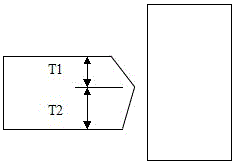

[0063] ② Groove form

[0064] Take an asymmetrical K-groove (such as figure 2 As shown), the groove angle is 40° on the T1 side and 40° on the T2 side, leaving a gap of 2mm at the root of the groove, and the thickness of both sides is 27mm on the T1 side and 33mm on the T2 side.

[0065] ③The implementation steps are:

[0066] First, arrange far-infrared heating devices on both sides of the steel plate, preheat to 100 ° C ~ 150 ° C within 500 mm from the groove, and use thermal insulation blankets to prevent heat dissipation.

[0067] Secondly, on the deep side of the groove (T2 side), use YCJ551K2 flux-cored wire for back welding of 3~4 layers, the welding thickness is about 14mm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com