Steel tube welding system and technology

A welding system and steel pipe technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of observing the best initial position of the steel plate, insufficient contact between the steel plate and the pipe, and the influence of the initial height grinding work, etc. The effect of handling pipes, safe and convenient use, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

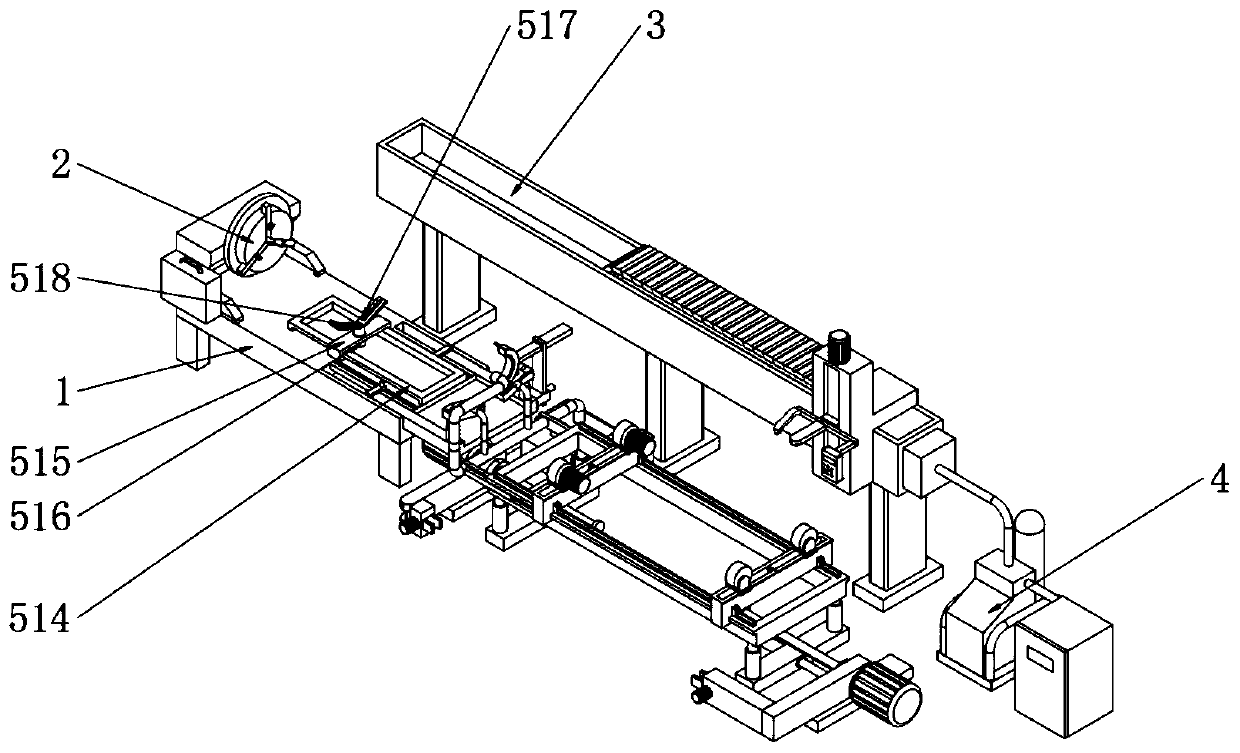

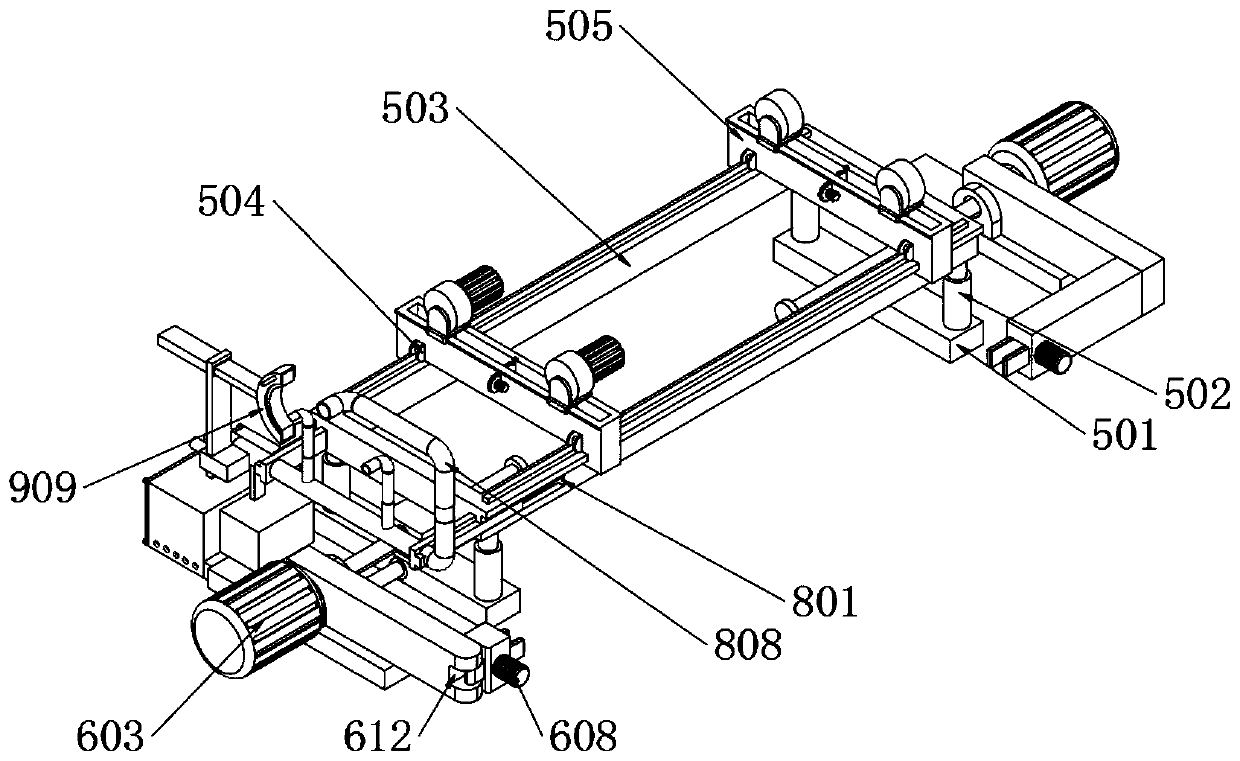

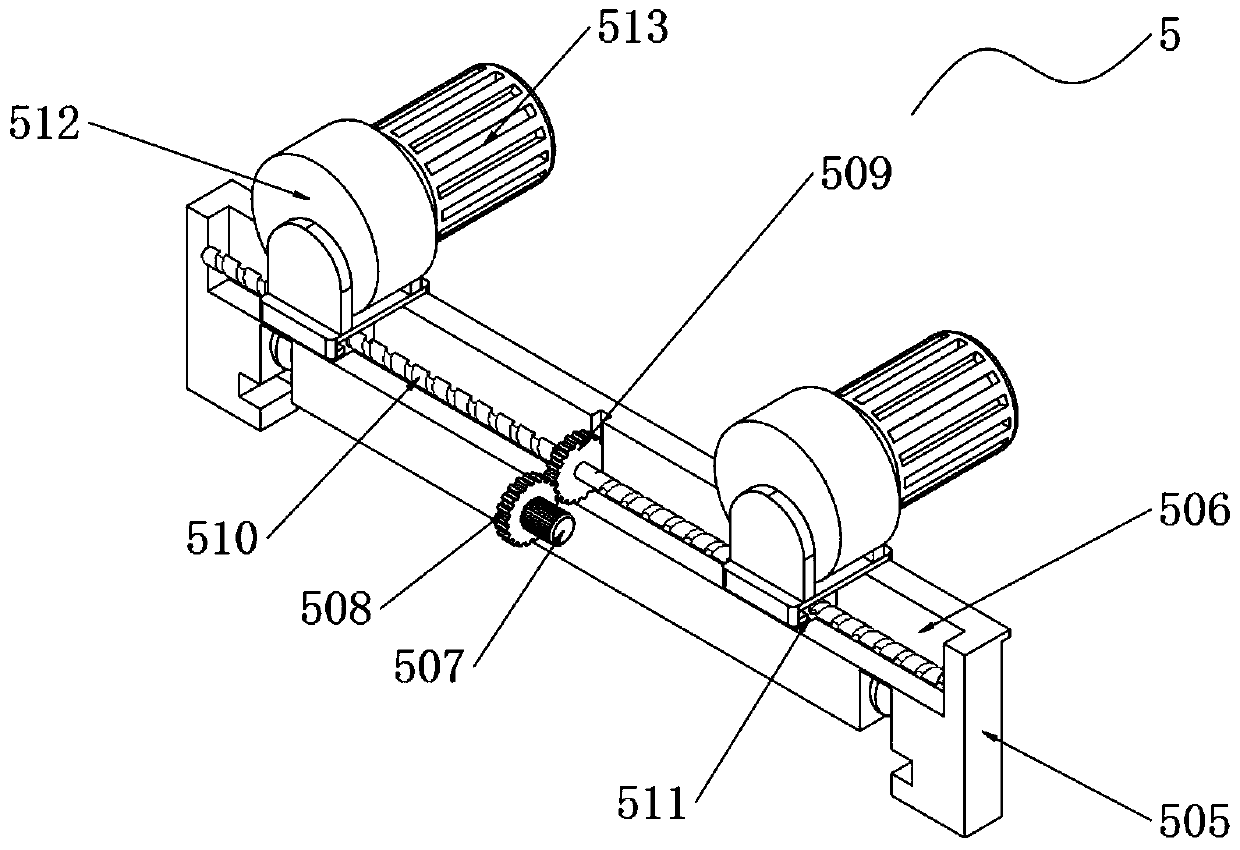

[0037] Example: such as Figure 1-13As shown, a steel pipe welding system includes a welding support frame 1, a support adjustment assembly 5, a feeding fastening assembly 6, a grinding preheating assembly 7, a chip removal and degassing assembly 8, and a heat preservation and cooling assembly 9. The grinding preheating assembly The side wall of the preheating installation groove 708 of the component 7 is fixedly connected with a detection motor 715, and the output shaft of the detection motor 715 is fixedly connected with the rotating column 716 located in the preheating installation groove 708, and the upper end of the rotating column 716 with a sliding space 717 is open and closed. Built-in pressure column 718, the bottom end of pressure column 718 is fixedly connected with the bottom wall of sliding space 717 through return spring 719, the bottom wall of sliding space 717 is fixedly connected with contact pressure sensor 720, the two sides of pressure column 718 are fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com