An all-metal soluble fracturing segmenter

An all-metal, segmenter technology, applied in the direction of wellbore/well components, production fluid, sealing/isolation, etc., can solve the problems of no belt displacement, bridge plug/ball seat slipping, and tight sealing, etc., to achieve Save the cost of drilling and grinding, avoid the effect of poor sealing, simple and effective structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

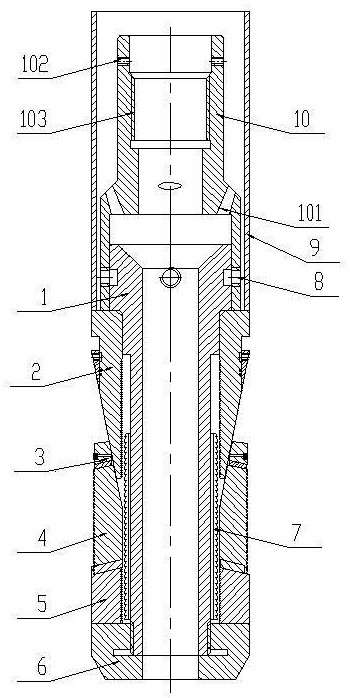

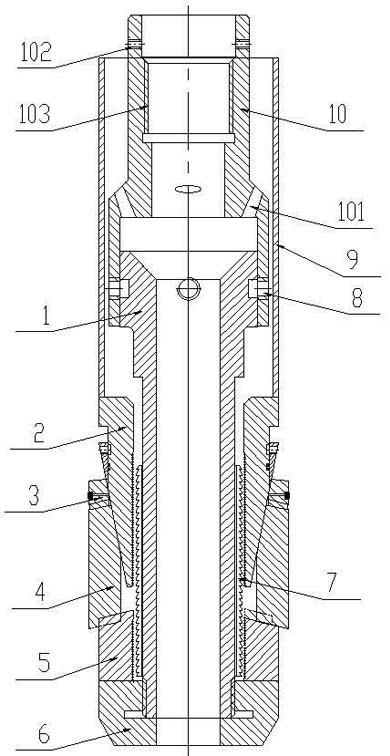

[0041] Such as figure 1 As shown, this embodiment provides an all-metal soluble fracturing segmenter, including a pull rod 1, a cone 2, a sealing system 3, an anchoring system 4, a push-pull ring 5, a bumper ring 6 and a lock ring 7 , the cone 2, the lock ring 7 and the anti-collision ring 6 are sleeved on the handle bar 1 from top to bottom in sequence, and the anchor system 4 and the push-pull ring 5 are sleeved on the lock ring 7 from top to bottom , the sealing system 3 is sleeved on the lower end of the cone 2, the upper end of the anchoring system 4 is overlapped on the cone 2, and the upper and lower ends of the anchoring system 4 are in contact with the sealing system 3 and the push-pull ring 5 respectively, The lower end of the push-pull ring 5 abuts against the anti-collision ring 6, and the upper side of the throwing handle 1 is provided with an upper end throwing mechanism, and the upper end throwing mechanism includes a push cylinder 9, an adapter 10 and a connect...

Embodiment 2

[0052] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0053] Such as Figure 8 As shown, the diameter of the anti-blocking channel in the center pipe is 35mm. When the wellbore is an upturned well, setting with displacement is required. That is to say, the wellbore is inclined upwards, and the pumped liquid needs to bear against the device without sliding down, and then start the setting seal. The anti-blocking channel of this patent has a channel with an inner diameter of 35mm, and has a certain displacement to meet the institutional requirements of an upturned well.

[0054] The upper end of the outer wall of the central tube is provided with a shear nail hole that cooperates with the connection system 8, and the lower side of the shear nail hole on the outer wall of the central tube is provided with a two-stage stepped boss whose diameter decreases from top to bottom. The upper side of the large diameter end of the step boss is abutted ...

Embodiment 3

[0058] This embodiment is further optimized on the basis of embodiment 1 or 2, specifically:

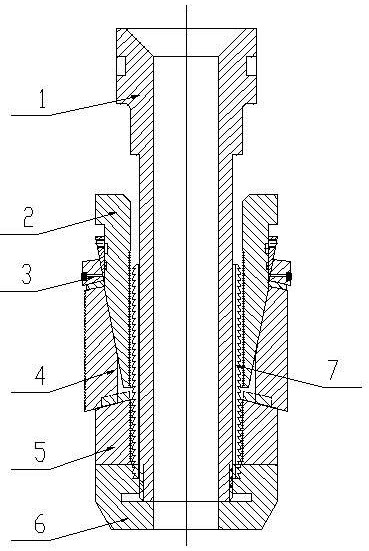

[0059] Such as Figure 11 As shown, the cone 2 includes a large cone 21 sleeved on the central tube and a small cone 22 sleeved on the upper straight section of the large cone 21. The large cone 21 and the small cone 22 pass through the shear nails 23 Connect, have sealing groove between big cone 21 and small cone 22, sealing ring 24 is housed in the sealing groove. The cone is designed to be two in size, which can effectively alleviate the interference problem. When the axial pressure increases, the slips and the sealing system climb up on the large and small cones, and the slips are first anchored on the casing. When the pressure continues to increase, the shear nails between the large and small cones are cut off, and the sealing The system can continue to climb until the sealing is complete. This structure effectively solves the problem of interference and avoids the risk of poo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com